Abstract

Genetically improved persistency of commercial laying hens enables egg producers to keep flocks longer in production, provided egg shell quality can be maintained. Only healthy birds with a functioning calcium metabolism can show their genetic potential for lifetime number of salable shell eggs. Optimal management for lifetime production of shell eggs starts during the rearing period. Pre-lay feeding at transfer to the laying house is critical to meet the changing nutritional needs of birds as they start to lay eggs. Feeding and nutrition to assure liver and gut health supports egg shell quality. High quality limestone with fine and coarse structure should be adapted to the changing needs of the hens with progressing age and during each day. Split feeding has been developed and is increasingly applied in practice to meet the varying demand for calcium during the day. Limiting the increase of egg weight in extended production cycles helps to maintain shell quality.

Keywords

laying hens, nutrition, egg shell quality, calcium supply, persistency

Introduction

Modern white egg and brown egg layers exhibit a very high production potential in different housing systems and may be kept up to 80 weeks in production, without molting. Egg producers recognize the results of ongoing genetic selection in terms of increasing persistency of rate of lay and feed conversion ratio. The increase in hen-housed egg production is mainly due to longer clutch length and improved uniformity of layer flocks. A popular goal is 500 eggs in one cycle, and this has already been surpassed in many flocks. Most egg producers realize declining egg shell quality as a limiting factor toward the end of a long laying cycle and focus on calcium nutrition earlier in the life of the next flock. The “post-peak-dip” is another challenge early in the production period. Optimal nutrition can help to minimize problems at these two critical times in the life of a flock, to secure a good start of production, a high peak rate of lay close to 100% and best possible egg shell quality beyond 90 weeks of age.Importance of rearing and pre-lay phase

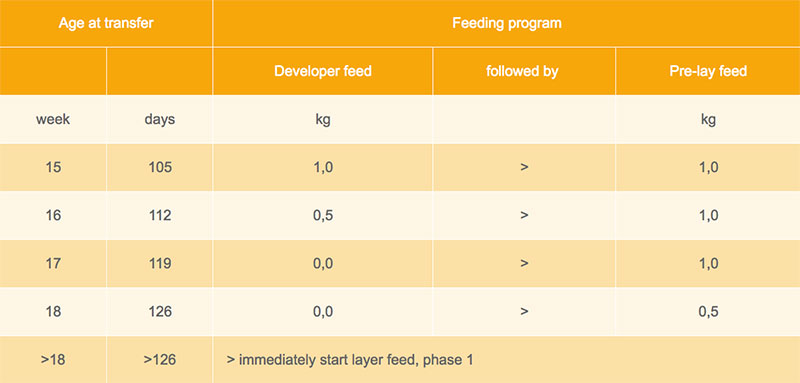

Optimal layer nutrition for a lifetime starts directly after hatch. This means to fulfil the nutritional demand for rapid growth during the first half of the rearing period followed by slow growth and nutritional consequences in the second half of the rearing period. The feeding program during the first half of the rearing period needs to focus on an optimal supply of digestible amino acids and minerals to ensure the basic growth of the inner organs, muscles and skeleton (Leeson and Summers, 1997). During the second half of the rearing phase the physiological development of the pullet continues at a slower rate, which offers the chance for training feed intake behavior of the pullets, which is critical for the following start of egg production, when today’s layers tend to eat too little. During the second half of the rearing phase the reduced demand for protein and amino acids offers a chance to include raw materials with lower density and higher crude fiber content. Provided suitable raw materials are available, I recommend at least 5.5 % crude fiber during this phase. At the end of the rearing period, the birds change from a pullet to a laying hen, and nearly all metabolic processes change. While the medullary bones develop and all metabolic processes change to egg production, the birds must continue to gain weight. The development of the medullary bones takes roughly ten days, requires additional calcium and is called the pre-lay period (Coelho, 2001).Pre-lay rations support a smooth transition from developer feed to layer feed, with 2 – 2.5 % calcium, while the other nutrients are similar to a layer feed. The major challenge to implement pre-lay feeding is logistics and correct use on the farm. As shown in table 1, I suggest using pre-lay feed for about ten days, with a maximum of 1 kg per pullet. Common mistakes are feeding pre-lay feed too early or for too long, which may result in poor peak rate of lay.

Pre-lay rations help the birds to adapt to the high calcium content of layer feed and to maintain sufficient daily feed intake. Higher levels of protein and amino acids allow late maturing birds to catch up in development, with positive effects on the uniformity of the flocks, and the calcium content prevents decalcification of bones of early maturing hens. Positive results of pre-lay feeding have been shown around the world in different production systems, and it is highly recommended to implement pre-lay feeding as a general practice for pullet flocks.

Table 1: Suggested use of pre-lay feed

Support of liver health

After an optimal start into the laying period the liver is the most important organ of the hen. Feeding on liver health is not only a veterinary issue but an important nutritional topic as well. The liver provides nearly all basic nutrients for the development of the yolk and albumen and supports the development of the egg shell: the liver provides the protein in the egg shell, which contributes to elasticity of the egg shell. Adding fat and oil or crude fat in layer diets is a well-known tool to reduce the incidence of “fatty liver syndrome”. Recommended and widely used in practice is also added choline chloride in layer diets to support liver metabolism. Every fatty liver supplement is based on choline chloride and vitamins like K3, E, B12, B1 and folic acid. Sometimes Methionine and Betaine are used to relieve liver metabolism. Contamination of layer feeds with mycotoxins may be the cause of liver damage. Don’t wait until a veterinary laboratory confirms liver damage in post-mortem examination and be aware of the potential risk of mycotoxin contamination. Recommendations for feed additives vary, and egg producers must decide when to use a mycotoxin binder.Source and quality of limestone

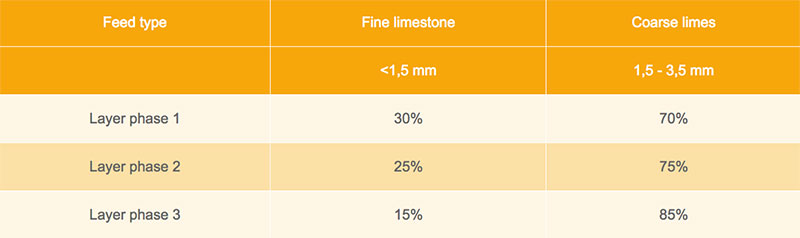

Limestone is the most important and usually cheapest ingredient of layer rations to support egg shell quality, but the quality is not always optimal. As a laying hen’s demand for calcium varies during a 24 hour day, fine and coarse limestone with different solubility should be offered as standard practice (Zhang et al., 1997). Another source of calcium for egg shell formation is the complex of medullary bones, which store and release calcium during the night when the hens normally have no feed intake. Relying too much on the medullary bones, however, leads to a loss of phosphorus and bone strength. Therefore the feeding strategy should focus on sufficient limestone supply “just-in-time” from the gut and minimizing the utilization of calcium from the medullary bones for egg shell formation (Rao and Roland, 1990). The average retention of calcium from limestone in layer feeds varies between 40 – 60%, which means that about 50% of the limestone intake will be excreted with the feces.Solubility depends on particle size. I therefore recommend using two sources of limestone in layer diets, with at least 2/3 as coarse limestone. Table 2 shows the recommendations of Lohmann Tierzucht for LSL Classic white-egg layers. The effect is similar to adding oyster shells on top of compound feed when egg shell quality deteriorates with increasing age of the flock and decreasing efficiency of calcium metabolism. In deep litter and aviary systems feeding coarse particle size of limestone appears to have a positive effect on bird behavior, and flocks on this program seem to be more docile. A similar effect can be observed when flocks are offered grit, i.e. small insoluble stones, to support gizzard activity as a natural grinder.

Table 2: Recommended ratio of fine and coarse limestone

Daily calcium intake and timing during the day

Nutritionists should know the daily demand for optimal egg shell developmentand take the actual feed intake of a specific flock into account to ensure sufficient intake of calcium. For example, when 4.1 gram of calcium intake per hen per day is the target, then a ration with 4.5% Ca will be required in case of 90 gram daily feed intake or 3.4% Ca for 120 gram daily feed intake. Unless the actual daily feed intake is taken into account, many laying hens may be harmed at an early stage of the laying period (Roland and Gordon, 1999). Observations of feed intake behavior suggest that the hens consume roughly 1/3 of the daily amount during the first half of the day and 2/3 during the second half of the day. Feed composition during the afternoon is important to meet the higher demand for calcium during the night when most of the egg shell formation takes place. Many layer farms are therefore using a top dressing of 1-2% coarse limestone in compound layer feed for the last feeding of the day. Another possibility is “split feeding”, with a lower Ca morning feed and a higher Ca afternoon feed. Either approach can be recommended from a nutritional point of view. The major challenge for implementation in practice is related to feed logistics and equipment in the layer house.Controlling egg size

Shell strength is negatively correlated with egg size. At the beginning of a laying cycle, all hens lay smaller eggs with thicker shells, at the end of the laying cycle larger eggs with thinner shells. To some extent the increase of egg size in aging flocks can be controlled by nutritional management, and this helps to maintain adequate shell quality in extended production cycles when the calcium metabolism becomes less efficient. A recent survey involving 30 flocks of Lohmann Brown Classic in France has shown a variation of +/- 2.5 gram of average egg weight between flocks with the same genetic background. If a nutritionist is asked to formulate feed rations which help to reach 55-60 grams as early as possible and to limit the increase beyond 63 grams, he would first consider the content of Methionine and Sulphur amino acids and crude protein to balance the amino acid profile. Added fat and oil or crude fat and the content of linoleic acid are the next variables to consider. The basic demand for linoleic acid is about 1% in layer diets and can easily be met in practice. Scientific experiments and field experience from many countries have shown that egg weight will increase with linoleic acid levels of 2% or even 3% in commercial layer diets (Garrelfs, 2010). Therefore it is suggested to start with a higher linoleic acid level at the beginning of the laying period and to decrease the content toward the end of the laying period. It has become common practice to reduce the nutrient density of the feed during the laying period in order to reduce feed costs and at the same time control the egg size. But laying hens will try to adjust their feed intake to meet their energy demand and will respond to the reduction of nutrient density and energy of the formula by increased feed intake, with more amino acids and crude protein than they need. Therefore I would recommend to keep the level of energy constant throughout the laying period and to reduce amino acids and crude protein.Feeding with focus on gut health

Gut health has become a popular topic in connection with the reduced use of antibiotics and novel feed supplements with antibiotic activity. A healthy gut ensures optimal nutrient and mineral absorption and is essential for shell quality (Roberts, 2008). The feed industry and nutritionists are offering feed additives and many ideas to support gut health; feed enzymes are widely used; herbs, spices and essential oils; acidifiers and organic acids; probiotics and prebiotics (MOS); medium and short chain fatty acid products; inclusion of nondigestible fiber (Lignin).The gizzard deserves more attention for its grinding function before the digestive process can start. The gizzard is basically a muscle which needs stimulation. If the gizzard is filled with coarse feed, it will grind and mix feed particles before passing them on into the intestine. If the gizzard is filled with too much fine feed, it cannot function properly and may cause diarrhea, wet litter and dirty eggs. Therefore a coarse feed structure is recommended. Larger feed particles have an increased retention time in the crop and the gizzard, which stimulates the ph drop and has a bactericide effect. An excess of feed particles smaller than 1mm causes a shortcut through the gizzard without utilization.

Most laying hens around the world get mash feed. Coarseness and homogeneity of this type of feed affect a healthy digestion, dry litter and clean eggs. Homogeneous structure limits the birds’ preferential intake of larger particles and reduces competitive behavior at the feeders. An attractive structure supports sufficient intake of all essential nutrients. Pelleting and crumbling compound feed may help to utilize fine feed components, but the best results are usually obtained with mash feed.

Summary and conclusions

The recommendations for optimal feeding of layers for extended laying periods of 100 weeks include:- start during the rearing phase to prepare pullets for a long productive life

- optimize the conditions during transfer with pre-lay feeding

- assure sufficient daily nutrient intake during the early stage of production

- ay special attention to liver health and gut health throughout the life cycle

- use high quality Ca sources with fine and coarse structure and adapt ratio

- control egg weight in aging flocks

Egg shell quality determines how long a layer flock can be kept. Nutritionists and veterinarians can advise the management how to increase the profitability of egg production. For an extended production cycle of laying hens, optimal nutrition starts just after hatch to develop a pullet flock with optimal body weight, uniformity and feed intake capacity. During the physiological transition period when pullets become sexually mature and ready to lay the first egg it is important to minimize stress connected with the transfer from rearing to the layer house. Pre-lay feeding is highly recommended to assure sufficient nutrient intake to meet the growin demand before rate of lay approaches a peak near 100%. Throughout the laying period, optimal quality of fine and coarse limestone should be used, in a ratio adjusted to the age of the flock and, where possible, applying the concept of “split feeding” to maximize the availability of Ca for shell formation during the night. Feed structure affects feeding behavior and nutrient intake and should be designed to support a healthy gut.

Literature

Coelho, M. (2001) Involvement of calcium and phosphorus in bone and shell quality of early maturing commercials layers. World Poultry 17(6): 16-19.Garrelfs, Inga (2010) Einfluss unterschiedlicher Gehalte des Futters an Linolsäure auf das Eigewicht bei LSL und LB. Presentation, FH Osnabrück.

Leeson, S. and L. Summers (1997) Layer performance of four strains of Leghorn pullets subjected to various rearing programs. Poultry Sci. 78: 1-5.

Lohmann Tierzucht GmbH (2014) Management Guide LSL-Classic.

Rao, K.S. and D.A. Roland (1990) In vivo limestone solubility in commercial Leghorns: Role of dietary level, limestone particle size, in vitro limestone solubility rate and the calcium status of the hen. Poultry Sci. 69: 2120-2176.

Roberts, Juliet R. (2008) Egg Shell Quality. Animal Science, School of Environmental and Rural Science, University of New England, Armidale, Australia.

Roland, D.A. and R.W. Gordon (1999) Phosphorus and calcium optimization in layer diets with phytase. In: M. Coelho and E.T. Kornegay, Ed. Phytase in animal nutrition and waste management.

Zhang, Bingfan and C.N. Coon (1997) The relationship of calcium intake, source, size, solubility in vitro and in vivo, and gizzard limestone retention in laying hens. Poultry Sci. 79: 1702-1706.

Abonnieren Sie unseren Newsletter

Und informieren Sie sich über die neuesten Nachrichten aus der Branche.