Summary

Life cycle assessment procedures were applied to compare the environmental impact of producing

broiler meat and eggs in different management systems. Input and output parameters used in the

calculations were obtained from the UK broiler and egg industry and are summarized in Tables 1 and

2. The environmental impact was expressed in terms of for criteria: (1) global warming potential GWP),

(2) Eutrophication potential (EP), (3) Acidification potential (AP) and (4) Primary energy use per unit

broiler meat or eggs. The results are shown in Tables 3 and 4.

There were relatively large differences in many categories of the environmental impacts between different UK broiler and egg production systems and generally these reflected the differences in the efficiency in production, feed consumption (and related production of manure) and material and energy use.

The methodology used in the current study with functional relationships between different activities related to animal production and mechanistic representation of biological processes provides a realistic tool for quantification of environmental impacts of various agricultural systems. This includes the quantifications of the overall uncertainties of the model outputs, which allows systematic comparison between different production systems.

There were relatively large differences in many categories of the environmental impacts between different UK broiler and egg production systems and generally these reflected the differences in the efficiency in production, feed consumption (and related production of manure) and material and energy use.

The methodology used in the current study with functional relationships between different activities related to animal production and mechanistic representation of biological processes provides a realistic tool for quantification of environmental impacts of various agricultural systems. This includes the quantifications of the overall uncertainties of the model outputs, which allows systematic comparison between different production systems.

Introduction

UK poultry production, including broilers and eggs, has been identified as being relatively environmentally friendly compared to the production of other animal commodities. However, like all agricultural systems, any current poultry system has scope to improve and reduce its environmental impacts even further.The aim of the work conducted at Newcastle University was to apply the environmental Life Cycle Assessment (LCA) method “from conception to farm gate”, to quantify the environmental burdens of the main broiler and egg production systems in the UK, and hence to identify the main opportunities to reduce these impacts within each system. The broiler systems included in the study were 1) standard indoor, 2) free range and 3) organic production and the egg production systems were 1) conventional cage, 2) barn, 3) free range and 4) organic laying. Although egg production in conventional cages has been banned by the EU and is not used in the UK anymore, it is still in use in some other European countries, and therefore the results for the cage laying system are also presented in this study. Results for enriched cages now used in the UK are expected to be broadly similar.

Environmental impact assessment methodology

The quantification of the environmental impacts of agricultural systems is demanding, since these systems include complicated links between different production sectors. For example, livestock production is closely connected to arable production, as it specifies the demand of the feed crops.Furthermore, livestock produces manure, which in turn is used as fertilizer when producing arable crops. There are also specific interactions and feedbacks within each livestock system, as for example in broiler production the level of productivity specifies the quantity of broiler chicks, breeder birds and so on required to produce a certain level of output (broiler meat). As a result, a consistent, quantitative calculation method is needed to handle the whole livestock production system and related activities.

A method called environmental Life Cycle Assessment (LCA) was used in this study to quantify the environmental impacts (caused for example by emissions of greenhouse gases to atmosphere or leaching of nutrients to environment) of broiler and egg production. LCA evaluates the scenarios systematically to account for all inputs and outputs that cross a specified system boundary and relates these to the “functional unit”. In this study, the functional unit was set as either 1000 kg of expected edible broiler carcass or 1000 kg eggs, and the modelled system was defined as “from cradle to farm gate”. The calculation method was based on a modelling framework describing the general structure of the industry, combined with process models and simulation models so that changes in one area of the system caused consistent interactions elsewhere. This approach was applied to both feed crop and animal production.

The structural model for broiler and egg systems combined all the main activities of the industry, and quantified the interactions between them. This framework was used to calculate all of the inputs required to produce the functional unit, taking into account the breeder, broiler, pullet and layer systems, and actual levels of productivity, feed conversion and mortality. It also calculated the outputs, both useful (broilers, eggs and spent hens) and unwanted. Changes in the proportion of any activity resulted in changes to the proportions of others in order to keep producing the desired amount of output.

An animal growth, production and feed intake model, based on actual biological processes, was used in this study in order to calculate the total consumption of each feed ingredient during the whole production cycle, and to calculate the amounts of main nutrients, nitrogen (N), phosphorus (P) and potassium (K) in manure produced by the birds during the production cycle. The model was calibrated to match the real production and feed intake data, provided by the UK poultry industry for different systems by adjusting the model parameters for growth rate, energy requirement for maintenance and egg production.

The model calculated the N, P and K contents of the manure according to the mass balance principle, i.e. the nutrients retained both in the animal body and eggs were subtracted from the total amount of nutrients obtained from the feed (including the additional nutrients obtained from foraging in free range and organic production). In addition to the nutrients excreted by the birds, nutrients in the spilled feed and uncollected eggs were added to the manure in the calculations. For the purpose of the study, it was assumed that all broiler, pullet, layer and breeder manure was transported for soil improvement, excluding the proportion that was excreted outside in the non-organic free range production systems.

A separate sub-model for arable production was used to quantify the environmental impacts of the main feed ingredients. The greenhouse gas emissions arising from land use change were taken into account according to the principles of the carbon footprinting method PAS 2050 (BSI, 2011). A separate sub-model was also used for manure emissions and the nutrient cycle. In the model, the main nutrients that were applied to the soil in manure were accounted for either as intake by crops or as losses to the environment. The benefits of N, P and K remaining in soil after land application of manure were credited to poultry by offsetting the need to apply synthetic fertilizers, or in the case of organic production, the need of dedicated legume and rock P and K.

When estimating the environmental impacts of any agricultural system, it should be noted that both the methods and the inputs contain uncertainties (e.g. model errors and variations in input data) which should be taken into account. For example, when comparing different production systems, statistical comparison of the outputs of the LCA model is only possible if the uncertainties in the inputs and the resulting overall uncertainty of the outputs are quantified. In this study, the uncertainties of the input variables were based on the data from the industry, and they also included potential errors of the models. The error distributions of the emission factors followed the IPCC (2006) guidelines. As a combination of these, the overall uncertainties of the outputs were estimated and used to determine the possible statistical significance of the differences between the systems.

Environmental impacts considered

The output of the LCA-systems model was the emissions to the environment in different poultry systems. The emissions were aggregated into environmentally functional groups as follows:Global Warming Potential (GWP) is a measure of the greenhouse gas emissions to the atmosphere, and was calculated here using a timescale of 100 years. The main sources of GWP are carbon dioxide (CO2) from fossil fuel and land use changes, nitrous oxide (N2O) and methane (CH4). GWP was quantified as CO2 equivalent: with a 100 year timescale 1 kg CH4 and N2O are equivalent to 25 and 298 kg CO2 respectively. The sum of GWP per functional unit is also known as the “carbon footprint”.

Eutrophication Potential (EP) is used to assess the over-supply of nutrients as a result of nutrients reaching water systems by leaching, run-off or atmospheric deposition. EP was calculated using the method of the Institute of Environmental Sciences (CML) at Leiden University (http://www.leidenuniv.nl/ interfac/cml/ssp/index.html). The main sources are nitrate (NO3-) and phosphate (PO4 3-) leaching to water and ammonia (NH3) emissions to air. EP was quantified in terms of phosphate equivalents: 1 kg NO3-N and NH3-N are equivalent to 0.44 and 0.43 kg PO4 3-, respectively.

Acidification Potential (AP) is mainly an indicator of potential reduction of soil pH. AP was also calculated using the method of the Institute of Environmental Sciences (CML) at Leiden University The main source is ammonia emissions, together with sulphur dioxide (SO2) from fossil fuel combustion.

AP was quantified in terms of SO2 equivalents: 1 kg NH3-N is equivalent to 2.3 kg SO2.

Primary Energy Use was quantified in terms of the primary energy needed for extraction and supply of energy carriers, including gas, oil, coal, nuclear and renewable. There are also other categories of environmental impacts, such as Abiotic Resource Use and Pesticide Use. These categories were not considered here because reliable estimates of the uncertainties of the related inputs were not available, and therefore the comparison between the systems would not have been meaningful.

Production systems considered

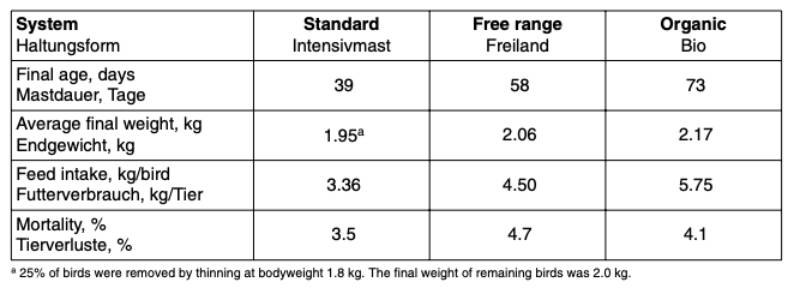

The production systems in this study were considered to represent typical UK broiler and egg production (Table 1 and Table 2 respectively). These figures, together with estimates of farm energy consumption (for heating, lighting, ventilation, feeding and incineration of dead birds) were based on average data from typical farms as provided by the industry.Table 1: Typical production and feed intake figures for the different broiler production

systems in UK as provided by the industry

Praxisübliche Mastdauer, Schlachtgewicht, Futterverbrauch und Verlustraten bei Broilermast in verschiedenen Produktionssystemen (Leinonen et al., 2012a)

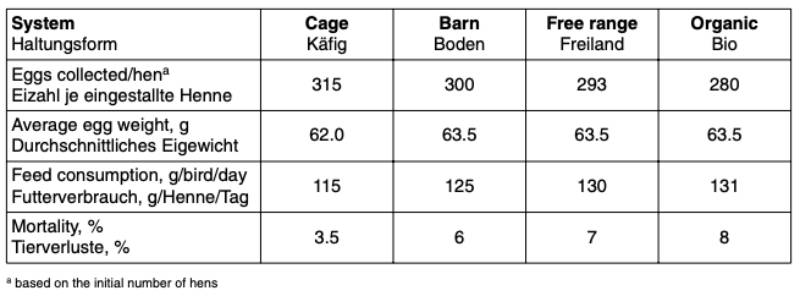

Table 2: Typical production and feed intake figures for the different egg production systems

in UK as provided by the industry

Praxisübliche Legeleistung, durchschnittliches Eigewicht, täglicher Futterverbrauch und Tierverluste in verschiedenen Produktionssystemen (Leinonen et al., 2012b)

The baseline diets representative of those used in the UK were constructed using information provided

by the poultry industry. The broiler diets included four and the layer diets five separate phases,

according to common practice. Separate diets for broiler breeders were also specified.

The baseline diets representative of those used in the UK were constructed using information provided

by the poultry industry. The broiler diets included four and the layer diets five separate phases,

according to common practice. Separate diets for broiler breeders were also specified.

Estimates of environmental impacts for broilers

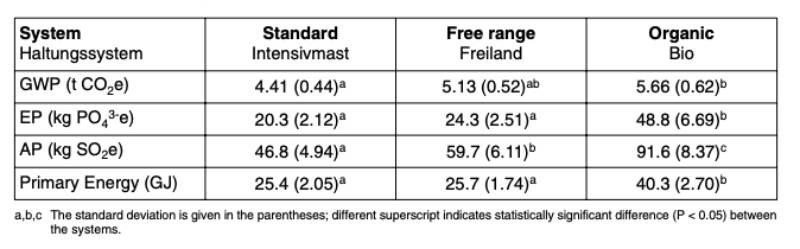

The number of broiler birds required to produce the expected edible carcass weight of 1000 kg was higher in the standard indoor system than in the free range and organic systems because the finishing weight was lowest in the standard indoor system. The length of the production cycle was much higher in free range and organic systems than in the standard indoor system, thus the feed consumption per bird was also higher in these systems. This had a major effect on the trends in environmental burdens (Table 3).Table 3: Global Warming Potential (GWP), Eutrophication Potential (EP), Acidification Potential

(AP) and Primary Energy Use per 1000 kg of expected edible carcass weight in the

main broiler production systems in the UK.

Erderwärmung (GWP), Eutrophierung (EP), Versäuerung von Böden und Gewässern (AP) sowie Primärenergieverbrauch zur Produktion von 1000 kg Broilerfleisch (Leinonen et al., 2012a)

In many of the environmental impact categories, feed caused relatively higher impacts than any other materials involved in broiler production, for example 71 – 72% of the total GWP and 65 – 81% of the Primary Energy Use of the system. The GWP was affected by relatively high CO2 emissions from the production and transport of some feed ingredients (e.g. non-organic soya, palm oil, fish meal and pure amino acids) in the standard and non-organic free range broiler diets. On the other hand, organic feed had generally much higher impact than the non-organic feed in other impact categories, especially EP. Although the emissions per land area are sometimes lower in organic crop production compared to non-organic, the yields are generally much lower as fertility building and cover crops are required, and this makes the emissions higher per unit of the product.

Emissions from manure were the main component of AP in broiler production and had also a relatively high contribution to EP. This was mainly a result of ammonia emissions, which contributed to both these potentials, together with nitrate leaching (affecting only EP). The AP from manure was especially high in the organic system.

Estimates of environmental impacts for eggs

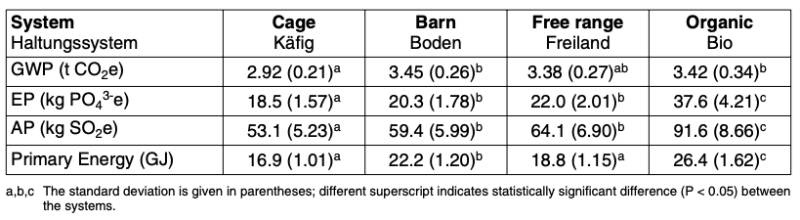

The production of 1000 kg eggs required 51.2 laying birds in the cage system, 52.6 in the barn system, 53.8 in the free range system and 56.3 in the organic system. This general trend in productivity also affected other aspects of the activity data, such as feed consumption. Furthermore, the average feed consumption per bird was also higher in the alternative systems than in the cage system. Much of the explanation of the trends in environmental burdens that followed resulted from these differences in the efficiency of the systems (Table 4).As in the broiler systems, feed was the biggest component of GWP in egg production (contributing 64 – 72% to the overall GWP and 54 – 75 % to the overall Primary Energy Use of the systems). Compared with broiler production, the farm electricity use had a higher relative contribution to GWP and Primary Energy Use, especially in barn egg production. Again, manure was a major source of both EP and AP, which were especially high in the organic egg production system.

Discussion

The results of this study show that the environmental impacts of both broiler and egg production are largely related to the efficiency of resource use of each system. In broilers, the standard indoor system had a shorter production cycle compared to the alternative systems, and therefore also lowest feed consumption and manure production per functional unit. Also in egg production, the alternative systems were generally less efficient than the cage system, and therefore had also higher environmental impacts.Table 4: Global Warming Potential (GWP), Eutrophication Potential (EP), Acidification Potential

(AP) and Primary Energy Use per 1000 kg of eggs in the main egg production

systems in the UK

Erderwärmung (GWP), Eutrophierung (EP), Versäuerung von Böden und Gewässern (AP) sowie Primärenergieverbrauch zur Produktion von 1000 kg Eimasse (Leinonen et al., 2012b).

Feed production and processing was the main component of the global warming potential both in broiler and egg production systems. This was partly affected by the fact that some ingredients, most notably soya and palm oil, were considered to be partly produced on land that has been only recently converted from natural vegetation to agricultural use in South America and South Asia. When calculating the land use change effect on GWP, this study applied the guidelines of the carbon footprinting method PAS2050 (BSI, 2011). However, there is not a full international agreement on the method of how to account for land use changes in LCA, and this has potentially a very big effect on the estimate of the environment impact of broiler and layer feed and poultry production in general.

In addition to the general comparison between different broiler and egg production systems, the modelling framework applied in this study provides an opportunity to carry out detailed farm level assessments on how to reduce the environmental impacts of production. Since the analysis is largely based on functional relationships built in the animal and crop production sub-models, it is possible to examine the overall effects of the expected changes within the system by taking into account all relevant interactions between different production sectors. For example, changes in consumption and composition of feed have effects both on the impacts occurring during the crop production and feed processing, and also on the subsequent emissions from poultry manure during housing, storing and field application. Similarly, the differences in the growth rate of broilers affect the amount of feed consumed per functional unit, the amount of manure produced and the amount of energy and buildings needed, among other things.

Future options for reducing the environmental impacts of animal production include genetic selection for better environmental performance. The current results indicate that improving feed efficiency has potential to reduce the environmental impacts. The modelling framework with functional relationships applied in the present study will allow detailed and realistic tools for quantifying the environmental consequences of future genetic progress in animals. Further options for reducing the high environmental impacts from livestock feed include the use of alternative, more environmentally friendly ingredients.

For example, it can be expected that reducing the inclusion of imported soya, partly originated from recently converted agricultural land, and replacing it using locally grown protein sources may reduce the high greenhouse gas emissions related to both land use changes and long transport distances.

References

BSI (2011): Specification for the assessment of the life cycle greenhouse gas emissions of goods and services. PAS 2050:2011. http://www.bsigroup.com/Standards-and-Publications/How-we-can-help-you/Professional-StandardsService/PAS-2050/ IPCC (2006): IPCC Guidelines for National Greenhouse Gas Inventories. (2006 Guidelines) http://www.ipccnggip.iges.or.jp/public/2006gl/index.html LEINONEN, I., A. G. WILLIAMS, J. WISEMAN, J. GUY and I. KYRIAZAKIS (2012a): Predicting the environmental impacts of chicken systems in the UK through a Life Cycle Assessment: broiler production systems. Poultry Science 91: 8-25.LEINONEN, I., A. G. WILLIAMS, J. WISEMAN, J. GUY and I. KYRIAZAKIS (2012b): Predicting the environmental impacts of chicken systems in the UK through a Life Cycle Assessment: egg production systems. Poultry Science 91: 26-40.

Zusammenfassung

Eine quantitative Analyse der Umweltbelastung durch Broilermast und Produktion von Eiern in verschiedenen Haltungssystemen in Großbritannien

Die Ökobilanz verschiedener Haltungssysteme für die Produktion von Broilerfleisch und Eiern wurde berechnet. Es wurde von typischen Praxisergebnissen in Großbritannien ausgegangen, die in den Tabellen 1 und 2 dargestellt sind. Die Umweltbelastung wurde anhand folgender Kriterien berechnet:

(1) Beitrag zur globalen Erwärmung, (2) Beitrag zur Eutrophierung von Gewässern (EP), (3) Versäuerung von Böden (AP) und (4) Primärenergieverbrauch pro Tonne Broilerfleisch und Eier. Die Ergebnisse in den Tabellen 3 und 4 zeigen erhebliche Unterschiede zwischen den Haltungssystemen in vielen Kriterien der Effizienz, hauptsächlich wegen des unterschiedlich hohen Futteraufwands und der entsprechend höheren Ausscheidung von Kot, aber auch Material- und Energiebedarfs.

Die für diese Untersuchung eingesetzte Methode kombiniert funktionale Beziehungen zwischen verschiedenen Abläufen der Tierhaltung mit mechanistischer Beschreibung biologischer Prozesse und führt im Ergebnis zu einem realistischen und quantitativen Vergleich der Ökobilanz verschiedener Haltungssysteme.

Acknowledgement This research was financially supported by Aviagen Ltd, DSM Nutritional Products Ltd, Harbro Ltd, Moy Park Ltd, National Farmers’ Union, Noble Foods Ltd, O’Kane Poultry Ltd, The Soil Association Ltd and Waitrose Ltd with match funding from Defra, through the Sustainable Livestock Production LINK program, DARDNI and the Scottish Government.

Suscríbete a nuestro Newsletter

Y entérese de todas las novedades del sector.