Introduction

At the time a fertile egg is laid, there is already a small embryo floating on the yolk. The vitality of this embryo must be preserved during storage until the point in time when the incubation process starts. To achieve this, the eggs are handled carefully and temperature fluctuations avoided as much as possible under practical conditions (Barten, 2007). Beside this common practice, specific management procedures may help to minimise the loss of hatchability during extended egg storage. This paper reviews recommendations for handling and storage of hatching eggs from layer breeders, with focus on ideas for prolonged egg storage.Optimal egg storage condition

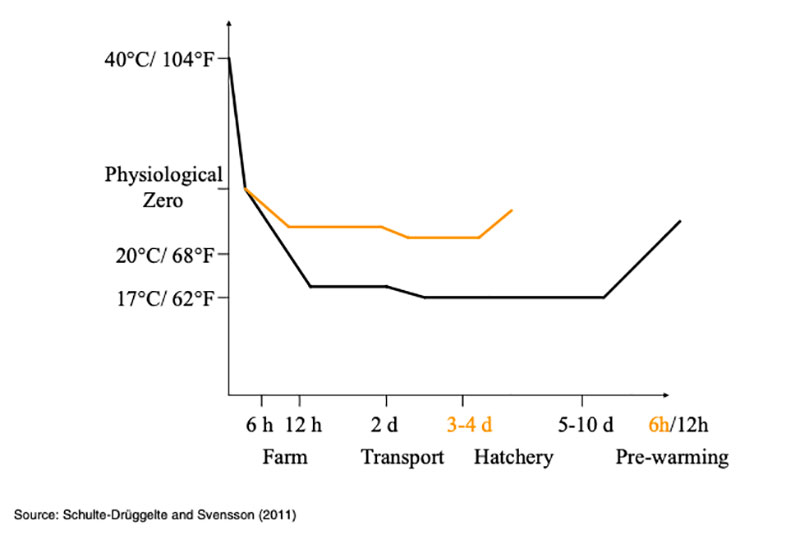

After oviposition the development of the embryo which started in the hen’s body, has to be stopped. Therefore the egg should be cooled down below “physiological zero” (26 – 27 °C) (Funk and Biellier, 1944). This process usually happens inside the nest or on the egg belt. If the ambient temperature is higher (which is not uncommon during summer months), delayed cooling may be a problem. In this case eggs should be collected more frequently to assure that the temperature of the embryo is brought down from 40 °C body temperature to 26-27 °C within six hours. A temperature in the 37-27 °C range leads to unbalanced development and hence early embryonic mortality. Too quick cooling may also weaken the embryo. Further research is needed to determine whether this is due to retarded development or other factors (Schulte-Drüggelte and Svensson, 2011).Figure 1: Optimal development of the egg temperature from oviposition until setting depending

on the storage length

Once the cell division is stopped the egg needs to be further cooled down. This is necessary to control the deterioration of the albumen and necrotic cell deaths. Control means, that there are different optimal egg storage temperatures depending on storage length. Eggs which are set within 4 days of lay don’t need to be kept at a temperature below 20 °C; in this case 21–22 °C is regarded as optimal. This relatively high temperature promotes the thinning of the albumen, which improves the gas exchange during early incubation. On the other hand, it is low enough to maintain the vitality of the embryo. In most layer hatcheries, it is common to store the eggs up to 10 days. For this storage length the recommended temperature is 16 – 18 °C. Temperature ups and downs should be avoided, as they can cause early embryonic mortality (Bramwell, 2008). Ideally the hatching eggs experience only two temperature changes from the moment of lay until pre-warming (see figure 1).

The humidity during storage is not as important as the temperature, as its impact on hatchability is limited (Meijerhof, 2000). When eggs are stored only up to 10 days, 50 – 60 % relative humidity is sufficient. Higher humidity, up to 80 %, is not harmful. Above 80 % relative humidity growth and spread of bacteria and mould is likely to become a problem. Eggs scheduled for long storage benefit from higher humidity to avoid excessive moisture loss of the eggs. The target in this case is 70 – 80 % relative humidity

Ideas for long storage

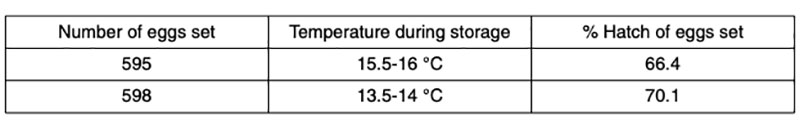

If eggs are scheduled for a long storage period, the hatchery manager can make use of different tools to minimise the negative impact on hatchability. These tools either aim to improve the vitality of the embryo or they support the quality of the egg contents or both (Reijrink, 2010). The temperature during storage can be decreased down to 10-12°C. At lower temperature the water loss of the eggs is reduced and the deterioration of albumen slowed down (Walsh, Rizk and Brake, 1995). Table 1 shows the results of a recent trial with eggs from a grandparent flock stored 16 days at different temperatures.Table 1: Hatchability of eggs from a commercial White Leghorn flock, stored at different

temperatures (source: female line of LSL)

However, a temperature below 15 °C is not recommended for commercial practice. In many situations the extra cooling is not cost-efficient and creates other problems when it comes to setting, like egg sweating or/and a long pre-warming time. Very good hatching egg planning would be required to handle this tool successfully. Egg sweating, i.e. condensation of water on the eggshell, may happen e.g. when cold stored eggs are brought to a warm setter room. Egg sweating must be avoided by any means, because it allows micro-organisms to multiply on the wet surface, penetrate the shell and contaminate the egg. In most cases it helps to limit the temperature difference between cool and warm room to max. 11 °C.

A simple approach to preserve hatchability is to turn the eggs during storage like it is done during incubation. If there is no automatic equipment installed, turning by hand three times each day is sufficient. If the eggs are kept on cardboard trays instead of setter trays, they can be stored upside down – with the pointed end up. This keeps the yolk and the embryo in a central position and protects the latter during storage (Mayes and Takeballi, 1984). Eggs should preferably not be transported this way, because it might cause loose air cells. Of course they should be set in the incubator with the pointed end down. Turning the eggs back up just before pre-warming/setting is early enough.

Pre-storage incubation is another procedure successfully applied in several commercial layer hatcheries. Its mode of action is based on the fact that the developmental stage of the embryo at point of lay is not optimal for long storage. In nature, it would be altered by periodical warming of the eggs during the time the hen sits on the nest to produce the next egg of the clutch. In the hatchery it is possible to achieve similar results by incubating the eggs for a short time soon after lay. This leads to a stage of development where the embryo is less susceptible to cell death during the storage period (Fasenko et al., 2001; Lourens, 2006).

Pre-storage incubation cannot improve, but it can help to maintain hatchability. Therefore it makes sense to use this technique if eggs are scheduled for a storage period which would usually reduce hatchability significantly. This will depend on local conditions and may differ between strains, age of flock and storage conditions.

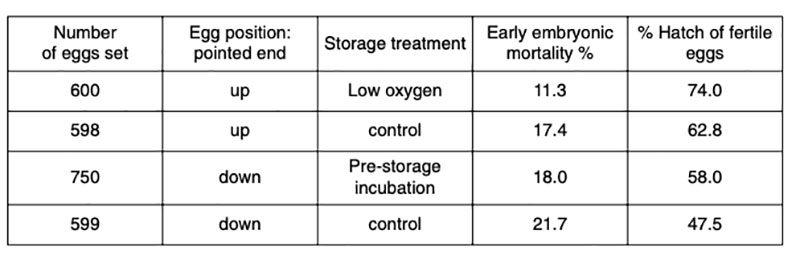

Table 2 shows the results of a recent hatchery trial, where we compared two egg positions during storage in combination and low oxygen and pre-storage incubation against untreated controls. Eggs from a grandparent flock of commercial White Leghorns (LSL) were used and stored for 20 days before incubation. For the low oxygen treatment, the eggs were stored in a gas tight cabinet with nitrogen and 1 % oxygen. Pre-storage incubation was practiced in a single stage setter on day 1 of storage and lasted 6 hours, including 5 hours with an egg temperature between 99 and 100 °F.

Table 2: Average hatch of fertile eggs after 20 days storage at 16°C with different treatments

In this experiment, storing the eggs upside down improved hatch of fertile eggs by 15.3%, pre-storage incubation of eggs stored normally 11.5%, and low oxygen treatment of eggs stored upside down by 11.2%. Assuming that differences between trays can be ignored, these differences are statistically highly significant and of practical interest.

Discussion and conclusions

On a research level many experiments have been made with altered air composition during storage to preserve egg quality (Mayes and Takeballi, 1984; Reijrink, 2010). The results are often promising (including our own results in table 2), but so far none of these techniques have become routine practice in the industry. The main reason is that the technique is complex and costly and would probably only pay back in PS – hatcheries routinely storing the eggs for more then 14 days. More applicable is a low egg storage temperature, the storage of hatching eggs with the pointed end up or pre-storage incubation. If pre-storage incubation is practiced, it should be preferably done with fresh eggs up to two days after lay. In case the eggs have not been properly cooled after oviposition, the effects of pre-storage incubations may be negligible or even negative, because the embryos are already at an advanced stage of development.References

Barten, M. (2007): Poor performance due to transportation! World Poultry Vol. 23 No. 8.Bramwell, K. (2008): On-farm egg storage: Avoid pre-incubation. International Hatchery Practise. Vol.23 No.3.

Fasenko, G.M., V.L. Christensen, M.J. Wineland and J.N. Petite (2001): Examining the Effects of Prestorage Incubation of Turkey Breeder Eggs on Embryonic Development and Hatchability of Eggs Stored for Four or Fourteen Days. Poultry Science 80: 132-138.

Funk, E.M. and H.V. Biellier (1944): The minimum temperature for embryonic development in the domestic fowl (Gallus domesticus). Poultry Science 23: 538-540.

Lourens, S. (2006): Heating eggs before storage increases hatchability. World Poulty. Vol.22 No.4: 22-23.

Mayes, F.J. and M.A. Takeballi (1984): Storage of Eggs of the Fowl (Gallus domesticus) before Incubation. World’s Poultry Science 40: 131-140.

Meijerhof, R. (2000): Moisture loss during storage. World Poultry Special 2000: 8-9.

Reijrink, I. (2010): Storage of hatching eggs – Effects of storage and early incubation conditions on egg characteristics, embryonic development, hatchability and chick quality. Ph.D. Thesis, Wageningen University, The Netherlands.

Schulte-Drüggelte, R. and S. Svensson (2011): Hatchery Management Guide. LTZ.

Walsh, T.J., R.H. Rizk and J. Brake (1995). Effects of storage for 7 or 14 days at two temperatures in the presence or absence of carbon dioxide on albumen characteristics, weight loss and early embryonic mortality of broiler hatching eggs. Poultry Science 74: 1403–1410.

Zusammenfassung

Empfehlungen für die Lagerung von BruteiernUm die Brutfähigkeit von befruchteten Eiern auch bei längerer Lagerung so weit wie möglich zu erhalten, ist darauf zu achten, dass die Eier innerhalb von sechs Stunden nach der Eiablage auf weniger als 26°C und innerhalb von zwölf Stunden auf die anschließende Lagertemperatur von 16- 18°C abkühlen. Die Eier sollten möglichst geringen Temperaturschwankungen ausgesetzt werden. Eine relative Luftfeuchtigkeit von 70-80% ist zu empfehlen.

Zur Verbesserung der Schlupfrate bei längerer Lagerung ist es zusätzlich möglich, die Lagertemperatur von Anfang an niedriger zu wählen (15°C), Eier mit der Spitze nach oben zu lagern oder sie am Anfang der Lagerungszeit vorzubrüten. Versuche, die Luftzusammensetzung während der Lagerung zu verändern, sind vielversprechend, aber diese Verfahren sind noch nicht praxisreif.