Abstract

The use of Dual Purpose Breeds (DPB) is considered a strategy to avoid killing of day-old male chicks of layer lines. Since these males grow slowly and have a poor feed conversion rate, DPB have been developed by commercial breeding companies. Despite better growth rate of DPB males the production cost of these birds will not be covered by sales even if the price is three-fold the price of conventional broilers. The deficit in such a system has to be balanced by an increase of price for eggs from DPB hens of about 2.6 to 3.9 ct. Transition from the conventional system using specialized layer and broiler breeds for egg and meat production to DPB would require synchronization of the placement of male and female chicks. The use of DPB would also increase the requirement for feed, land and water resources.

Keywords

nutrition, poultry, layers, raw materials, DDGS

Introduction

The use of dual purpose breeds was common practice in conventional poultry production until the 1960s. However the genetically determined antagonism between growth rate and reproduction has led to the differentiation of special breeds for meat and egg production (figure 1). While in meat type birds both, males in females are being used, the males of layer lines are killed at day-old and processed as feed for pet and zoo animals. There are ethical and legal reservations against this practice and solutions are thought to solve the problem.

Figure 1: Effect of 60 years selection for meat or egg production on the phenotypic appearance at 35 days of age: Ross 308, Lohmann Dual and Lohmann Brown pullet (male and female) (from left to the right)

However, attempts to grow these males to marketing weight and to sell them as broilers have failed so far because of the height production costs and lack of acceptance by the consumers (Damme 2003, König et al., 2012). The determination of sex in ovo (Krautwald-Junghans et al., 2012) is being investigated at the time. However, it is not clear whether this method can be applied under practical conditions in the future. Another solution is the use of dual purpose breeds (Icken et al., 2013). In this case, males should have acceptable growth rate and slaughter yield, and the females should show a high egg production. Earlier tests with pure lines of traditional dual purpose breeds, like the Australorps, Bielefelder, New Hampshire and Rhode Island Red, have shown that they are not efficient in egg and meat production (Lange K., 1995; Hahn et al., 1995). Commercial breeding companies produced dual pupose breeds (DPB) using crosses of meat and layer lines, such as Lohmann Dual (LD) (Lohmann Tierzucht, Cuxhaven) or Walesby Special (WS) (Hölzl Hatchery), Dominant Red Barred (Dominant) or Novogen Dual (Grimaud Frères, France) using the sex-linked dwarf gen. This major gen reduced the body weight of the females by about 25 % while the males grow at a normal rate. The low body weight of the dwarf hens allows ad libitum feeding of the pullets and layers. In contrast, pullets of normally growing DPH needs to be feed restricted. This increases the risk of feather pecking and cannibalism. Therefore using Dwarf hens for DPB avoid welfare problems related to restricted feeding and beak trimming.

Performance tests have shown that Lohmann Dual (LD) and Walesby Specials (WL) have sufficient performance in meat and egg production (Urselmans et al., 2015). Therefore they have been chosen for the present study.

The objective of this study is to compare the economic aspects of the conventional egg and poultry meat production system using specialized hybrids with DPB.

Basic data and costs for meat production

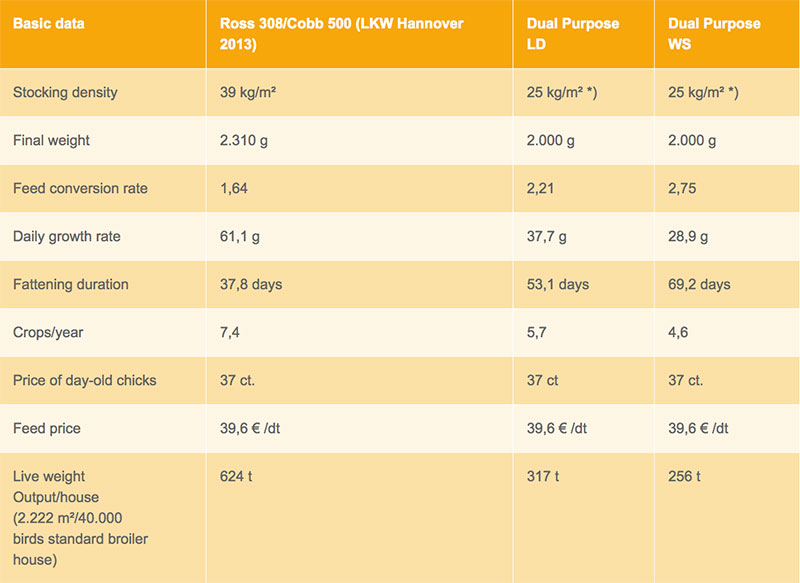

Basic data for the calculation of production costs are received from tests of males of LD and WS in 2013 (Urselmans et al., 2015), and the evaluation of 474 flocks of Ross 308 and Cobb 500 on commercial broiler farms in Lower Saxonia, Germany, in 2013 (Schierhold, 2014). Details of the experimental conditions are shown in table 1. For the economic comparison the following management conditions are applied. DPB breeds are usually kept under low stocking density (25 kg/m²) while the standard density for the conventional heavy broilers (> 1,6 kg) in Germany is 39 kg/m². The low stocking density of 25 kg/m² is required when these birds are to be sold as premium or “label” broilers.

Table 1: Basic data for conventional broilers (average of results received from commercial broiler farms collected by the Agricultural Chamber of Hannover, Lower Saxonia, Germany in 2013 and of two Dual purpose breeds (Lohmann Dual, LD, Walesby Special, WS).

*) The lower stocking density for DPB was due to the intention to sell the birds as premium broilers

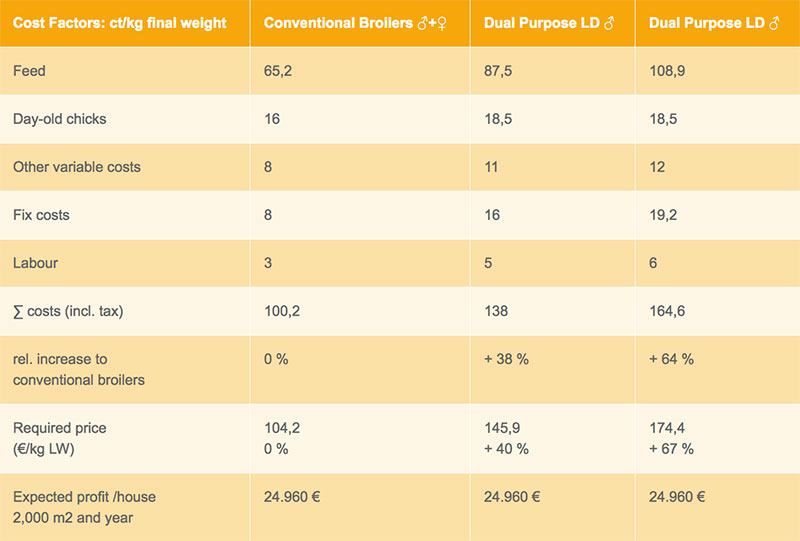

Costs for feed and day-old chicks where calculated on the basis of 2013. A price of 37 cent was set for day-old chicks of all breeds. This appears to be too high for the DPB. However we have to consider that these birds are raised to a higher age than conventional broilers and therefore require vaccination against Marek’s disease. In addition 50% of the cost for sexing, which have been attributed to DPB, increases the price for DPB male chicks. Extended fattening time and poor feed conversion of DPB are important cost factors which increase both variable and fixed costs. The production costs are shown in detail in table 2. The difference between DPB versus conventional broilers is 38% (DL) and 64% (WL) respectively. The higher costs of DPB need to be compensated by a higher price.

Table 2: Production costs and required increase in sales price for two Dual Purpose Breeds (Lohmann Dual, LD, and Walesby Special, WS) to achieve equal profit as in conventional broilers (Ross 308; Cobb 500)

Profit in poultry meat production, highly depends on life weight produced per square meter usable space. In a broiler house for 40,000 birds the total life weight production under conventional conditions is about 624 metric tons per year. Assuming a profit of four cents per kilogram, which corresponds to the average profit over 10 years in Germany, the annual profit is €24,960. In order to generate a similar profit in the same house using dual purpose breeds a further increase of the price per kilogram life weight of 7.9 and 9.8 cents/kg is required for LD and WS respectively. The relative increase is 40% and 67% for LD and WS respectively. The difference in price for meat of DPB and conventional broilers will further increase on the consumer level. At a standard weight of 2 kg live weight the slaughter yield of DPB is 2 to 4 % lower than that of conventional broilers. In addition the percentage of breast meat as the most valuable part of the carcass is lower in DPB than in conventional broilers.

Basic data and costs for egg production

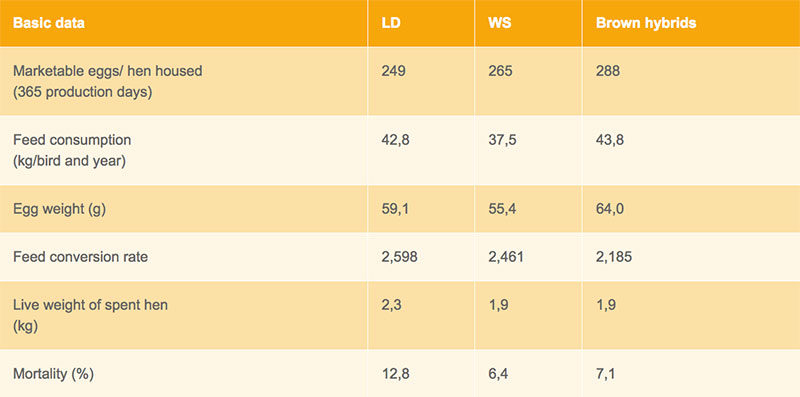

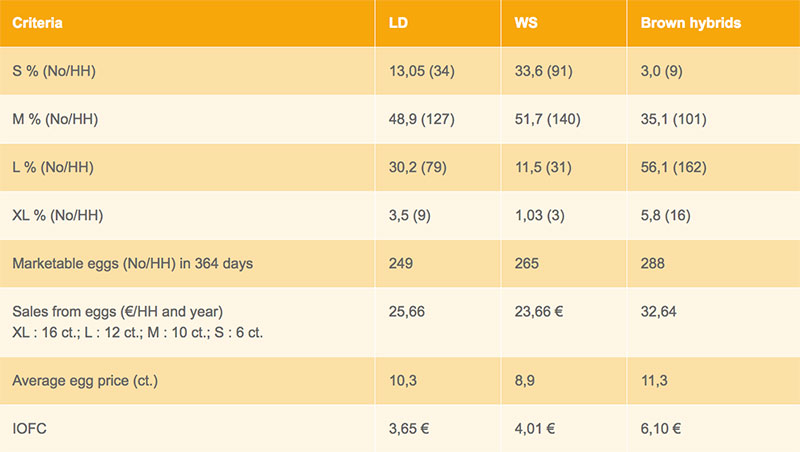

The performance data for the calculation of egg production for commercial layers stem from random sample tests of two state test stations in Germany: Kitzingen, Bavaria, and Haus Düsse, Nordrhein-Westfalen (table 3). Results of 3 brown egg layer strains (Lohmann Brown, Novogen Brown, Bovans Brown) were pooled over both test stations and compared with the two DPB. None of the flocks were beak trimmed. LD laid 249 and WS 265 marketable eggs. DPB not only laid a fewer number of eggs, but also showed a lower egg weight. The percentage of small eggs was 13.1 and 33.6 % for LD and WS respectively (table 4). These eggs are difficult to sell as table eggs. Hence a large part of these eggs are sold at low price to egg processing plants. The low egg weight of DPB is due to the low body weight. Breeders of DPB use the sex-linked Dwarf gen. Economic estimations of DPB and conventional brown egg shell layers are presented in table 4. Sales over feed costs were considerably lower in both DPB as compared to conventional breeds: 2.45 € and 2.09 € for LD and WS respectively. This difference does not include the risk of small eggs to be sold to processing plants. Considering the share of marketable eggs and the prices for the different weight classes (16, 14,12 and 6 cts for XL, L, M und S) the income from egg sales is 25.66, 23.66, 32,64 for LD, WS and conventional hybrids respectively.

Table 3: Basic data of two Dual Purpose Breeds (Lohmann Dual, LD and Walesby Special, WS) and pooled results of commercial brown shell layer strains

Table 4: Result of egg grading (percentage of small, S, medium, M, large, L, and extra large eggs, XL and egg number/ hen housed, HH, in the different categories), income from sold eggs und and income over feed cost, IOFC, of two Dual Purpose Breeds (Lohmann Dual, LD and Walesby Special, WS) and pooled results of commercial brown layer strains

Calculation of IOFC: (Egg mass (kg) *1,0 € – Feed Consumption (kg)* 0,3€)

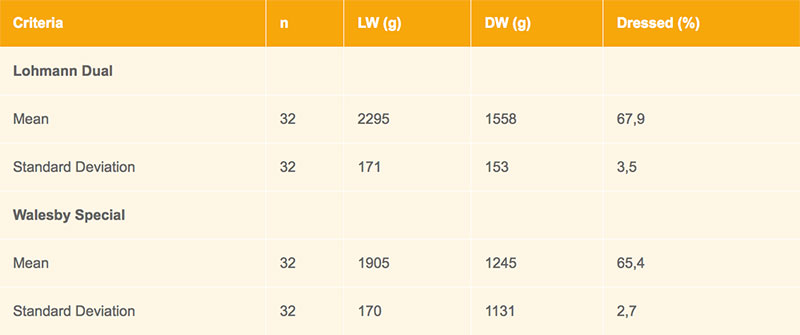

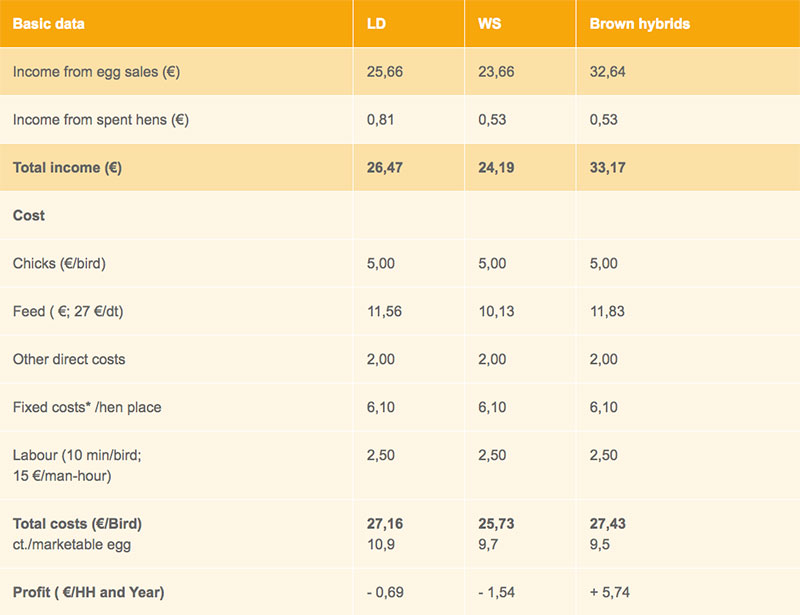

Spent hens of DPB are usually heavier than conventional layers and have a larger breast muscle (table 5; figure 2). Therefore they might be sold for a higher price. In the present study the live weight of LD was 2.3 kg, while WS had the same weight as the conventional layers. For the calculation of the egg production costs we used the same price of day-old chicks, other direct costs, labour and fixed costs for both DPB and conventional lines.

Table 5: Live weight (LW) and dressed weight (DW) of two Dual Purpose Breeds (Lohmann Dual, LD and Walesby Special, WS)

* Fixed costs: total 70 € /hen place; 45 € building, 25 € equipment; depreciation building 4%; depreciation equipment 10%; interest rate 3%/2; 1% for maintenance, repairs and miscellaneous

Figure 2: Dressed Dual Purpose hens: Walesbury Special (left) and Lohmann Dual (right) after 12 month laying period

Conventional breeds and DPB differed only in sales of eggs, spent hens and feed costs. The profit per hen housed and year was 5.74 € for the conventional layers. LD and WS produced losses of -0.69 € and – 1.54 € (table 6). The difference in sales per hen housed for eggs and spent hens of conventional layers and DPB was – 6.34 and – 7.28 € for LD and WS.

Table 6: Calculation of costs, income and profit in the egg production part of two Dual Purpose Breeds (Lohmann Dual, LD and Walesby Special, WS) and commercial brown layer hybrids.

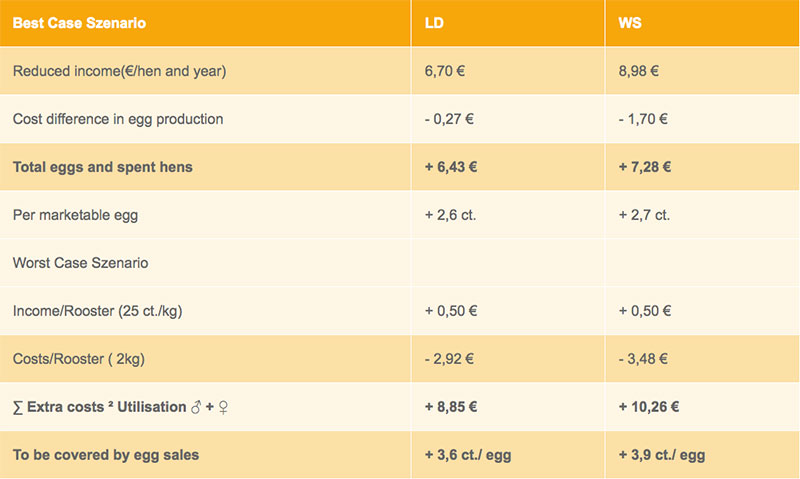

For the joint calculation of the economic result of egg producing females and meat producing males we assumed two scenarios. For the best case we assumed that all males could be sold as premium broilers at a price 40 to 70 % higher than conventional broilers (93 ct/kg LW without tax). In order to achieve the same economic result as in the use of conventional broilers and layers the price for eggs of DPB has to be 2.6 to 2.7 cts higher than the price which can be achieved on the egg market at present. In the worst case scenario there is no market for the males for human consumption (for their poor carcass conformation and lack of tenderness) and they have to be sold like spent hens. In this case the difference between production costs and income from sales is 2.42 and 2.98 €/bird for the LD and WS respectively. For the system to be economically viable the difference has to be compensated by an increase in egg sales of 3.6 and 3.9 cts per egg in the LD and WS lines (table 6 and 7).

Table 7: Required extra price for eggs from two Dual Purpose Breeds (Lohmann Dual, LD and Walesby Special, WS) under different marketing scenarios for the males

Best Case Szenario: all males sold as premium broilers with higher price (1,46 €/kg to 1,74 €/kg LW) Worst Case Szenario: all males sold for pet food like spent hens (0,5 €/kg LW)

It has to be considered that the above calculations are based on the present dual purpose breeds, conventional management and current prices for eggs and poultry meat. It may be possible that other dual purpose breeds are being developed and changes in the market situation improve the economic situation of DPB. The situation may also be different in organic production systems. This is being investigated at present at the University of Weihenstephan, Freising, Bavaria.

Conclusions

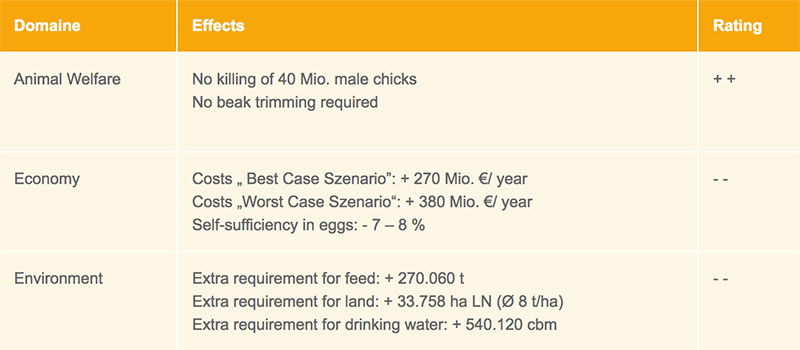

The main aspects of the conclusions are summarized in table 8. Killing of male day-old chicks of layer lines could be avoided when Dual Purpose Breeds instead of specialized egg-type lines are being used for egg production. A precondition for this is the synchronization of housing the female chicks to the pullet rearing farms and male chicks to the broiler farms. Using houses of the same size of chicken houses for DPB as for specialized breeds, the total egg production would drop by 30 eggs per hen housed. The self-sufficiency rate for eggs in Germany would be reduced by 7 to 8 %. In order to replace this amount of eggs through imports, about 4 Mio. female day-old chicks would be required and the same amount of males would be killed in the exporting country where this procedure is not prohibited.The extra costs of raising DPB males to slaughter age would be 270 to 380 Mio. €/ year. These costs have to be compensated by higher egg prices (2,6 to 3,9 cts/egg). With regard to the high level of income in Germany, animal welfarists consider this increase of egg price not as relevant. However, the change towards DPB would also have serious environmental implications for the higher requirement of resources:

270.000 metric tons of extra feed

33.758 ha of extra arable land

540.000 m³ of extra drinking water

Considering the worldwide shortage of these resources required for human nutrition, the use of DPB would also represent a huge ethical dilemma (table 8).

Table 8: Impact of the use of Dual Purpose Breeds as alternative of killing male chicks of specialized layer breeds at day-old in regard to animal welfare, economical and environmental aspects in Germany

40 Mio. ♂ x 2 kg Live weight x 0,84 kg (Ø feed conversion rate worse than Ross 308 or Cobb 500) = + 67.200 t extra feed; 40 Mio. ♀ x 14,7 kg egg mass x 0,345 Ø worse feed conversion rate than brown layer hybrids = + 202.860 t extra feed;

Acknowledgement

The authors thank Werner Bessei for the translation of the article.References

Damme K. (2003): Fattening performance, meat yield and economic aspects of meat and layer type hybrids. World`s Poultry Science Journal, 59, March, 50-53.Damme K., Urselmans S., Simon J., Stegemann J. (2014): 2. Herkunftsvergleich von Legehybriden in Boden- und Kleingruppenhaltung. In: Geflügeljahrbuch 2015, 117-122 Eugen Ulmer KG, Stuttgart, ISBN 978-3-8001-8256-5.

Hahn G., Deerberg F., Lange K. (1995): Mit Rassegeflügel Fleisch erzeugen? DGS MAGAZIN 22, 37-40.

Icken W., Schmutz M., Cavero D., Preisinger R. (2013): Dual Purpose Chicken : The Breeder`s answer to he culling of day old male layers. Proc. IXth European Symposium of Poultry Welfare, Uppsala, Schweden, 91.

König M., Hahn G., Damme K., Schmutz M., (2012): Utilization of laying type cockerels as cocquelets – influence of genotype and diet characteristics on growth performance and carcass composition. Arch.Geflügelk. Vol 76 (3), 197-202.

Krautwald-Junghanns M., Bartels T., Burkhardt A., Cramer K., Einspanier A., Fischer B., Förster A., Koch E., Popp J., Preisinger R., Steiner G., Sydow R., Weber K., Weißmann A. (2012): Mögliche Alternativen zur Tötung männlicher Eintagesküken aus Legehennen – zum Stand eines interdisziplinären BLE Forschungsprojekts. DGS MAGAZIN 35, 25-29.

Lange K. (1995): Legeleistungsprüfung für Rassegeflügel – Was leisten die alten Rassen. DGS MAGAZIN 35, 41-45.

Urselmans S., Damme K., Schmidt E. (2015): Leistungsprüfung von Zweinutzungshühnern- die Tiere sind kompakt und ruhig. DGS MAGAZIN 1, 33-37.