Abstract

The global production of duck meat was roughly 4.3 million tons in 2012. It represents a valuable source for human consumption especially in Asian countries. Most of this duck meat is produced by growing Pekin Ducks. To improve the efficiency of this business, breeding companies have been selecting for superior performance in all traits of economic importance. Selection is focused on daily gain, meatiness and feed efficiency of broiler ducks, without neglecting the number of ducklings per female housed. Using more precise data recording tools, as for instance RFID based data recording and more powerful IT technology to estimate genetic parameters and breeding values, the performance has been much improved over the last 20 years.

Keywords

Pekin Ducks, performance testing, genetic parameters, breeding value estimation, breeding

Introduction

The production of duck meat increased remarkably during the last 20 years, up to about 4.3 million tons in 2012. The main producer is China, producing more than 80% of all worldwide duck meat (FAOSTAT, 2015). According to information of Guémené et al. (2011) roughly 90% of it is based on fattened Pekin Ducks. Only 4% of is produced by Muscovy Ducks and 6% of it is available as a by-product from Mule Ducks, used for the fatty liver production.Ducks have been very popular in Asia since historical times and they remain popular until today. The Chinese not only like the high nutritive value and tastiness of the duck meat, but also utilise their feet, tongues and other by-products for human consumption and appreciate the high quality of the feathers. The duck varieties, especially the Pekin Ducks, are very robust and can be kept under various climatic conditions, often in very simple housing.

Several breeding companies are selecting ducks for meat production. Although most of them are based outside of Asia, their market share in Asian countries is high and their breeding work has to consider market demands in Asia. This paper will focus on the selection of Pekin Ducks for meat production.

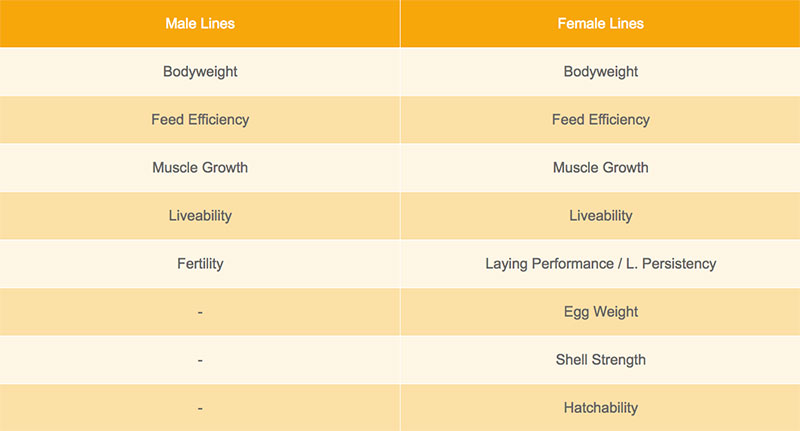

Table1: Selection traits of meat type Pekin Ducks

Fig. 1: For regular recording of body weight the ducks are placed in a special funnel fitted on a digital scale

Relevant traits and performance testing

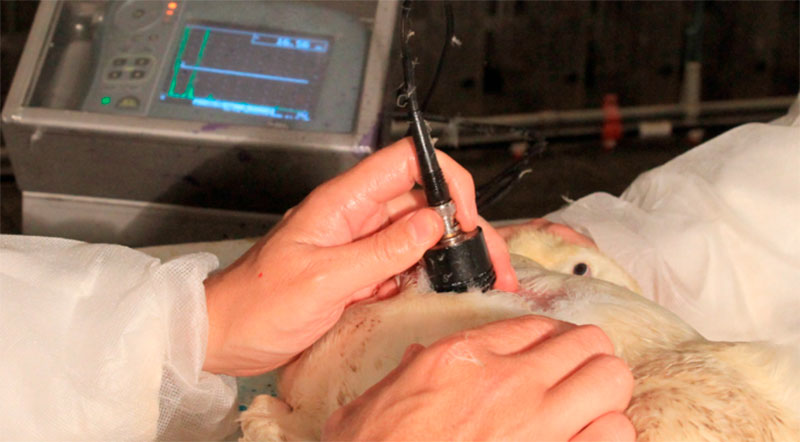

Similar to meat type chicken breeding programs, Pekin Ducks are selected in specialized male and female lines, which are combined at the grandparent and parent level to produce commercial broiler ducks. In the male lines, the main focus of selection is on growth rate, feed efficiency, carcass yield and meat quality, while the female lines are also selected for egg production and hatchability.At 40 to 45 days, the broiler performance of all progeny of all pure lines and their crossbred offspring are tested. Increasing the daily gain and reducing the slaughter age at the same time, was, like in meat type chicken, the main tool to accelerate the production efficiency. When processing ducks with a genetically extended growing capacity at a younger age the feed efficiency will be improved (Klemm, 1985). Those more juvenile ducks have less breast meat and less fat compared to the more matured ones. They used less nutrients and feed to form their body and have a characteristically different growing curve and “physiological age” compared to their early maturing counterparts. To improve or at least to maintain the meatiness of ducks, while selecting on feed efficiency, the focus has to be set on meat quality as well. At least the time for testing the bodyweight of pure line birds and crossbred progeny has to be adjusted to that younger age. In the ORVIA breeding program all birds are additionally graded to judge the carcass quality via the conformation. The depth of the breast muscle is precisely detected by using an ultrasonic device. Cup-up tests where full sibs or half sibs are slaughtered to record the total body composition would bring additional information but are always combined with a complete loss of valuable pure line birds. The data recorded by the selection crews are incorporated directly into the data bases. Since this is done very precisely with modern recording devices, the data are immediately available for parameter and breeding value estimation.

Fig. 2: Breast Thickness is measured using ultrasonic technique

Improvement of feed efficiency by selection

Feed efficiency has become more and more important for all kinds of animal production, in response to rising feed cost and awareness of limited resources and environmental issues. Therefore, individual feed intake of the birds is measured and used in selection programs. In the past, individual feed intake of meat type poultry has been recorded in single cage systems, (Thiele, 1995), but this system is unfavourable for the ducks and may not reflect feeding behaviour under commercial floor conditions. The modern RFID technology enables the breeding companies nowadays to record even small meals of individuals under nearly practical housing conditions. In these testing units not only the amount of feed consumed can be recorded, it opens the possibility to observe also the feeding behaviour of the ducks, with the frequency of meals and the size of a single meal (Bley, 2003; Howie et al. 2009). The availability and utilisation of these “feeding stations” accelerates the genetic progress in feed efficiency. Companies which invested in this technology already several years ago gained a huge advantage, while further developing their pure line breeding stock. Records of daily feed intake can be used to improve feed efficiency in combination with weight gain during the testing period as the commonly known FCR or, independent from metabolic body weight and weight gain, as Residual Feed Intake (RFI) (Aggrey et al., 2010; Herd and Arthur, 2009):

Fig. 4 & 5: Feeding Station to measure individual feed intake in free moving flocks. Left: Entrance of the feeder station is designed so that only one duck has access to the feeder. Ducks in the feeding station are identified using RFID technique. Right: Feed hoppers are fitted to electronic scales. Feed consumption is being recorded and stored on a PC.

The laying performance is usually tested over a period of 35 production weeks. Traditionally laying birds are kept in single cage systems. ORVIA is developing a fully automatic nest system to replace single cages in future. With the new nests the laying performance can be recorded in floor pens. During the testing period, time wise information about egg weight, shell strength, fertility and hatchability are recorded. Sperm quality is analysed before males are used for pedigree reproduction. For testing the fertility and hatchability of females, the use of pooled sperm is preferred.

Fig. 5 & 6: Testing Egg Production in Single Cages:

Right: single cages with nests

Left: Identification of individual hatching eggs is essential for pedigree reproduction

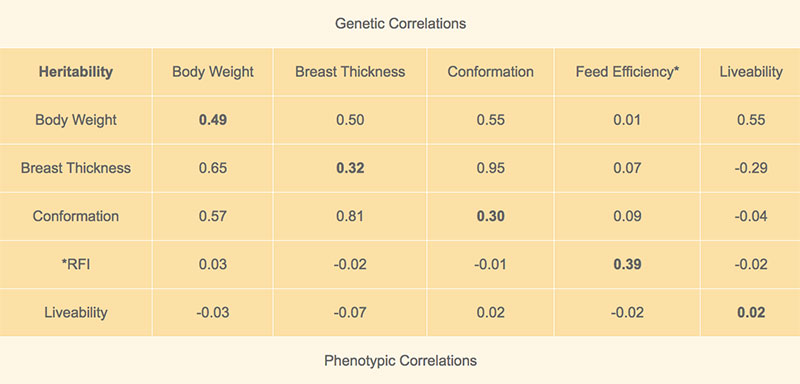

Estimates of heritabilities and correlations among traits are summarized in table 3. All selection criteria except liveability have a sufficiently high heritability to predict further improvement. Residual feed intake is (by definition) independent from body weight and a useful parameter to judge the conversion of feed to body mass. As in other poultry species, liveability has also limited genetic variation in Pekin Ducks and will be a preferential candidate for genomic selection.

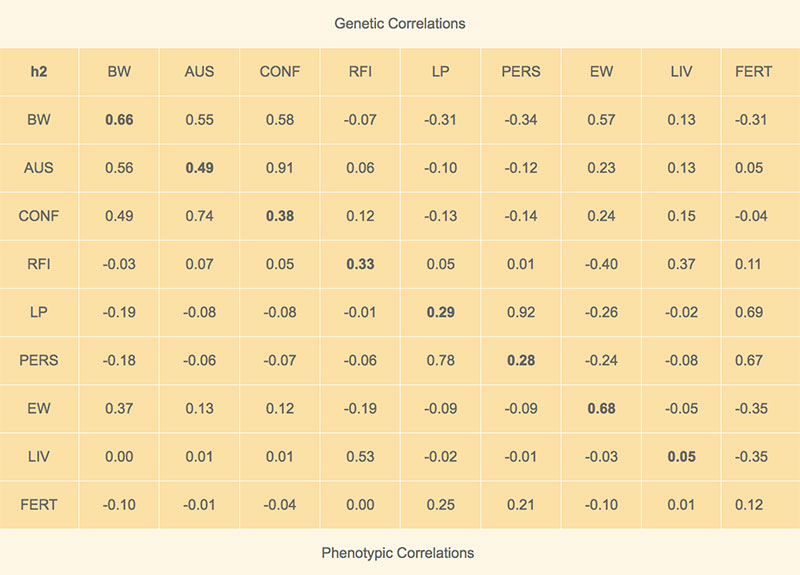

With the exception of egg weight and shell density, the reproductive traits have a lower heritability compared to the broiler performance traits, but sufficient variation to make future progress possible.

Table 2: Heritabilities (bold figures on the diagonal), genetic and phenotypic correlations between parameters of broiler performance traits (Male line ORVIA breeding program; n=16900)

*Residual Feed Intake

Table 3: Heritability (bold figures on the diagonal), genetic and phenotypic correlations of growth and laying performance traits (Female line ORVIA breeding program; n=20220)

BW=Body Weight; AUS=Breast Thickness; CONF=Conformation; RFI=Residual Feed Intake; LB=Laying Performance; PERS=Persistency; EW=Egg Weight; LIV=Liveability FERT=Fertility

Estimation of genetic parameters and breeding values

In these days very powerful IT technology and software tools are available which enable the geneticists to estimate the breeding values. A quick and precise data recording combined with those possibilities enables the specialists to select the progeny of each pure line. Based on linespecific indices, the quality of males and females is judged to select and mate ducks for the next pure line pedigree generation. All economically relevant traits have to be combined in such a way, that the strategic importance of each line and its position in the crossbreeding program is taken into consideration. The main target is to improve the performance of the final product, while maintaining or improving the performance in the parent stock as well.Results

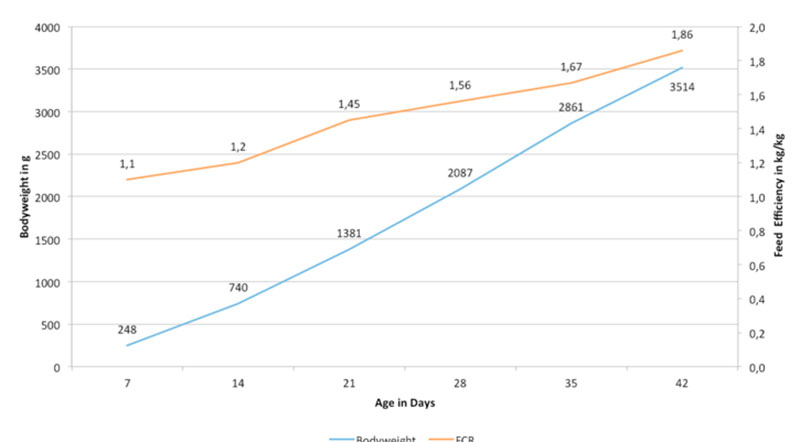

The parent performance of the heavy package is around 230 to 240 ducklings in 52 weeks of production. Heavy hybrids have an outstanding broiler performance. They grow in 6 weeks of age to a bodyweight of 3300-3500 g. Depending on the nutrient density of the supplied feed; the feed conversion is below 2 kg feed per kg bodyweight. Concerning meat quality, those broiler ducks produce 32-35% of muscles (skin included) of their live bodyweight and have at slaughter 72-75% yield.The annual selection progress for heavy packages can be predicted with 50-70 g higher bodyweight at 6 weeks, 30-50 g less feed for 1 kg gain and about 1 more egg per parent.

Pekin Ducks contribute substantially to the production of food for human consumption, especially in Asian countries. The breeding activities can enhance the effectiveness of that special part of poultry production. Comparable to other poultry species the genetics are concentrated in only a few but highly specialised companies. Duck specific performance testing and breeding value estimation is done with sophisticated tools and will be constantly further developed. Genetic progress will continue in all economically important traits.

Fig.7: Body weight development of ST5 Heavy from 7 to 42 days of age – Field Test Indonesia (Source: ORVIA 2014)

Acknowledgement

The author is working for the company GOURMAUD SELECTION (Group ORVIA) since 2002 as a consultant geneticist.Pictures to illustrate data collection were kindly contributed by the Group ORVIA, the leading French duck breeding company.

References

Aggrey S.E., A.S. Karnuah, S. Bram and N.B. Anthony (2010) Genetic properties of feed efficiency parameters in meat-type chickens Genetics Selection Evolution 42:25Bley, T.A.G. (2003) Untersuchungen zur Variation und Rhythmik der individuellen Futteraufnahme bei Pekingenten in Gruppenhaltung. Ph.D. Thesis, University of Stuttgart-Hohenheim.

Guémené D., Z.D. Shi and G. Guy (2011) Waterfowl production and housing systems worldwide. 30th Poultry Science Symposium, Alternative Systems for Poultry – Health, Welfare & Productivity. Glasgow

Herd, R.M. and P.F. Arthur (2008) Physiological basis for residual feed intake. Journal of Animal Science 87: 64-71.

Howie, J.A., B.J. Tolkamp, S. Avendano and I. Kyriazakis (2009) The structure of feeding behavior in commercial broiler lines selected for different growth rates. Poultry Science 88:1143–1150.

Klemm, R. (1985) Ergebnisse und Auswirkungen einer direkten Selektion auf individuellen Futteraufwand bei Enten. Ph.D. Thesis, University of Leipzig

Thiele, H.-H. (1995) Recent tendencies in Duck Breeding, Proceedings 10th European Symposium on Waterfowl: 421-428