Abstract

As a relatively young branch of agriculture, ostrich farming still requires substantial research concerning farming and especially feeding methods. A study conducted by “artgerecht e.V”, the German Association of professional ostrich farmers as well as its sister association Bundesverband Deutscher Straußenzüchter compared the production costs and meat yield of different management and feeding systems: On the one hand intensive “fattening” of large numbers of birds on limited open space with a strong tendency to indoor keeping for most part of the year, on the other hand an all-year- extensive outdoor browsing with only moderate supplementary feeding. The results show without any doubt that only an ecological and extensive system of ostrich farming can lead to economic success: Competitive product prices mostly depend on costs of production, and low cost can only be reached by making best use of the ostriches’ extraordinary utilization of fiber-rich feedstuffs. Further, since customers today show increasing interest in animal welfare and ask for respective products and quality labels, an ecological farming system will increase the acceptance by the consumer and will ultimately ensure the success of the business. International developments within the ostrich branch confirm the study’s conclusions: Ostrich farms in arid regions as well farms using intensive feeding in areas with lush vegetation either struggle for economic survival or have disappeared altogether.

Keywords

ostrich, production, ecological

Introduction

Many differing, even contradictory methods of keeping and raising ostriches are being practised and propagated on farms around the globe. In South Africa the majority of ostriches is kept on steppe soil or semi deserts with poor vegetation and is fed with farm grown products or with commercially produced feed. „Browsing” is seldom possible and does not play a role in the farmers’ business calculations.In Southern Europe, Turkey or Greece as well as in all eastern European countries large numbers of birds are kept on very limited space – even in shelters heated in winter nights or for several months – and fed almost exclusively with commercially produced feed. Pasture here also hardly plays a role. The same applies to the ambitious new farming nations such as Iran, Pakistan or the People’s Republic of China.

In central Europe, however, professional farms make use of the ostrich’s extremely high capacity to digest fiber and to convert it into growth: They keep their birds on large pastures all year and supplement at maximum 1/3rd of the daily feed consumption with a farm-specific mixture or with commercially produced ostrich feed. But the available grassland for such ecological ostrich farming is scarce in all member states of the European Union as well as in Switzerland, therefore these farms still are the minority. However, the new standards issued by the German Department of Agriculture from now on ask for doubling of available space as well as for smaller group sizes.Thus, only farms with ample space will be able to operate economically in the future.

There are many different systems of farming and different views of adequate and economical feeding – and just as many differing reports of the expenditures for producing a slaughter bird. While the traditional ostrich producing countries in Africa, further Australia and a few European and American farms are able to bring up a slaughter birds for approximately € 250,00, businesses applying the intensive method for instance estimate just feed costs at € 300,00 per bird or even more.

High feed costs as well as high investment and operating costs for instance for expensive sturdy shelters have had a more than detrimental effect on the profit situation of these enterprises. Even in times when the leading ostrich producing country South Africa was banned from the European market, farms working with the intensive system reached no or only low margins.

The same applies to numerous farms in South Africa and Namibia, where commercial ostrich production during the last 15 years suffered from drastic losses or – in the case of Namibia – had to be suspended completely. The reasons are on the one hand long-lasting export bans following outbreaks of Avian Influenza but on the other hand high feed costs, which through lack of cheap forage made a competitive ostrich production impossible.

Even in the warmer regions of Europe ostrich farming has changed fundamentally. During the BSE crisis, when ostrich meat was sought after as a replacement of beef, the branch experienced an extraordinary boom. However, when the panic faded away, customers returned to beef, prices for ostrich meat dropped – often because neither supply nor quality lived up to the requirements of the market.

Diminishing returns on the one hand and high feed costs because of limited space and aridity on the other hand have led to an almost complete disappearance of ostrich farming in countries such as Italy or Spain.In 2000 Italy and Spain counted 4000 ostrich farms. Today only a handful is left in each country – more or less struggling at the edge of subsistence.

The described developments have caused a fundamental shift of importance of ostrich producing nations internationally: In the 20th century southern African countries were considered world leaders – today they hardly play a role. Even South Africa is clearly cut off compared to the actual leading producers.

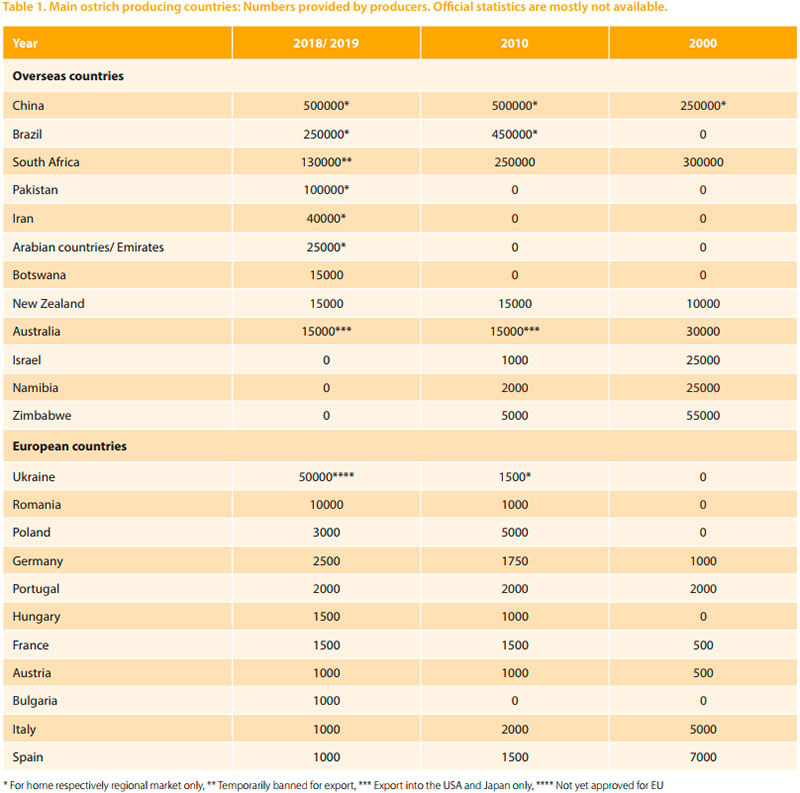

The actual list of ostrich producing nations (Table 1) can only be a snapshot. Further shifts are to be expected, since the high feed costs in intensive systems threaten farms in all parts of the world. At present, producers in Pakistan, Saudi Arabia, the Emirates or Iran still achieve remarkable meat prices. However, their population numbers rise, and consequently a rise in feed costs and therefore in production costs is to be expected. Economic success will thus be reserved to the ostrich farmer who is able to use extensive pasture system – which will hardly be possible in the predominantly arid desert regions, for instance, in Iran (Figure 1a,b,c).

A critical analysis of the necessary expenditures for the production of birds for slaughter is more important than ever – and a helpful tool for present and future farm businesses. The following study aims at comparing costs and returns of different farming and feeding systems and at analysing the effects of the different systems on product quality as well as on consumer acceptance.

Methods

Between 2001 and 2015 a total of 463 birds for slaughter were monitored on six ostrich farms in Germany (Baden- Württemberg, Rheinland-Pfalz, Hessen, Brandenburg) and Poland (Region Gdansk). Two of these farms (group A) applied the extensive system, two (group B) the semi-intensive and (group C) the intensive system. All birds were Zimbabwe Blue or a similarly sized crossbreed. The study looks at production costs, at meat yield as well as at the acceptance of the different farming systems on the side of the customers.Farming systems

Group A was raised under extensive farming conditions from day one to slaughter age. Up to the age of three months group size was 30 birds on green paddocks of 1000 to 3000 m². From the fourth month 15 birds were kept in paddocks of 5000 m². From day 4 onwards, all birds had access to pasture, starting at 20 minutes per day up to unlimited access (day 15 onwards). Up to the end of month 4 all birds were sheltered at night to protect them from predators. Starting at month five, the shelters remained open day and night, even during rain, snow and temperatures below freezing-point. Only chicks up to day five had a heated shelter. From day six to the end of week eight, heating was reduced to local floor heating (pads or water beds for piglets) at the spot where the chicks congregated for rest and sleep. Additional heating lamps from above were optional. After week 9 heating was no longer used, not even during periods of frost. The lowest outside temperature during the winter of 2010/2011 was -22,3 degrees Celsius.Groups B and C were raised under extensive conditions until the birds were four weeks old. They were then moved to contracted farms and raised there semi-extensively and intensively up to slaughtering. Group size on farms B was 30 to 50 birds on paddocks of 2000 m² to 7000 m², depending on age. Farms in group C raised 10 to 12 birds on paddocks of appr. 600 m². A total of 127 group A birds were tested, 198 group B birds and 138 birds from group C.

Feeding

The main feed component of group A was browsing on pasture offering a variety of grasses, clovers and herbs (horse mixture plus white clover). This was supplemented by a ration consisting of maize, barley, wheat and wheat bran, soybean meal, sugar-beet pulp and a vitamin/mineral-premix, prepared fresh every day on the farm. The daily amount varied from 10 g to 1kg per bird, depending on age. The average daily ration of this supplement feed was 825 g from day 3 to slaughter. From October until mid April each group had an ad libitum supply of silage or chopped hay (particle length 2 cm to 5 cm).Because of the high bird density and consequent lack of vegetation, the total intake of group B consisted of silage (58%) and the mentioned farm mixture of grains (42%). The complete ration had been composed and calculated by the feed company producing the premix, but it was frequently altered by the farmer – since he did not have all necessary components permanently available. The daily feed supply per bird was not determined by a set plan but by the farmer’s decision. It ranged from 1100 g to 5000 g depending on age – on average 3800 g per bird and day from month three up to slaughter.

Group C was exclusively fed with pelleted feed produced from the farmers’ own products. The daily supply ranged from 1.030 g to 3000 g depending on age and averaged 2.620 g of pellets and 1 kg of hay.

Costs of feed and pasture

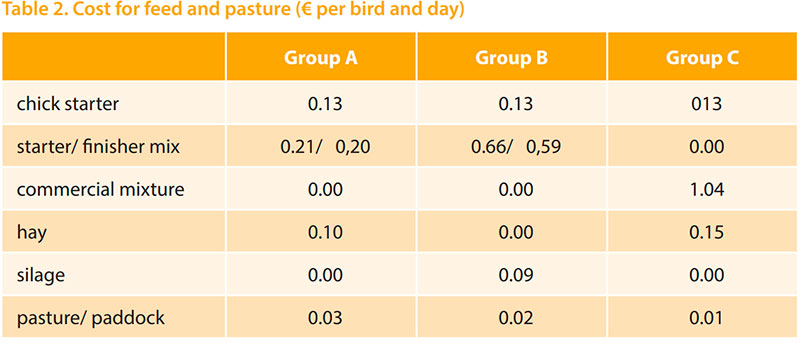

The annual costs of pasture (land) were calculated at € 300.00 per hectare. This amounts to € 12.00 per bird in group A (25 animals/ha on average).- Group B: 40 animals/ha, i.e. costs of € 7.70 per bird

- Group C: 150 animals/ha, i.e. costs of € 2.00 per bird.

Feed consumption in group B amounted to an average of 0.311 kg chick feed per day in 61 days (total: 19 kg), 2.8 kg of grower mix and 1 kg silage in 91 days (total: 593.6 kg plus 212 kg) and 2.8 kg of finisher mix and 1kg silage in 91 days (total: 254.8 kg plus 91 kg).

Feed consumption in group C amounted to a daily average of 0.311 kg of chick starter in 61 days (total: 19 kg) as well as to a daily average of pelleted prefabricated feed of 2.6 kg in 303 days (total: 787.8 kg) plus 1 kg of hay =303 kg).

Group B had very limited possibility to browse, and group C practically none, since the high density of animals left no chance for any vegetation growth.

- The price of chick starter was € 0.41 per kg.

- The price of group A’s grower mix was € 0.25 per kg, finisher mix € 0.24.

- The price of group B’s grower mix was € 0.22 per kg, finisher mix € 0.21.

- The price of group C’s pellets was € 0.40 per kg.

- The cost of hay was € 25 per bale of 500 kg, which amounts to € 0.05 per kg.

- The cost of silage was € 15.00 per bale of 500 kg, which amounts to € 0.03 per kg.

Slaughtering/ Classification of muscles

All birds were slaughtered at the age of +/- 364 days.All prime cuts were evaluated, following the standard muscle classification as depicted in the International Meat Buyer’s Guide Catalogue, Second Edition (published by Animal Technologies CC, Elsenburg 7607, South Africa):

Fillet: Fan Fillet (OS 1046), Eye Fillet (OS 1050), Tournedos (OS 1059), Oyster Fillet (OS 1045), Long Fillet (OS 1060F), Tenderloin (OS 1047)

Steak: Rumpsteak (OS 1035), Triangle Steak (OS 1036), Small Steak (OS 1037), Tender Steak (OS 1038), Moon Steak (OS 1041), Minute Steak (OS 1042), Long Steak (OS 1060S), Small Drum (OS 1014)

Drum: Drum Steak (OS 1011), Flat Drum (OS 1012), Big Drum (OS 1013)

Meat Quality

Altogether 186 persons engaged in five different meat tastings to look for possibledifferences between the different farming and feeding systems.The following criteria were evaluated:

- Smell of the fresh meat

- Palpable characteristics of the fresh meat

- Visible fat deposits

- Smell of the cooked meat

- Taste of the cooked meat

- Tenderness of the cooked meat

Customer preferences

Altogether 812 persons were questioned concerning their rating of the importance of farming and feeding systems respecting animal welfare. Another goal was to determine their willingness to pay a higher price for meat which had definitely been produced ecologically and with respect for animals. The questioned persons were customers and visitors of the farms where groups A, B and C were raised.Criteria of the questionnaire:

- Type of farming – extensive/intensive

- Origin of the meat – traceable (regional producer)/anonymous (wholesaler/importer)

- Quality of the meat – regional producer/anonymous producer

- Product safety – regional producer/anonymous producer

- Higher price for special quality

Results and discussion

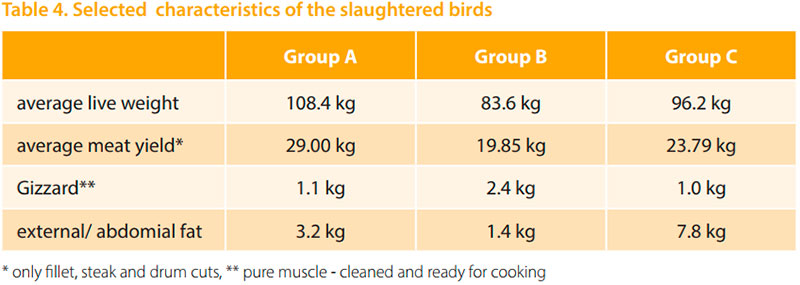

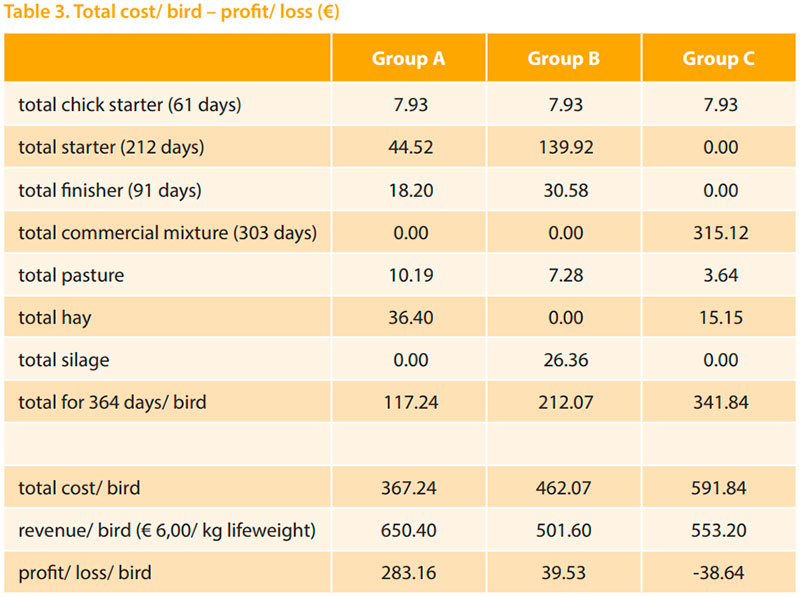

The tables 2 – 5 clearly show that birds of group A, browsers supplemented with a limited amount of the above described farm ration, were not only raised at the lowest cost but also provided the highest meat yield. Feed costs of group C, raised intensively and using commercial mixtures, were almost three times as high as in group A, and the amount of abdominal fat was by far the highest of all groups – due on the one hand to lack of exercise, but presumably also because of high energy levels in the commercial feed.Group B, where the farmer altered the ration arbitrarily several times, provided the poorest meat yield. While these birds had almost no abdominal fat, the weight of the gizzard was the highest of all groups. The farmer had partly fed coarse silage which increased the activity of the gizzard and consequently its size.

The profit/loss account (end of table) shows the direct relation between feed costs and economic success. All remaining production costs (investments, labor and slaughter, but without entrepreneurial wages) come to a steady average of € 250.00 per bird in Central Europe and Poland. Including feed, the total cost of production per bird in the study was € 367.24 in group A, € 462.07 in group B and € 591.84 in group C.

In long-term comparison, a farmer in these countries achieves an average of about € 6.00 per kilogram of life weight when selling cuts of slaughtered ostriches. Birds of group A at an average life weight of 108,4 kg achieved of € 650.40, goup B at 83.6 kg achieved € 501.60 and group C at 92.2 kg achieved € 591.84.

The profit/loss account reveals a surplus of € 283.16 per bird of group A. The results in group B are also cost-covering, but a modest € 39.53 per bird can hardly ensure the survival of the farmer, unless he raises extremely large numbers of birds – which is unrealistic under Central European circumstances. Group C produced a deficit of € 38.64.

Gizzard and Abdominal fat showed significant differences (Table 4). Birds of group B were fed a very coarse, hard silage during fall and winter, which stimulates the gizzard activity. It is assumed that the low live weight and meat yield was caused by the low level of metabolisable energy of the diet and the high energy requirement for the activity of the gizzard. The thick layer of abdominal fat in group C is a result of lack of exercise because of small paddock size combined with consumption of highenergy pelleted feed.

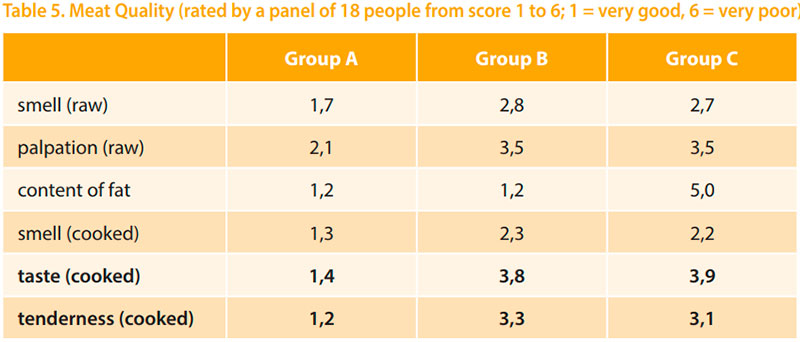

Table 5 shows that meat from the extensive system (Group A) showed the best scores throughout the criteria. Group B and C had generally higher scores than group A, with the exception in fat content. In this trait group B showed the same value as group A (1.2), but the score of group C was extremely poor (5.0). The high fat content of group C especially in Fan Fillet and Triangle Steak (Figure 2 impaired the acceptance by the consumers.

Figure 2. Intensive farming with limited space to move and highly concentrated feed results in clearly visible layers of intramuscular fat (A), while physical exercise and forage as main feed resource in the extensive system produce very lean meat (B) which is preferred by consumers.

Customer Preference

763 persons were interviewed concerning their acceptance of ostrich meat from extensive or intensive farming, from known (regional) or unknown (international) origin, and concerning their willingness to pay more for meat from known rather than unknown production. 92.2 percent of respondents preferred meat from extensive farming and 78.6 percent from known sources. 83.5 percent were willing to pay a higher price for meat from extensive farming because they believe that this product is of higher quality and produced without additives, and thus safer for the consumer.The present study must be understood as a first step to come closer to the ideal way to farm and feed ostriches. Data from only few farms and three systems were evaluated, and obviously more investigation is needed to come to clear results for other parts of the world and for other feeding systems.

It would further be important to find out if, and to what degree, an improved system of feeding could enable farmers to slaughter ostriches at an earlier age with a higher meat yield – yet without losing meat quality (consistency of muscle, higher proportion of intramuscular fat), as is the case with most other animal production. This, however, needs more knowledge about the true nutrient requirements of the ostrich – so far feed formulas are merely based on farmers’ practical experiences.

The ostrich branch must find an answer to its basic question: Can an industrial system of farming, which pushes birds to their genetic limits of growth, be a prime goal of the branch? Or should not, on the contrary, the inherent advantages of the ostrich – healthy, lean meat, hypoallergenic character of its products… – be supported by natural farming and feeding systems?

Until now the annual world production of ostrich meat (prime cuts = fillet, steak, drum) has never exceeded 7000 tons. Even if increased by 200% to approximately 20,000 tons, ostrich meat would still amount to no more than 0.008% of the world’s total meat production (without fish). This taken into consideration, the branch must decide urgently which goal to head for: an industrialization of production or rather the cultivation and promotion of the very special and „green” niche product ostrich.

Conclusions

In spite of the many open questions, this study demonstrates that an extensive farming and feeding system based on the biological characteristics of the ostrich reaches the best results at the lowest expenditures. The „ecological” way of farming is the ideal road to economic success for ostrich farms operating in moderate climate zones with lush vegetation.Further, the quality of the meat is judged to be superior if produced under extensive rather than intensive management and feeding conditions.

The customers would rather buy meat from extensive production systems and are even willing to pay a higher price for it because they are convinced of the better quality and improved product safety. Industrial, intensive farming and the use of industrially-produced feed – as is prevalent today even in countries with moderate climate and good pastures – is not accepted by the customers and endangers the survival of the farms because of high production costs and low margins.This is not only the problem of hot and arid regions but also of countries and farms applying the intensive system for lack of space or because of an obsolete view of livestock farming.

The strict and pioneering new standards issued by the German Department of Agriculture practically force German ostrich farmers to come to an economic way of ostrich keeping which at the same time ensures the welfare of the birds. As an additional beneficial effect for producers as well as for animals the consumer has a positive image of German ostrich farming and appreciates the products farmers can offer with self-respect.