Abstract

Induced molting is a management tool to extend the productive life of laying hens. National statistics on molting from previous years indicate that about 20% of the laying hens were molted in the USA (table 1), compared to less than 10% in Germany (table 2). Information from the industry and independent poultry consultants in the USA suggests that currently most flocks are being molted, while egg producers in Germany are more concerned about objections from animal welfare and the response of hens in non-cage systems. Since 1986, the North Carolina Cooperative Extension Service has designed and carried out Layer Performance and Management Tests to compare different strains under different management systems. Results of the latest two tests were analyzed to study the potential benefit of molting compared to single cycle management in terms of annual egg production and egg income over pullet and feed cost. A non-fasting molt was induced at 69 weeks of age, with target weight reduction by 25% in the 38th NC test and 20% in the 39th NC test. Under the conditions of these tests and the assumptions made, economic benefits of molting are obvious if molted hens are compared to non-molted hens kept to the same age of 109 weeks. However, annual egg production will always be higher and egg income over pullet and feed cost seldom lower if the single cycle is extended to about 60 weeks of production.

Keywords

laying hens, molting, economics, animal welfareCo-Authors

Kenneth E. Anderson, Raleigh, North Carolina, USA

Introduction

Before egg production became the full-year round business we know today, chickens followed a similar annual cycle as all birds: reproduction in the spring, rearing through summer, and molting in the fall. Shortage of eggs during winter months generated a strong interest on the part of egg producers and researchers to develop ways and means to shorten the molt period and/or to change the time of molting to benefit from seasonal demand and corresponding egg prices. Primary reeders of egg-type chickens responded to the challenge by focusing on improved persistency of egg production and shell quality.Decisions on molting must be based on the performance profile of commercial layers, approved methods of molting, and the demand for eggs at heavier weights.

About 30 years ago, Wolford (1984) reviewed the literature on induced molting, with focus on questions which required further research. The oldest reference cited in this review is Bulletin 258 of the Cornell Experiment Station (Rice et al., 1908). However, Rice (1905) had already published on molting three years earlier. Details of the nonanorexic (non-fasting) method of molting applied in the North Carolina Layer Performance and Management Tests are described in each report and special publications of the North Carolina Cooperative Extension service and may be downloaded from the internet. We will present statistics on the frequency of molting and analyze results of the 38th and 39th NC Test for traits of primary interest. Reasons for molting and differences between the egg industry in the USA and Germany will be discussed.

Frequency of Molting in the USA and Germany

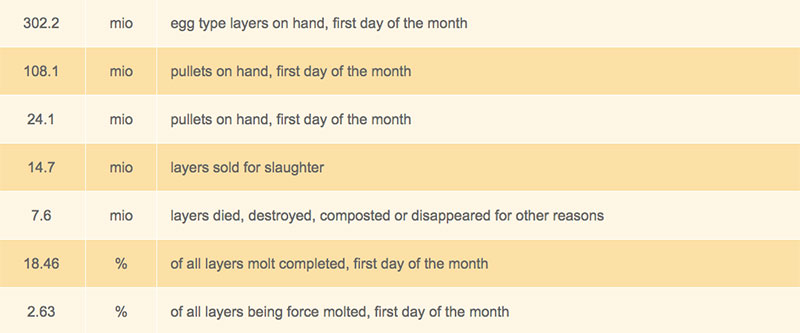

In the USA, each State reports data on egg production to the Census Bureau on a monthly basis from farms with at least 30,000 birds. These statistics are summarized and published annually by the USDA. Table 1 shows the average population of pullets and laying hens in 2013-14.Table 1: USDA (2015) Statistics on pullets, laying hens and molting in the USA

If we multiply the percentage of layers recorded on the first day of the month (18.46%) by 4 (number of weeks for a molting program), we may assume that 74% of the hens were molted. Anderson (2015) recently noted that “current industry practice is to molt over 80 percent of the caged egg type hens in the United States” – mainly in response to the Avian Influenza outbreak in 2015. In case of major disease breaks, shortage of pullets and restrictions on bird movement, the option to molt has obvious advantages.

If we multiply the percentage of layers recorded on the first day of the month (18.46%) by 4 (number of weeks for a molting program), we may assume that 74% of the hens were molted. Anderson (2015) recently noted that “current industry practice is to molt over 80 percent of the caged egg type hens in the United States” – mainly in response to the Avian Influenza outbreak in 2015. In case of major disease breaks, shortage of pullets and restrictions on bird movement, the option to molt has obvious advantages.

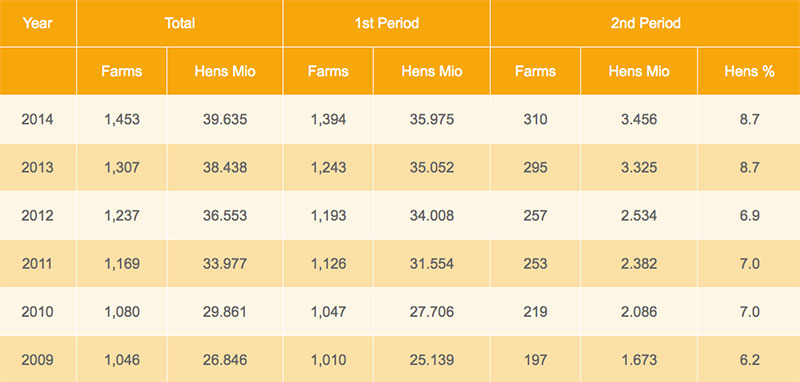

In Germany, monthly data are reported to the Federal Statistics Office for flocks with at least of 3,000 hens. The statistics in table 2 were published by MEG (2015) to show developments since the exit from conventional cages in 2009. Molting appears to have increased slightly since the transition to non-cage systems.

Table 2: December statistics on laying hens in Germany (MEG, 2015)

Different grading systems and assumptions regarding egg prices must be kept in mind when assessing the potential benefits of molting in the United States and in Germany. The egg prices used in the NC tests to calculate egg income are based on current production year and applying a 3 year average egg price on egg production and quality evaluation. Table 3 shows average prices across both tests.

Table 3: USDA vs. European Egg Size Grading Standards and Egg prices assumed in the 38th and 39th North Carolina Tests

In the NC Layer Performance and Management Tests, the egg size distribution is determined at 28-day intervals, weighing all eggs produced within the previous 24 hours and grading according to USDA standards. All eggs above 63.8 grams were classified as “extra large”, and there was no incentive to produce more “Jumbo” eggs. In Germany, by contrast, eggs above 73 g can generate extra income for producers, provided shell quality is acceptable. From the difference in egg prices, one would expect more molting in Germany than in the USA, but the opposite is true.

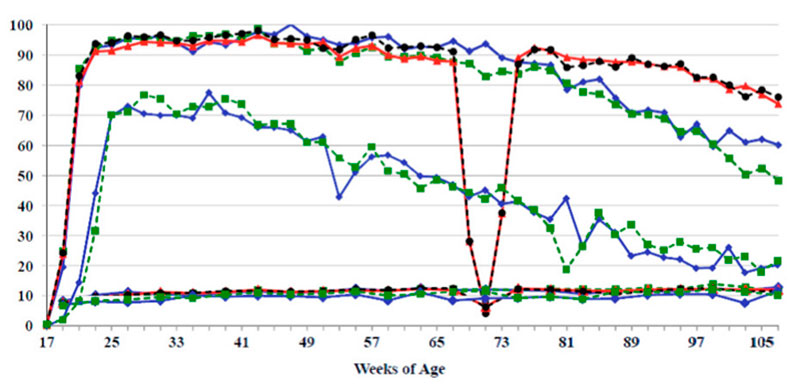

Fig. 1: Combined effects of feed composition and reduced day length on rate of lay in molted vs. non-molted commercial white egg layers (Lohmann LSL Lite) and a control line (NC Barred Plymouth Rock); combined from graphs 4 and 19 in the final report of the 38th NC Test

Results of 38th NC Test: molting with 25% target weight loss

The non-fasting method of molting applied at the North Carolina Experiment Station in conventional cages has been described by Anderson (2015) and can be downloaded (http://content.ces.ncsu. edu/print/induced-molting-of-commercial- layers). The 38th NC Management Test focused on a comparison of molted vs. non-molted hens from 17 to 109 weeks of age (92 weeks of lay). Molted and nonmolted hens were kept in different rows of the same house and exposed to the same reduction of light hours.Table 1 shows the bi-weekly rate of lay of molted vs. non-molted hens of a modern commercial white-egg strain and the Barred Plymouth Rock control line maintained at the North Carolina State University as a measure of genetic progress.

The non-molted hens should have been more persistent if the day length had been kept constant and the difference is overestimated, but modern layers respond less to reduced day length than perhaps expected. The desired interruption of egg production requires a dramatic change in feed composition, and this was achieved with the feeding program used.

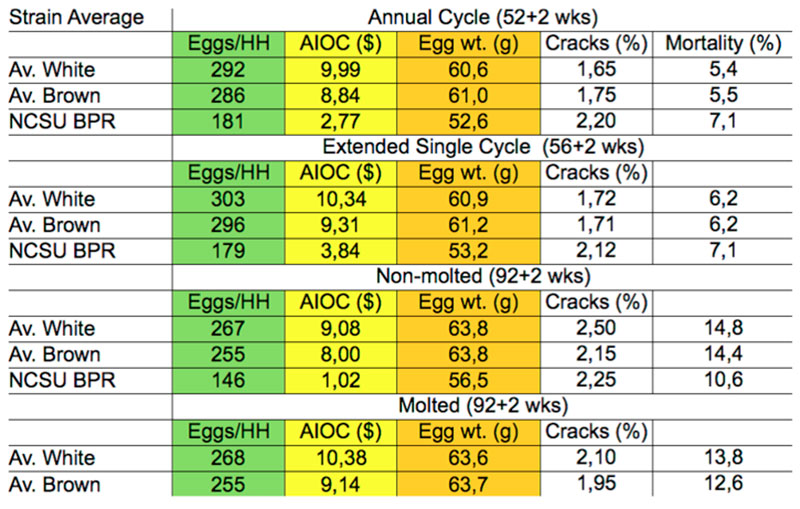

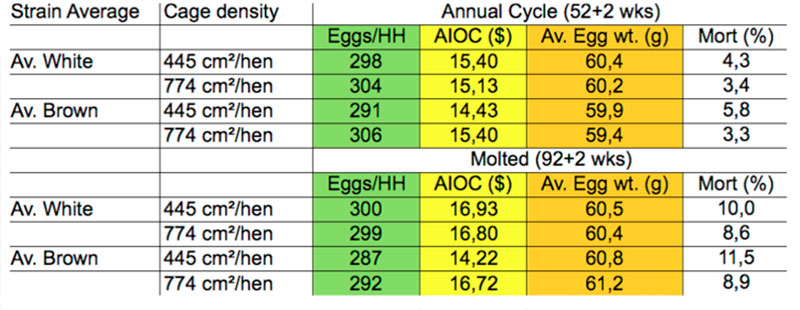

In table 4, the results of white-egg and brown-egg strains before, during and after the molt are summarized for annual egg number per hen housed and egg income over pullet and feed cost for different lengths of laying period, with and without molting. US$ 4.00 are assumed for 17 week old pullets and two weeks between flocks for maintenance, cleaning and disinfection. The figures for egg income and feed cost are taken from the final report; the formula for conversion to annual income over pullet and feed cost is shown below table 4. Similarly, hen-housed egg production is converted to annual results.

Table 4: Annual egg production per hen housed, egg income over pullet and feed cost (AIOC*) and average egg weight for different placement schedules in the 38th NC Test, assuming 2 weeks for depletion, cleaning and service before housing the next flock

Under the conditions of the 38th NC test, significantly more eggs per year would be produced with replacement after 52 or 56 weeks of production than with molting. Egg income over pullet and feed cost would be slightly lower for white egg strains, but higher for brown egg strains after 56 weeks of production than with molting and a second laying period to 109 weeks of age. Average egg weight was about 3 grams higher for hens kept until 109 weeks of age, regardless whether they were molted or not. Although molting is generally expected to improve shell quality, the difference in terms of % cracks was small to 109 weeks of age. Mortality was about 1% lower in molted than non-molted hens, which indicates that the molting procedure applied did not compromise the welfare of the hens in terms of livability. These results confirm that molting is economical if hens are kept to 109 weeks of age, while even better results may be obtained with single cycle management and more than 56 weeks of production.

Results of 39th NC Test: molting with 20% target weight loss

In the 39th NC Test, all hens in conventional cages were molted without a nonmolted control, and the target weight loss during the molt was 20%. Significantly higher egg production and egg income over feed cost than in the previous test suggests that 20% weight reduction should be preferred and 25% weight loss may be too much. The results are summarized in the following table 5.Table 5: Annual egg production per hen housed, egg income over pullet and feed cost (AIOC*) and average egg weight for different placement schedules in the 39th NC Test, assuming 2 weeks for depletion, cleaning and service before housing the next flock

Livability was somewhat better at the lower density, but the effect on egg income over pullet and feed cost would not be sufficient to convince egg producers to reduce the stocking density unless dictated by animal welfare standards. The calculated advantage of molting across both types of layers and cage densities was 1.08 $ per hen per year, compared to a short cycle of 52 weeks. However, the difference may be non-significant compared to single cycle management with optimum length of laying period.

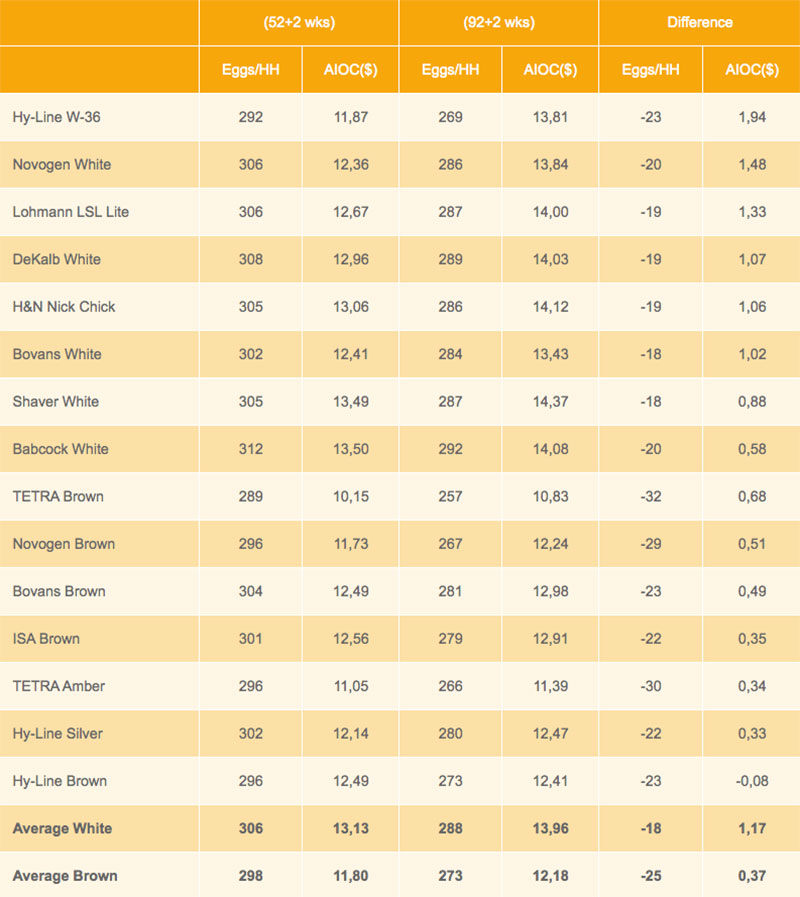

Interactions between strains and moltability

In the final report of the 38th and 39th NC Tests, detailed results for different cage systems, bird densities and age periods are documented in 90 tables, separate for white-egg and brown-egg layers (https://poultry.ces.ncsu.edu/layer-performance/).In the following table 6, hen-housed egg production and egg income over feed cost is summarized from 12 tables in the final report of the 39th NC Test and corresponding results from the 38th NC Test for 8 white-egg strains and 7 brown-egg strains represented in both tests.

The strains are sorted on the last column to show the apparent benefit of molting for different strains. Annual egg income over cost (AIOC) during the first 52 weeks is highly correlated with AIOC in 92 weeks (r = 0.87), because the first period is part of the total, but AIOC during the first 52 weeks is a poor predictor of the additional gain after the molt (r= 0.11). Nevertheless, egg producers will be more likely to molt flocks with low mortality and superior performance during the first cycle.

Discussion

The potential benefit of molting in terms of annual egg income over pullet and feed cost depends on many factors, including regional demand for eggs at specific weights, available rearing capacity or replacement cost for pullets, availability of suitable components for molt feed and total feed cost. Under the conditions of the NC Tests, most white-egg strains produced more egg income over pullet and feed cost during the first 52 weeks of production, and the additional gain from molting also favored white-egg strains.

Preferences for shell color and egg weight are usually dictated by the regional egg market. Primary breeders offer a range of strain crosses with different average egg weight and advice how to optimize the egg grading results with a combination of different management tools, including feed formulation, house temperature and placement schedule. Egg producers keeping weekly records on egg income and feed cost can monitor cumulative egg income over pullet and feed cost and use this information to optimize future placements.

Arguments pro or con molting may be seasonal fluctuations in egg prices or cash flow, long-term contracts with pullet growers or limitations in getting spent hens slaughtered. The apparent well-being of the hens may be an argument (pro or con), especially if consumers like to know under which conditions eggs are produced and are willing to pay for the additional cost. In another context, Vukina et al. (2013) studied the economic impact of investments in improved living conditions for laying hens in the National Organic Program and concluded that the current market prices reflect the willingness of consumers to pay for the cost of animal well-being. Keeping the birds calm during the molt with reduced day length and light intensity helps to minimize mortality, but may be in conflict with poultry welfare regulations. Providing low density feed and access to water should assure low mortality and acceptable hen welfare.

The optimal strategy for target weight reduction during the molt is subject to further studies and field experience with different strains. Comparing the results of the 38th and 39th NC tests, 20% weight loss seems to be better than 25%. Since properly fed laying hens have no fat to lose when the molt is induced, and pullet weight just before onset of lay may be a better target than pre-molt body weight (Drinoczy, 2016). The impact of flock uniformity before the molt and individual weight changes during the molt would be of interest in future studies.

We are not aware of experimental results with molting in enriched cages or noncage systems. Since the ban on conventional cages, most egg producers in Germany changed to aviaries. Official statistics for eggs produced in 2014 were: 63.3% barn, 17.3% free range, 10.5% Kleingruppenhaltung (enriched cages), and 8.9% organic (DGS 3/2016). In other European countries, enriched colony cages are preferred over floor systems. In Lower Saxony, the State with the highest concentration of poultry in Germany, about 10% of the hens are molted on farms between 3,000 and 30,000, about 9% above 30,000 hens. In Northern and Eastern Germany, average farm size is larger and the percentage of molting is lower than in Southern Germany, where smaller flocks with direct marketing are more common (Oltmann (2016). Small producers may prefer to buy spent hens from flocks with excellent first cycle performance to produce mainly extra large or “jumbo” eggs with superior shell quality after the molt instead of competing in the usually oversupplied market for medium and large eggs (cf. table 3).

In a previous study, Schulte-Drüggelte and Thiele (2013) used data from the 38th North Carolina layer performance and management test and production standards for LSL Lite layers for an extended single cycle laying period. In the present study we included additional data from the recently published 39th NC Test and tried to answer the question why molting is more widely practiced in the USA than in Europe. Due to the European grading system, average egg size in the lifetime of most flocks in the EU is about 63 g to meet the demand for the volume trade of discounters. Different strain crosses and management (nutrition, length of laying period and house temperature) have to be combined to meet egg demand and maximize farm income.

Table 6: Annual egg production and egg income over pullet and feed cost for 15 strains represented in the 38th and 39th NC tests, assuming 2 weeks for depletion, cleaning and service before housing the next flock

*AIOC 52 = 52 x (EI – FC – PC)/54; AIOC 92 = 52 x (EI – FC – PC)/94

Summary

Results of the 38th and 39th North Carolina layer performance and management tests were analyzed and implications for US and German egg producers discussed. Decisions on molting will be mainly based on the demand for eggs in different weight grades and economic evaluation of production cost per marketable egg. Under the conditions of these tests in conventional cages, most white-egg strains outperformed most brown-egg strains in terms of egg income over feed and replacement cost when molted and kept to 109 weeks of age. With a weight loss of 20% (compared to pre-molt weight), better results were obtained than with 25% weight loss. In Germany and other European countries, single cycle management with about 60 weeks of production is more common than in the USA, which is partly explained by the prevalence of brown-egg layers and a lower share of egg production for the breaking industry. The non-fasting molting program used in North Carolina had no negative impact on bird welfare in terms of livability.

Literature

Anderson, K.E. (2012) Final Report of the 38th North Carolina Layer Performance and Management Test. https://poultry.ces. ncsu.edu/layer-performance/Anderson, K.E. (2015) Induced Molting of Commercial Layers. http://content.ces. ncsu.edu/print/induced-molting-of-commercial-layers

Anderson, K.E. (2015) Final Report of the 39th North Carolina Layer Performance and Management Test. https://poultry.ces. ncsu.edu/layer-performance/

Anderson, K.E. and G.B. Havenstein (2007) Effects of alternative molting programs and population on layer performance: Results of the Thirty-fifth North Carolina Layer Performance and Management Test. J. Appl. Poultry. Res. 16:365-380.

Drinoczy, J. (2016) Personal information.

MEG-Ausgabe Eier & Geflügel, KW 44, 31.10.2014.

Oltmann, D. (2016) Personal information. Rice, J.E. (1905) In: The Feeding of Poultry, The Poultry Book, ed. W.G. Johnson and G.O. Brown. New York: Doubleday, Page and Co.

Schulte-Drüggelte, R. and H.-H. Thiele (2013) Determining the optimum replacement schedule for commercial layers: does molting pay off? Lohmann Information 48(1): 47-52.

USDA (2015) Chickens and Eggs Summary 2014. Feb. 2015.

Vukina, T., K.E. Anderson and Mary K. Muth (2014) Economic effects of proposed changes in living conditions for laying hens under the national organic program. Appl. Poult. Res. 23: 80-93. http://dx.doi. org/ 10.3382/japr.2013-00834

Wolford, J.W. (1984) Induced molting in laying hens. World‘s Poultry Sci. J. 40:66-73.