Abstract

Distillers Grains are a cereal byproduct of distillation for bio-energy, ethanol production and of growing interest for the feed industry. DDGS is a raw material rich in crude protein and amino acids as well as some minerals, e.g. phosphorus. In this review, the nutrient content of DDGS is compared with corn and wheat.

DDGS from wheat has a higher content of crude protein and amino acids than corn based DDGS. If DDGS is to be used in diet formulation for laying hens, the first question is which grain was used for the production of DDGS. Matrix values are subject to considerable variation between DDGS sources, due to different plant material and ethanol production plants. To assure balanced nutrient content in the compound feed, it is not advisable to use the maximal possible level of a cheap, but variable raw material, and producers of DDGS are trying to achieve more predictable quality, with less variation from a single production facility. If DDGS is used to partially replace “soya 48 brasil” (46% CP), exchange factors of 2.2 for corn DDGS (26% CP) and 1.6 for wheat DDGS (33.5 CP) may be assumed. All ingredients of the cereals (without starch) will be increased by a factor of approximately 3. Quality standards should be verified before prices are taken into consideration. The plants selling DDGS should meet the required quality specifications, with nutrient specifications and proximate amino acids analysis, mycotoxin analysis and physical samples of the products.

Scientific trials and practical experience have shown that DDGS from corn, wheat and other cereals can be a valuable and cost effective raw material in feed formulation for poultry and especially for layers. In view of limitations in the international raw material market, DDGS offers an opportunity to minimize the cost price of nutritionally optimal diets for laying hens.

DDGS from wheat has a higher content of crude protein and amino acids than corn based DDGS. If DDGS is to be used in diet formulation for laying hens, the first question is which grain was used for the production of DDGS. Matrix values are subject to considerable variation between DDGS sources, due to different plant material and ethanol production plants. To assure balanced nutrient content in the compound feed, it is not advisable to use the maximal possible level of a cheap, but variable raw material, and producers of DDGS are trying to achieve more predictable quality, with less variation from a single production facility. If DDGS is used to partially replace “soya 48 brasil” (46% CP), exchange factors of 2.2 for corn DDGS (26% CP) and 1.6 for wheat DDGS (33.5 CP) may be assumed. All ingredients of the cereals (without starch) will be increased by a factor of approximately 3. Quality standards should be verified before prices are taken into consideration. The plants selling DDGS should meet the required quality specifications, with nutrient specifications and proximate amino acids analysis, mycotoxin analysis and physical samples of the products.

Scientific trials and practical experience have shown that DDGS from corn, wheat and other cereals can be a valuable and cost effective raw material in feed formulation for poultry and especially for layers. In view of limitations in the international raw material market, DDGS offers an opportunity to minimize the cost price of nutritionally optimal diets for laying hens.

Keywords

nutrition, poultry, layers, raw materials, DDGS

Introduction

DDGS is a catchword often heard in the context of the worldwide raw material market for poultry feed. DDGS is a co-product of the bio-energy or ethanol industry when producing energy from sustainable sources. Those are mostly corn and wheat, but some other plant sources may also be used to produce bio-ethanol or energy in general. This article will mainly refer to the DDGS based on corn and wheat.

What is the meaning of DDGS?

Distillers Grains are a cereal byproduct of the distillation process. There are two main sources of these grains. The traditional sources were from brewers. More recently, ethanol plants are a growing source. It is created in distilleries by drying mash, and is subsequently sold for a variety of purposes, usually as raw material for livestock – in the past mainly or especially for ruminants. There are two common types of distillers grains:Wet Distillers Grains

Wet Distillers Grains (WDG) contain primarily unfermented grain residues (protein, fiber, fat and up to 70% moisture). WDG has a shelf life of four to five days. Due to the water content, WDG transport is usually economically viable within a short distance from the ethanol production facility only.Dried Distillers Grains

Dried Distillers Grains with Solubles (DDGS) is WDG – with the addition of some liquid co-products from fermentation, dried to 10-12 percent moisture. DDGS have an almost indefinite shelf life and may be shipped to any market regardless of its proximity to an ethanol plant. Drying is costly, as it requires further energy input. In the USA, DDGS is packaged and traded as a commodity product and sold on the world raw material market. With increasing production of ethanol from cereals in different parts of the world, we also find more DDGS being offered as raw material for livestock. From each metric ton (MT) of corn or wheat used for ethanol production we get about of 300 kg of DDGS (with 10% moisture).Market development for DDGS

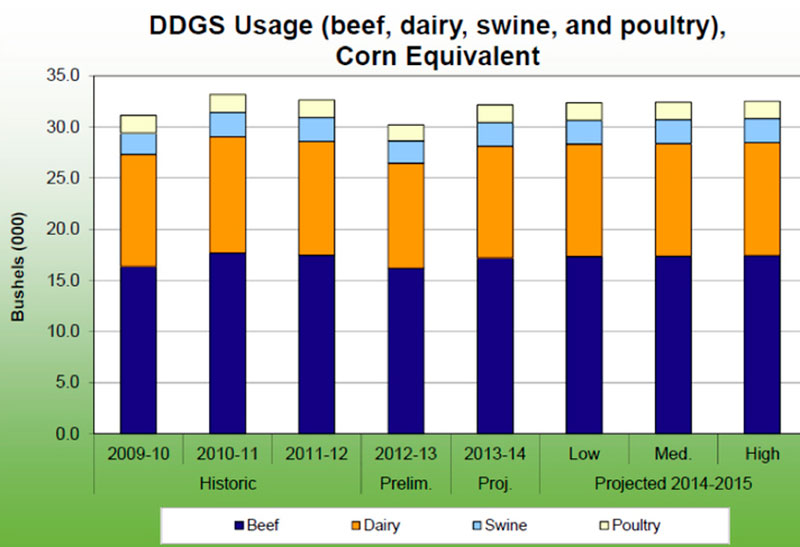

Since the development of the bio-energy and ethanol production, there has been a growing interest of the livestock industry to use the co-products for nutritional purposes. For decades, wet distillers grains (WDG) had been used as feedstuff for different livestock. Major interest started more recently since Dried Distillers Grains with Solubles (DDGS) became available in large quantity due to political programs with subsidies to encourage production of energy from sustainable sources. As a result, DDGS has become an interesting and cost effective raw material for livestock nutrition. The major share of DDGS will still be used in ruminant nutrition, but there is also ongoing scientific research and practical experience in using DDGS in poultry nutrition (fig. 1).

Fig. 1: Usage of DDGS in feed for different species

Source: Ag MRC agricultural marketing resource center, 2014 courtesy of Dr. Robert Wisner rwwisner@iastate.edu

Nutritional value of DDGS

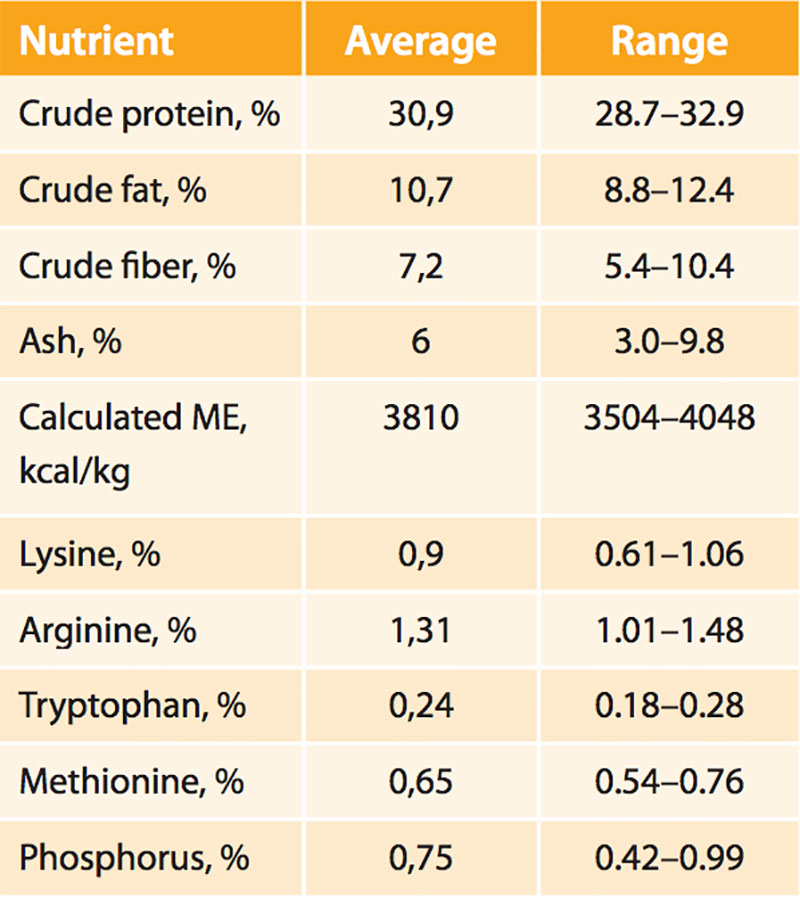

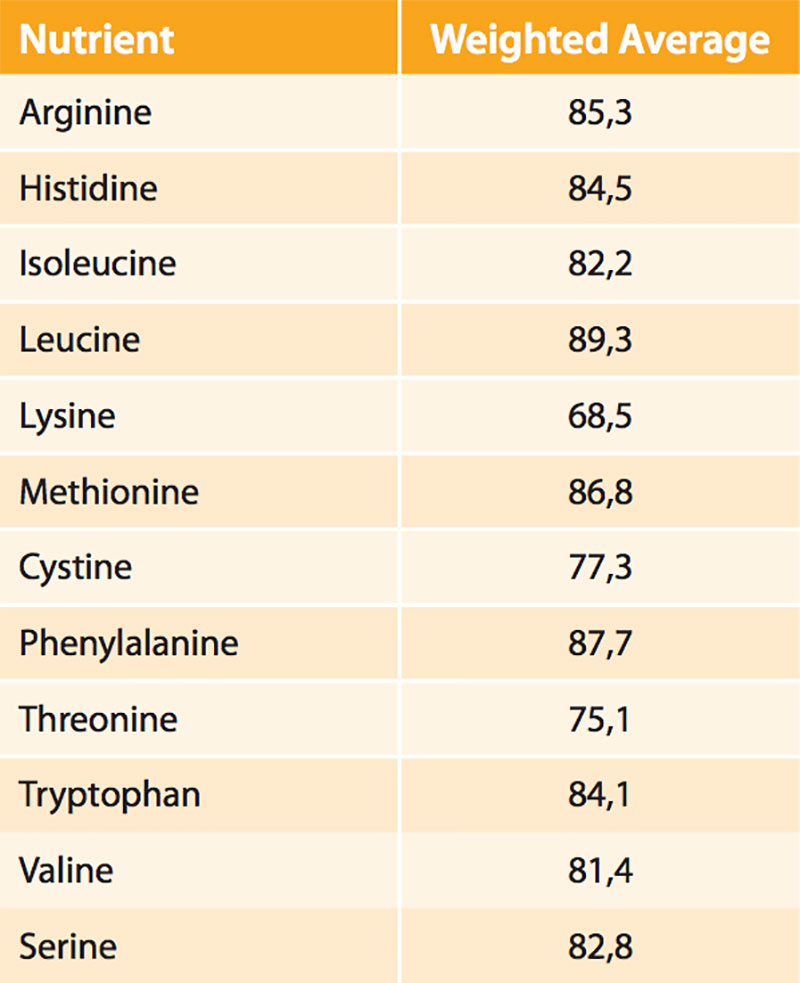

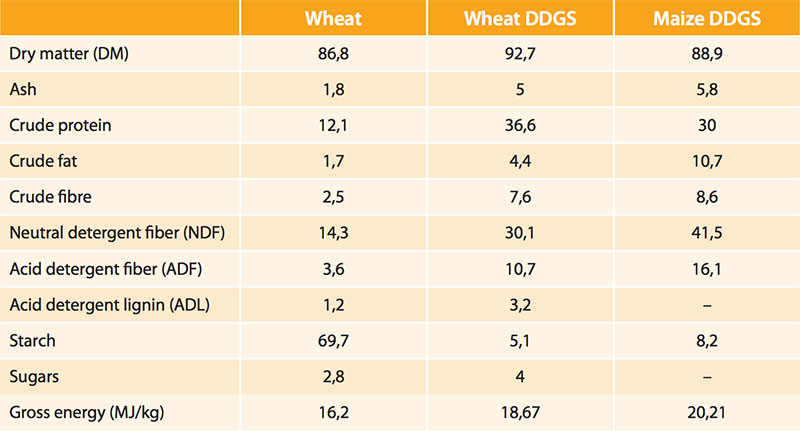

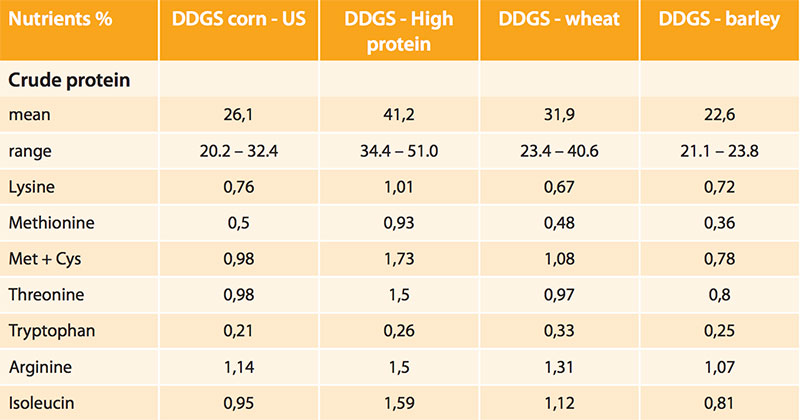

DDGS basically can be described as raw material quite rich or dense in crude protein (CP) and amino acids (AA) together with some minerals, this mainly in regard to phosphorus. During the production of ethanol from wheat or corn mainly the content of starch will be fermented into ethanol and the residual nutrients will be concentrated in the “left-over” of the process. The nutrient content of DDGS will be related to the nutrient content of corn and wheat; i.e. DDGS from wheat will show a higher content of crude protein and amino acids compared to corn; the different content of crude protein in the two cereals will influence CP and amino acid content in DDGS as well (tab. 2 and 3).If nutritionists want to use DDGS in diet formulation, the first question should be which grain was used for the production of DDGS, to get an idea of the nutritional value. But reliable matrix values are difficult to establish in view of the variation between DDGS sources – due to different plant material and even between ethanol production plants (tab. 1 and 4). This is still the most serious limitation for using higher inclusion rates for DDGS in poultry diets. For efficient growth or egg production, poultry in general needs a well-balanced diet with low variation in nutrient content in the compound feed to meet the nutrient demand of each single bird every day. Because of this, nutritionists prefer to avoid raw materials known to be variable or keep the inclusion levels in the formula low. To be on the safe side, each load of DDGS should be analyzed before higher levels of DDGS are included in poultry diets.

Table 1: Averages and ranges in composition of selected nutrients in different sources of corn DDGS

Source: U.S. Grains council // www.ddgs.umn.edu

Table 2: Digestible amino acid coefficients (%) of DDGS for poultry

Source: U.S. Grains council, cited from Waldroup et al. 2007

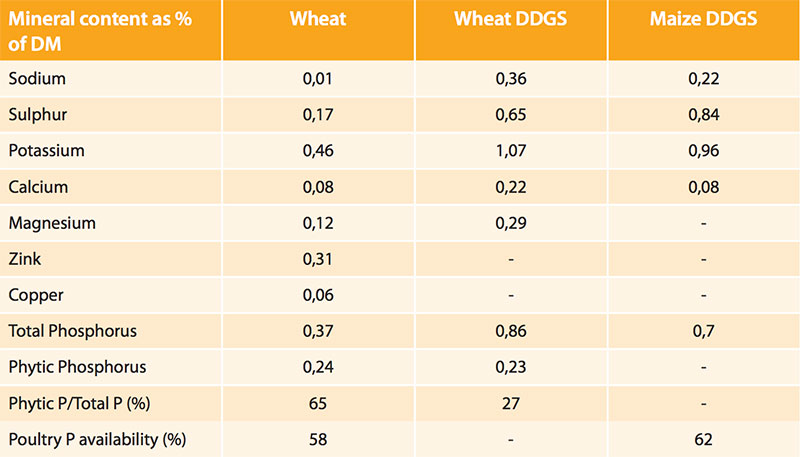

Table 3: Composition of wheat compared with wheat and maize DDGS in % of DM

Source: Biofuel Co-Products as Livestock Feed, FAO 2012

Table 4: Mineral composition and phosphorus digestibility of wheat compared to wheat DDGS and maize DDGS

Source: Biofuel Co-Products as Livestock Feed, FAO 2012

Table 5: Varying nutrient content of different DDGS sources, 88% dry matter

Source: Evonik AminoDat 4.0

All the data above very clearly illustrate the major nutritional challenge with DDGS – which is the very big variation of the nutrient content – shown under the topic ‘range’ (tab. 5). With the overall target to achieve a constant nutrient content of the compound feed, nutritionists will not use the maximal possible level of variable raw materials in diet formulation. Producers of DDGS are aware of this problem and try to achieve more constant quality with less variation from a single production facility. Furthermore there is an ongoing process to develop different specified co-products from the ethanol production, e.g. “high protein DDGS”. Nevertheless we are faced with the fact that DDGS is considered to be an interesting commodity in the international raw material market, which needs special attention concerning specified and reliable quality and nutrient content.

DDGS offers a chance to reduce dependence on soya

DDGS is considered as a ‘middle protein carrier’, with typical content of crude protein (CP) between soybean meal (higher) and corn (lower). DDGS can contribute some of the crude protein (and amino acids) requirements and reduce the level of soybean meal and even full fat soya in diet formulation. As all soybean products are a ‘wanted’ raw material with high price volatility around the world, the inclusion of moderate levels of DDGS in poultry diets may offer chances for cost saving. In comparison to “soya 48 brasil” with 46% CP one can assume exchange factors of 2.2 for corn DDGS (26% CP) and 1.6 for wheat DDGS (33.5 CP). This means that each 1% soybean meal can be replaced by 2.2% corn DDGS and by 1.6% wheat DDGS. This exchange factor may vary to some extent according matrix evaluation in detail. The amount of cost saving will depend on the actual price setting when offering DDGS into the diet optimization, especially in relation to prices of soybean products.Color of DDGS

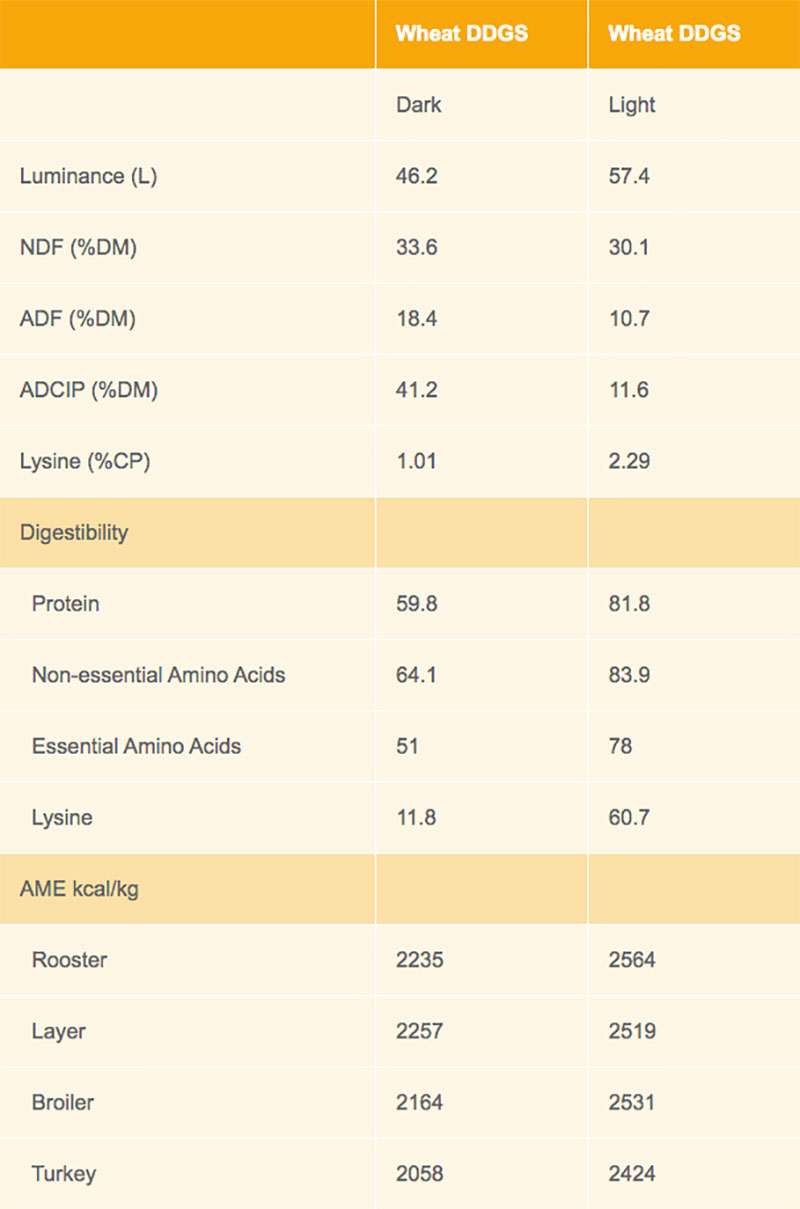

The color of DDGS gives a first indication of the quality, lighter and more yellowish color indicating a higher quality with higher amino acid digestibility than DDGS with darker and brownish color. This is due to the fact that AA can undergo the Maillard reaction and AA (especially Lysine) can be combined with carbohydrates rendering them un-digestible for the animals. It is thought that the dark color may result from drying of the wet DDGS in the plants at too high temperature. The variation which may be found among samples is shown in Fig. 1.Recently scientists have established additional quality indicators for an easy and quick quality test. Color is only a first indicator and should be combined with standard laboratory tests (tab. 6).

Fig. 2: Variation of DDGS color in different samples

Photo: courtesy of Dr. Jerry Shurson, Department of Animal Science, University of Minnesota.

Table 6: Digestive utilization of nutrients in wheat DDGS and the impact of color

Source: wheat DDGS feed guide – Canada (cited from Cozannet et al. 2009, 2010)

Contamination and unwanted residues

In DDGS everything from the basic cereal which has not been converted to ethanol and some minor co-products (for instance corn oil) during the fermentation process, will be concentrated. All ingredients of the cereals (without starch) will be increased by a factor of approximately 3. First of all, mycotoxins should be mentioned. DDGS from cereals with a high load of mycotoxins need regular monitoring of mycotoxin level in DDGS to avoid high contamination. To control and guide the fermentation process, some supplements with antibiotic activity have been used in ethanol plants and might be used in the future as well, specifically Virginiamycin, Penicillin, Erythromycin, Tylosin and Tetracycline. Salt (sodium-chloride) used as “drying agent” to speed up water absorption when drying the DDGS, will cause undesirable higher content of sodium in DDGS.Checklist when purchasing DDGS

Special attention needs to be paid to the quality of the DDGS to be used in poultry feeds as there is a large variation in quality between DDGS sources. Receiving low quality DDGS into a feed mill and including it in poultry diets can have negative economic consequences on bird performance. Poultry feed manufacturers must ensure they are procuring consistently high quality corn DDGS to capture the cost savings for their customers when using them. The following recommendations should be considered by poultry feed manufacturers for the procurement of DDGS:Know the source plant

The quality of DDGS can vary between and within manufacturing plants due to differences in manufacturing processes, process control, drying technology and ingredient quality control in the production of DDGS.Quality standards need to be established and verified before price is a consideration. Use an approved supplier process to select the plants which can provide DDGS that meet the required quality specifications. This includes nutrient specifications with proximate amino acids analysis, mycotoxin analysis, and physical samples of the products.

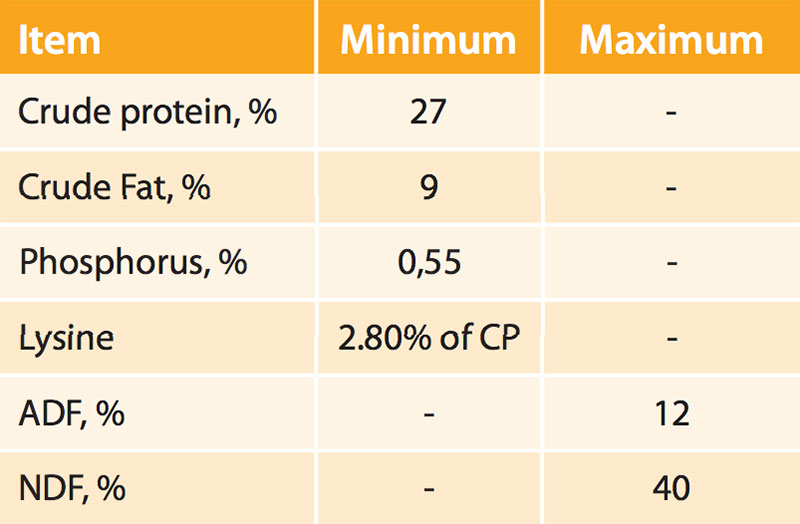

Recommended check list when buying corn DDGS.

Specify the source plant and DDGS quality in the purchase contracts

Incorporate the DDGS quality specifications including the analytical methods for nutrients and the name and location of the approved source plant into the purchase contract. Ensure that the supplier can trace the delivered DDGS back to the origin plant. This is especially important when the supplier is bringing multiple sources of DDGS into the commodity market as there is a risk that DDGS from different origins can be mixed up. Verify the supplier’s product liability insurance coverage.Inspect the load and retain a sample

Obtain a representative sample of the DDGS before unloading and verify that it matches the original sample. Inspect the color (a dark/brown color may indicate overheating and lower digestible lysine), check the odor (a burnt smell also may indicate overheating) and observe the bulk density and particle size. Reject the load if the representative sample does not closely match the original.Monitor DDGS for mycotoxins and nutrient content

Mycotoxin content in DDGS is threefold the level that may be present in the corn or wheat used for the production of ethanol. Mycotoxins are NOT harmed or even eradicated by the fermentation process of cereals into ethanol. Test the DDGS periodically for mycotoxin content to confirm that excessive levels are not present. Require routine nutrient information from DDGS suppliers.Inclusion of DDGS in layer diets

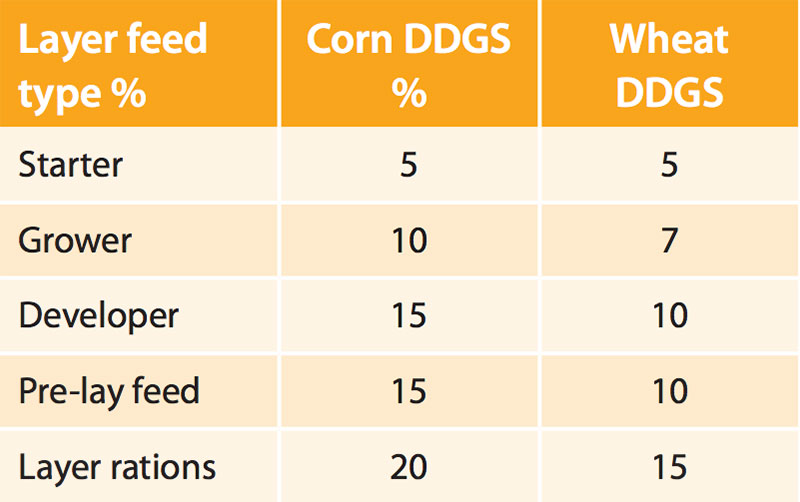

Based on a constant nutrient content with normal and good digestibility DDGS from corn, wheat and other cereals will be a valuable raw material and cost effective as well – under nowadays’ high price and volatile raw material markets. Scientific trials with layer breeds have proven that corn DGGS could be used with up to 30% in layer feed formulation. The level of inclusion being possible in practical layer diets is closely related to the amino acid digestibility and phosphorus availability; especially this aspect needs consideration because available phosphorus has become a quite costly nutrient constraint in diet formulation for poultry – especially in all vegetable diets (tab. 7). The proper DDGS nutrient matrices will, to a very large extent, determine maximum inclusion rates. It should be mentioned that Phytase and NSP-Enzymes are high value feed additives in association with the use of all kinds and sources of DDGS in diets for layers and for poultry in general.

Table 7: Recommended inclusion levels in practical diets for layers

Feed structure should never be compromised, otherwise daily feed intake might be reduced and DDGS blamed for it. DDGS from different production plants may show varying technical quality, i.e. in terms of flow-ability and specific weight, in addition to the variation in nutrient content. If buyers of DDGS are aware of these risks, they should be able to limit negative consequences.