Summary

Genetic and non-genetic factors influence egg weight of commercial layers and should be controlled

by farm management before production of a flock starts: the genetic profile of a strain cross with

regard to egg weight and correlated traits, the light stimulation during rearing and the bodyweight or

frame size development of the pullets. Once a flock is in production, the nutrient intake, especially

the early feed intake, has a major effect on the egg weight curve. Modern layer nutrition is focused on

meeting the demands of the birds at all times by adjusting the supply of nutrients according to daily

egg mass production and daily feed intake. Precision supply of nutrients influencing egg size is a tool

to adjust the egg weight on mid or short term basis. The option to increase egg size by molting,

keeping hens for two or more cycles, is losing support due to economic and welfare reasons.

Introduction

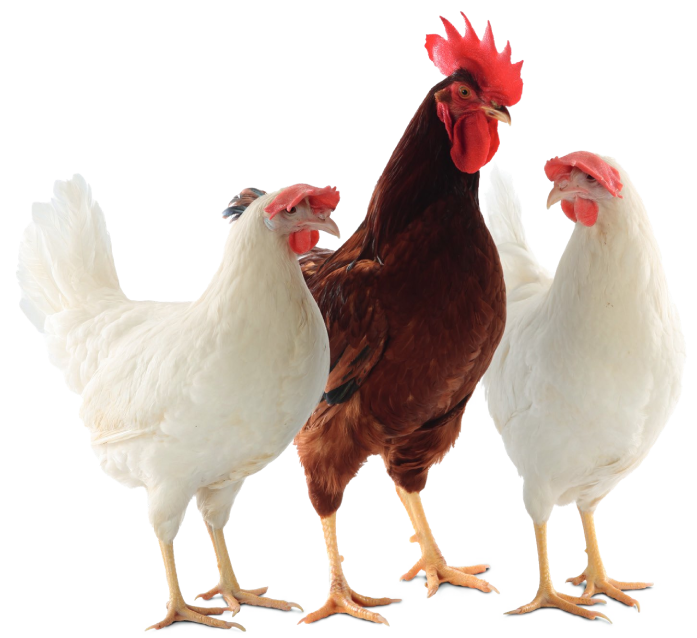

Commercial layer varieties from various breeding companies are available on the market. Their product profile can be distinguished, and management guides contain tables with expected egg weight and grading results per week of age under defined conditions. Numerous non-genetic factors will influence the ability of pullets or layers of the same variety to achieve the goals specified by the breeding company. These factors include body weight and frame development, nutrition, bird density in cages or floor housing systems, feeder and water space, lighting programs, housing and climate conditions, beak treatment procedures, vaccination schedules and diseases. This paper will focus on factors which can be manipulated by farm management to optimize egg weight during a full laying cycle.Product variety

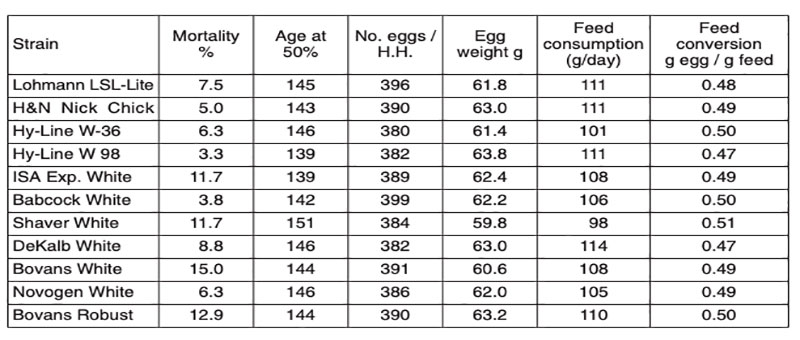

Today’s breeding companies and their multipliers offer a broad range of commercial layer varieties which differ mainly in shell colour, egg numbers and egg weight. If the demand of a given egg market is predictable on a long-term basis, the egg producers can choose a variety closest to market needs. Depending on these targets, the frequency of eggs in different grades can be optimized by choosing a commercial layer fitting to this demand. Table 1 indicates the range of average egg weight which may be found under identical conditions in a random sample test or on any farm.Table 1: Results of 38th North Carolina Management Test, white egg strains, single production

cycle from 119 – 595 days of age (North Carolina Cooperative Extension Service, 2011)

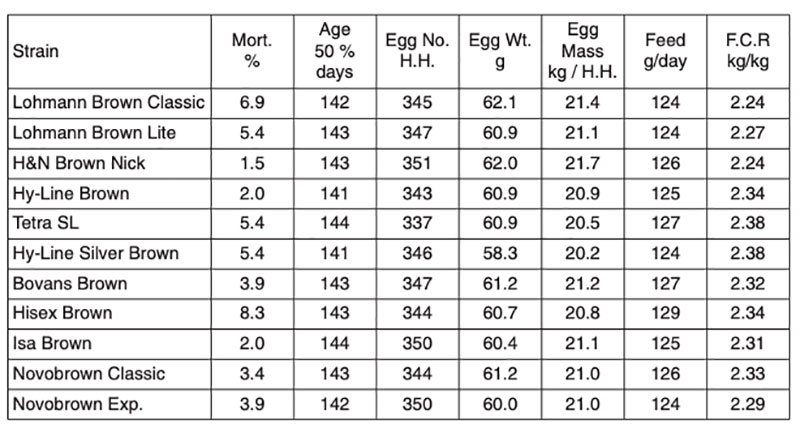

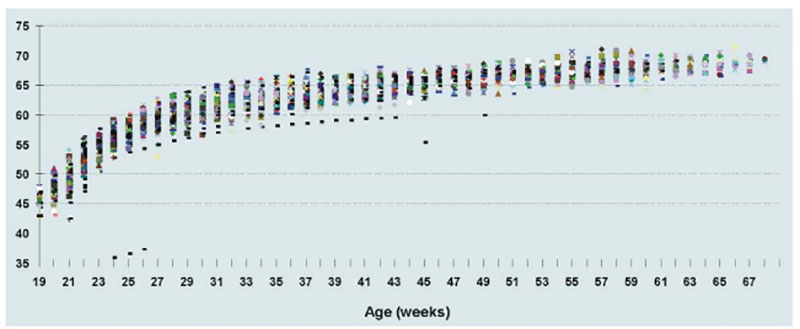

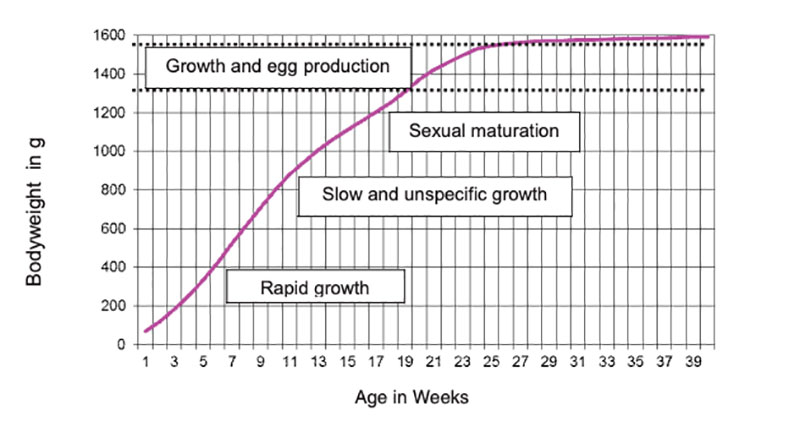

Compared to the rather small differences between strains in average egg size shown in tables 1 and 2, we find a huge variation in egg weight between hens of a flock at the same age, for the same hen at different age or between flocks of the same age and genetic background kept on different farms. Despite the rather high heritability of egg weight, it is also affected by major environmental effects. The egg weight curve in figure 1 documents field records with differences up to 5-8 g between commercial flocks with the same genetic potential, originated from a single GP flock.

Table 2: Results of XIXth International RST Ustrasice, Czech Republic,

18 to 74 weeks of age, average of conventional and enriched cages

(MEZINÁRODNÍ TESTOVÁNÍ DRBEZE ÚSTRAŠICE, 2011)

Figure 1: Variation in weekly egg weight between commercial brown-egg flocks with the same

genetic potential (Preisinger, 2002)

Egg producers should be aware of this non-genetic variation and learn to adjust the management and feeding in rearing and production to optimize their results.

Development of bodyweight, frame size and appetite

The first need of laying hens is proper brooding management. Adequate climate in the brooder house and suitable equipment to meet the chicks’ demands ensure a good start into their life. How to set up a brooding shed for layer chicks is described in all management guides for the different commercial varieties. The focus in rearing has to be on bodyweight development. After the chicks arrive and perhaps rest a bit after long travel, they should immediately start to drink and eat. A dense starter feed, high in energy and protein (with appropriate amounts of lysine and threonine), highly digestible for young chicks, is essential to reach target bodyweight. The high energy content of a starter diet should never be achieved by adding fat or oil containing saturated fatty acids, because young chicks cannot digest them. Vegetable oils with high amounts of unsaturated fatty acids as soybean or sunflower oil are the first choice.The change from starter to grower feed should be decided on target bodyweight, not at a fixed age. The grower feed is not as dense as the starter diet, but contains enough energy and protein to support further growth. The starter and the grower diets are fed ad libitum. Chicks have to be stimulated to eat as much as they can. Under normal conditions, they will easily reach their target weight. When they are 8 weeks old, a third diet, the so called developer feed, will be supplied. It contains a lower protein density, must have a good structure and 5 to 6 % crude fibre content. At this age, pullets should learn to empty the feeders: preferably every day, but at least several times a week. A balanced intake of coarse and fine feed particles and appetite before the next feeding will increase feed intake. The ability to consume large amounts of feed learnt during this phase will be crucial to the pullets after moving to the laying house, when feed intake has to increase sharply.

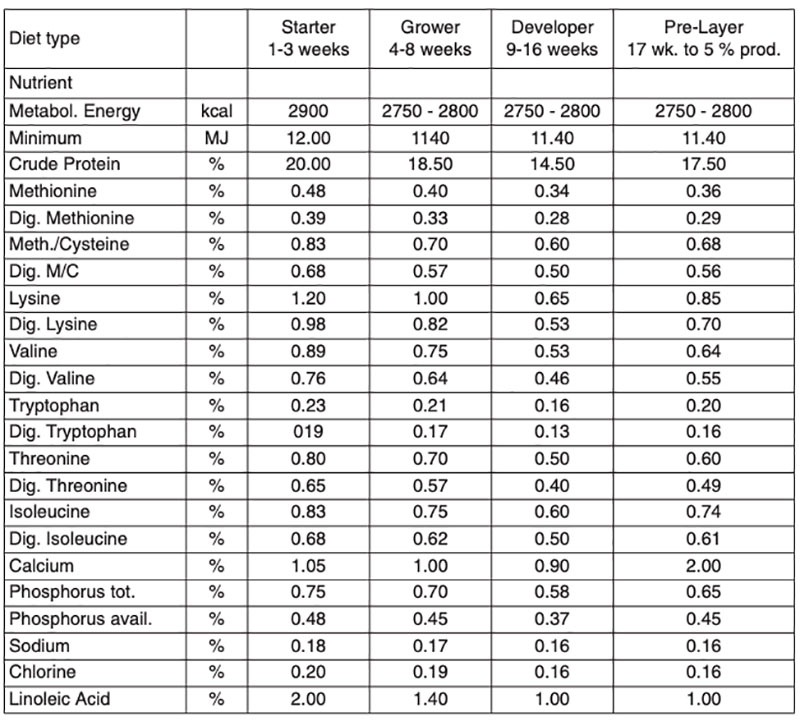

Sometimes modern layers have difficulties to consume enough feed shortly before and during the onset of lay, even if they are not selected for low feed intake like the Lohmann strains. In this case, they

Nutrient levels of different diets for LSL chicks and pullets (Recommended by

Lohmann Tierzucht, 2011)

will not gain or even lose body weight and have difficulties to reach good early egg size. Sufficient early nutrient intake is essential for a successful start and to reach high peak rates. Once the appetite of a flock is developed it should be maintained when birds are transferred to the layer facilities. A smooth transition to the high calcium amounts of a layer diet can be achieved by using a pre-layer diet with only 2-2.5% calcium. This diet, about 1 kg per hen fed for 10 days, makes the transition period from growth to lay easier for the hen, helps to maintain the feed intake and is a tool to improve the uniformity of a flock.

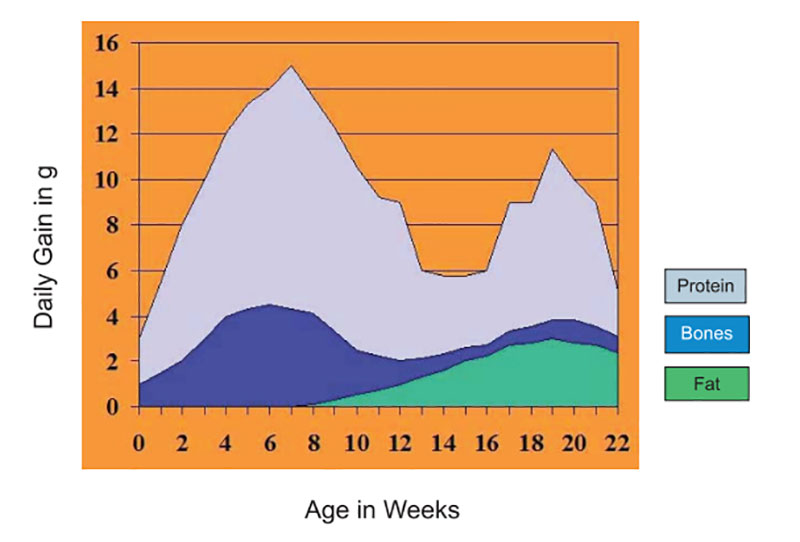

Many people still think that bodyweight at start of lay is the most important factor in relation to later egg weight. Our experience at Lohmann tells us that a much higher correlation exists between frame size development, i.e. bodyweight at 12 to 13 weeks of age, and later egg weight. At the age of 12 to 13 weeks nearly 95 % of the body frame is developed. A reduced frame size with corresponding underweight at this stage of development will have a lasting negative effect on egg weight. If a pullet is too small at this age, it can’t really catch up with bodyweight development. To gain bodyweight in the second half of rearing, some pullet growers push flocks with high feed densities. These birds will gain weight, but stay small and deposit more fat compared to properly reared birds. Pullets grown on high energy developer diets often exhibit poor feed consumption at the onset of lay (Elliot, 2002). They are not properly prepared for the laying period, because they are unable to eat enough at start of lay, often fail to reach the breeder’s standard for egg production and sometimes show problems like obesity and prolapse. Figure 2 illustrates that efforts to force up bodyweight after 12 to 13 weeks of age may end up with a small framed, fat pullet.

Figure 2: Development of body tissues of a commercial pullet (Ysilevitz, 2007)

If chicks are housed in floor systems or under hot climate conditions, they sometimes struggle to grow. In the first case, they are “wasting” feed energy for the higher activity; in the second case, they are not eating enough, because it is too hot. In both situations the chicks should be fed with higher feed densities until they reach their target weights. Prolonging the period feeding a starter or grower diet will help to achieve the target bodyweight. The period of supplying a less dense feed – the developer – will then be shorter than normal, but should still be used to develop the feed intake capacity as well.

Lighting program

The lighting program (day length and light intensity) for pullets and laying hens is a key factor in determining the onset of sexual maturity and egg production. Lighting programs for pullets in windowless houses can de designed to achieve optimal growth and efficient preparation for the laying period, largely independent of the season.After arrival of the chicks, the length of the day is gradually reduced; then, following a phase of constant day length, lighting is gradually increased to stimulate the onset of lay. The so called “step down” procedure in the early days of the chick’s life can be used to make the pullets more sensitive to light. After reaching a day length of 10 to 8 hours, the birds are kept for some weeks on constant day length. Although the light hours during this period affect the shape of the step-down and the following stepup procedure, it is of minor importance for the sensitivity of pullets to changing day length. The more time the birds have during this constant phase, the more they will eat and grow. In case of difficulties to reach the target frame size of the pullets and target body weights, a longer constant day can help. Any step-up procedure or increase in day length from an age of 14 to 15 weeks will stimulate the birds’ sexual maturation. A quick step-up procedure will induce an early onset of egg production with high egg numbers and slightly lower egg weights. A slow step-up will delay the onset of lay and increase egg weight. The combination of the quick step-down and quick stepup procedure is recommended for early production and, vice versa, a slow step-down and slow stepup will delay it. If you want early egg production, high egg number and moderate egg weight, use the quick step-down / step-up variant; for larger egg size at the expense of numbers, a slow step-down / step-up variant should be chosen. Since hatching eggs have to be of a reasonable size, parent flocks should never get a quick step-up / step-down procedure.

To overcome the mentioned difficulties with young layers not consuming enough feed shortly before and during onset of lay, it is recommended to increase light by two hours when starting the step-up phase to give them two more hours to eat. For open housing conditions the lighting programs have to be adjusted to the season and the location where flocks are raised and kept for egg production. Recommendations are given by Thiele (2011).

Feeding and adjusting the nutrient intake in lay

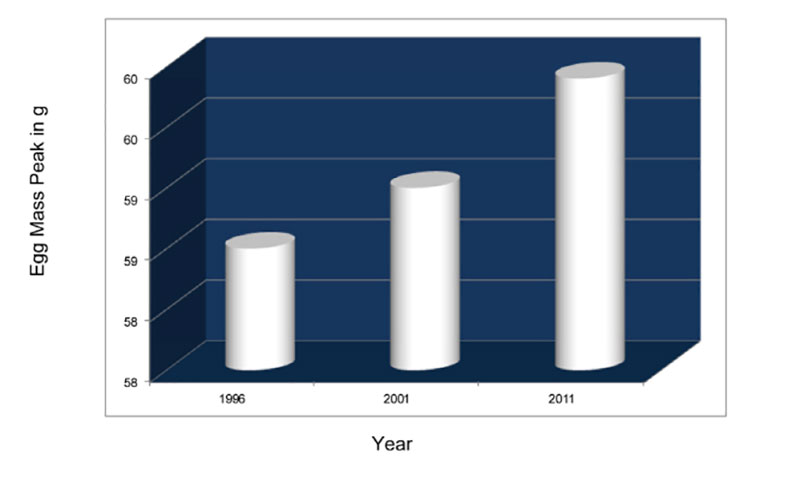

Nutritionists are experts at formulating optimal diets for the changing needs of modern commercial layers, taking the genetic potential for egg numbers and egg weight, market preferences for different egg grades and the cost of available feed components into account. The computer program assures that adequate contents for energy, calcium, available phosphorus, sodium, chloride and choline, digestible lysine, arginine, methionine, methionine plus cysteine, tryptophan, threonine, isoleucine and valine are used for feed production. In practice, all diets have to be adjusted to the actual or expected daily egg mass production of a flock as well as daily feed intake. This requires fine-tuned phase feeding programs with at least three or more phases directed to a specific production profile (egg numbers and egg weight) to avoid wastage of expensive components and minimize feed cost. The genetic potential of commercial layers continues to increase and is much higher today than a few decades ago, especially at peak production. This offers a challenge for farm managers and nutritionists to fully utilize the potential.Sufficient nutrient intake at peak daily egg mass production is of utmost importance. Otherwise, laying hens will run into a nutrient deficiency and will not be able to utilise their full genetic potential. Neither egg number nor egg weight will reach the breeders’ standard. High density layer diets will help to overcome this situation, but needs to be combined with adequate appetite.

Bodyweight development, early egg weight and hen day production in this period will tell a farm manager whether his birds are getting enough nutrients from a balanced diet. If they don’t, a plateau in bodyweight development can be observed and egg weights will remain below the standard. Individual hens may struggle to get into full production and run into health and behaviour problems.

Figure 3: Standard for peak egg mass production of LSL Classic Layers (Management Guides,

Lohmann Tierzucht, 1996; 2001; 2011)

Figure 4: Bodyweight development of LSL Classic pullets up to 40 weeks

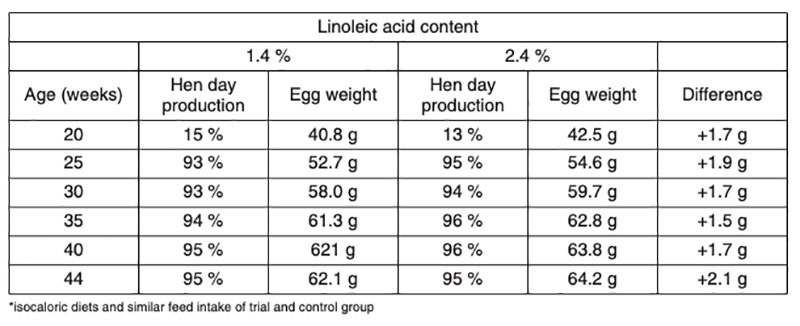

By about 30 to 35 weeks of age, all hens should have learned to eat enough, and insufficient nutrient intake is less frequent. From this time onwards fine-tuned phase feeding programs are the main tool to maintain high egg production at minimal feed cost. Nutritionists can help to achieve the desired egg weight development with feed ingredients, especially the sulphur amino acids and linoleic acid content of a diet.

Table 4: Influence of linoleic acid on egg weight of LSL Classic layers fed diets* with different

linoleic acid contents (Pottgüter 2008)

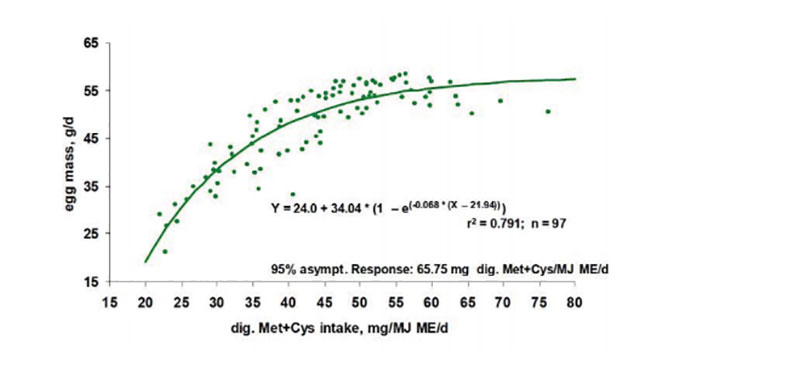

Figure 5: Daily egg mass in 19 experiments plotted against the daily digestible methionine

and cysteine intake standardised to the dietary energy content (Lemme, 2009)

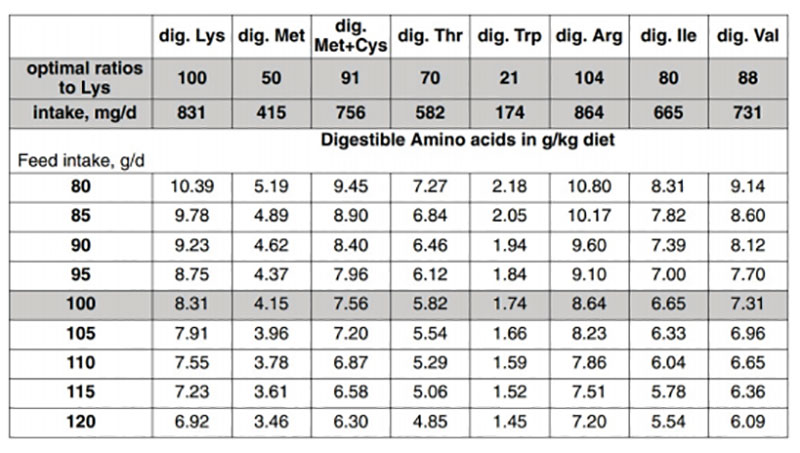

Especially the digestible amino acid profile of layer diet has to be balanced. Recent publications of research results by Joly (2007), Bregendahl et al. (2008) and Lemme (2009) should be consulted regarding the needs of today’s highly productive layers.

The research results of Lemme (2009) are based on trials with Lohmann Brown and LSL layers, and his results were used to update the management recommendations for all commercial layer varieties of Lohmann Tierzucht. For any given daily feed intake, optimal diets can be formulated on this basis. The AA profile is kept constant in all phases, which may not be “optimal” (Elliot, 2012), but is the most practical approach to formulate cost effective layer diets.

Table 5: Recommendations for digestible amino acid intake and diet contents for different

daily feed intake (Dietary energy: 11.82 MJ ME/kg)

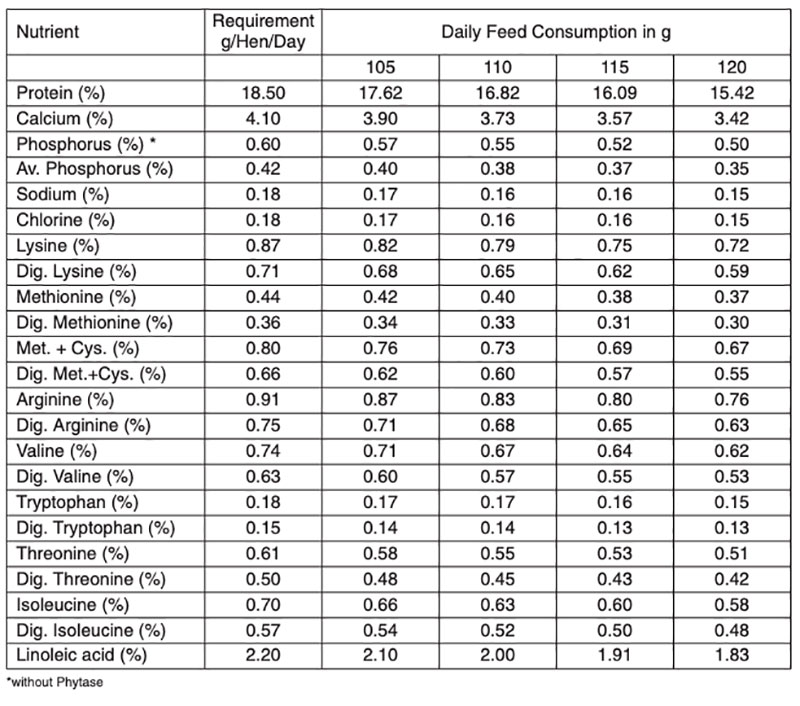

Table 6: Recommended nutrient levels for different daily feed intake in Phase 1:

LSL layers from 19 to 45 weeks of age; above 58.6 g egg mass/hen/day

(Lohmann Tierzucht, 2011)

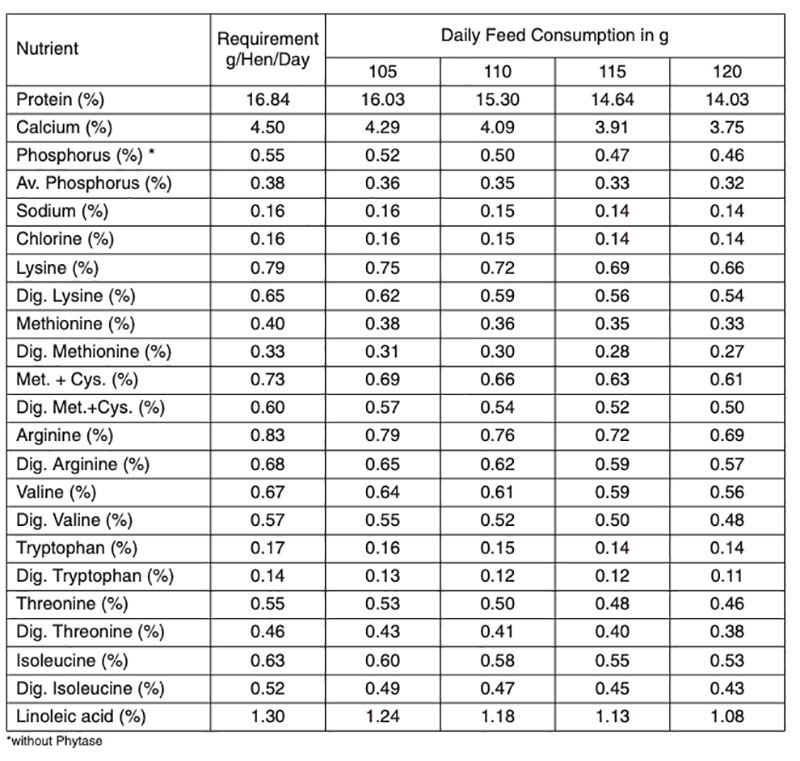

Table 7: Recommended nutrient levels for different daily feed intake in Phase 3,

LSL layers from about 65 weeks of age (Lohmann Tierzucht, 2011)

Reduced digestible amino acids and linoleic acid content, combined with adjusted calcium and phosphorus levels towards the end of production helps to maintain shell stability and limits the increase of egg weight. The optimal age to switch from one phase to the next phase or layer diet depends on daily egg mass production. The most productive flocks will produce on a high daily egg mass level for many weeks. They should not be switched too early to the next diet quality. The maintenance of a desired egg weight profile requires early reaction (Elliot, 2002). Adjusting the feed quality too late will not help to control egg weight.

Egg producers interested in more large and extra-large eggs will switch later to diets containing a lower amino acid and linoleic acid density. They should be aware of the fact that the efficiency of calcium metabolism in the medullary bones declines with age and supply older hens with higher amounts of calcium. Added calcium will have positive effects on shell strength, bone strength, overall health and bird welfare.

Molting

A tool to increase average egg size on a farm is to molt flocks when production and shell quality start to decline. After a pause, hens return to a high level of production and produce mostly large eggs with improved interior quality and stronger shells (Ruzzler, 1996). After a starvation period with substantial weight loss, hens are supplied with a layer diet and will eat enough to regain bodyweight and reach a second peak of production. If a balanced diet is supplied, the healthy appetite of the birds assures sufficient daily nutrient intake to push the egg weight up. In some countries molting is banned due to animal welfare regulations, in others the procedures have been modified to less stressful “non-fast molting programs”. As a result of genetically improved persistency of production and shell strength, molting is losing support in the egg industry. For situations with sufficient rearing space, a longer single cycle is usually more economical than molting. Seasonal fluctuations in egg demand, pullet contracts, cash flow and other short-term arguments may suggest molting to minimize losses rather than maximize farm income.References

Ysilevitz, I. (2007): Pullet and Layer Nutrition, unpublished presentation.Bregendahl, K., S. A. Roberts, B. Kerr, and D. Hoehler (2008): Ideal ratios of isoleucine, methionine, methionine plus cystine, threonine, tryptophan and valine relative to lysine for white Leghorn-type laying hens of twenty-eight to thirty-four weeks of age. Poultry Science 87: 744-758.

Elliot, M.A. (2002): Applied pullet and layer nutrition with an emphasis on problems commonly encountered in the field. Cornell Poultry Pointers, Vol. 52(3): 16-32.

Elliot, M.A (2012): New concepts in layer nutrition. Proceedings of 23rd Annual Australian Poultry Science Symposium, 217-231.

Joly, P. (2007): Re-evaluation of amino acids requirements for laying hens Part 1: Methionine and cystine requirements. ISA Hendrix Genetics: 13.

Lemme, A. (2009): Amino Acid Recommendation for laying hens. Amino News, 13/02: 1-11.

Lohmann Tierzucht GmbH (2011): Management guide layers – LSL Classic.

Pottgüter, R. (2008) personal communication

Preisinger, R. (2002) personal communication

Ruzzler, P.L. (1996): The keys to successful induced molting of Leghorn-type hens. Virginia cooperative extension service, Publication 408-026.

Thiele, H.-H. (2009): Light Stimulation of Commercial Layers. Lohmann Information, 44 (2): 28-37.

Zusammenfassung

Beeinflussung des Eigewichts durch optimiertes HerdenmanagementGenetische und nicht genetische Faktoren beeinflussen das Eigewicht von Legehennen und sollten schon vor Legebeginn durch ein kontrolliertes Herdenmanagement beeinflusst werden. Solche Faktoren sind das genetische Potential einer Herkunft bezüglich ihres Eigewichtes und korrelierenden Merkmalen, das Lichtprogramm während der Aufzucht, die Entwicklung ihres Knochengerüstes und Körpergewichtes. Wenn eine Herde produziert, hat die Nährstoffaufnahme, speziell der Futterverzehr zu Legebeginn, einen großen Einfluss auf die Entwicklung des Eigewichtes. Eine moderne Legehennenfütterung ist darauf ausgerichtet, den Bedarf der Hennen durch Anpassung der Nährstoffzufuhr an die täglich von den Tieren produzierte Eimasse und den Futterverzehr zu decken. Mit einer präzisen Regulierung der Nährstoffaufnahme einer Herde lässt sich kurz- und mittelfristig das Eigewicht beeinflussen. Die Möglichkeit, das Eigewicht durch Mauser einer Herde und ihre Nutzung in einer zweiten oder weiteren Legeperiode zu erhöhen, verliert durch ökonomische und tierschutzrelevante Aspekte an Bedeutung.