Abstract

the performance criteria and carcass characteristic of commonly used duck breed. The results may be used as up-to-date reference values. A total of 2380 ducks of 5 different breeds were raised from day-old to 42 days of age. The birds were fed a 3-phase feeding program.

Body weight and feed consumption were recorded in weekly intervals. Mortality was recorded daily. Samples of all breeds were slaughtered at 36, 40 and 42 days of age. Slaughter weight and percentage of different parts of the carcass were determined. Pooled means

and minimum/maximum values are shown of the present experiment. Data of earlier performance tests (2004 and 2008) are reported to

show the temporal changes. At the end of the test (42 days) live weight was 3.6 kg and feed conversion rate 2.03. The ducks reached 3

kg live weight at 36 days of age, 10 and 8 days earlier than in 2004 and 2008. Daily weight gain was 85 g and feed conversion rate 1.8 kg/

kg. Percentage of the breast including skin increased from 20.7 % at 36 days to 23.8 % at 42 days. The range of minimum and maximum

values was high for all criteria. Mortality from day 7 to 42 was 2.8 %. Compared with data of 2008 there was an annual improvement in

slaughter age of – 0.8 days; in daily weight gain of +1.65 g and feed conversion rate of -0.05 kg feed/kg gain. The European Production

Index (EPI) and Income Over Feed Cost (IOFC) were calculated for 36, 40 and 42 days of age. Higher slaughter age showed positive

economic effects in some lines. The increase in feed conversion rate was obviously balanced by the increased growth rate of the breast

muscle. Range of the means, however increases with slaughter age. Optimum age at slaughter will vary in response of the particular

characteristics of the breed.

Keywords

Pekin ducks, growth rate, feed conversion, slaughter age, slaughter yield, economics

Co-author

K. Damme, J. Hartmann and G. Brehme

Introduction

Planning and calculation of facilities for duck production require reliable basic biological data including growth rate, feed intake, feed conversion rate. These data are also important to appraise the environmental aspects of duck production. The existing data material on duck production is outdated. The last information of the experimental station LVFZ (Lehr-, Versuchs- und Fachzentrum für Geflügel- und Kleintierhaltung, Mainbernheimer Str. 101, 97318 Kitzingen; Germany) on this subject has been published in 2008. There is considerable genetic progress in the performance, feed intake, feed conversion and criteria of the slaughtered birds of commercial duck breeds. It was the objective of the LVFZ to actualize, in cooperation with MEGA animal nutrition and Duck-Tec Hatchery, the above mentioned criteria of five different commercial duck breeds so

as to update the data base for duck producers and governmental authorities.

Birds, material and methods

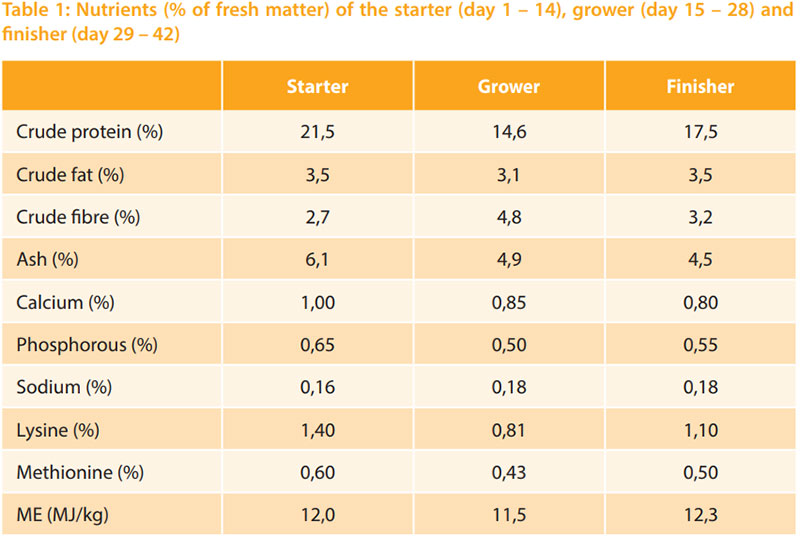

A total of 2380 ducks of 5 different breeds (Cherry Valley, Maple Leaf, Wichmann, Grimaud Frères and Orvira) were used. Dayold ducklings were housed in floor pens on straw as litter. The experimental house was windowless and force-ventilated. Stocking density was 6 birds/m². The birds were fed a 3-phase programme (MEGA Animal Nutrition, 49429 Visbek, Germany) as shown in table 1. Starter was fed from day 0 to 14, grower from day 15 to 28 and finisher from day 29 to 42. Body weight and feed consumption were recorded on day 0, 7, 14, 21, 28, 36, 40 and 42. Mortality was recorded daily. Slaughter yield was determined using samples at 36, 40 and 42 days of age. Slaughter weight and the percentage of valuable parts were recorded. The birds were healthy throughout the experiment and no veterinary intervention was necessary.

Results and Discussion Performance

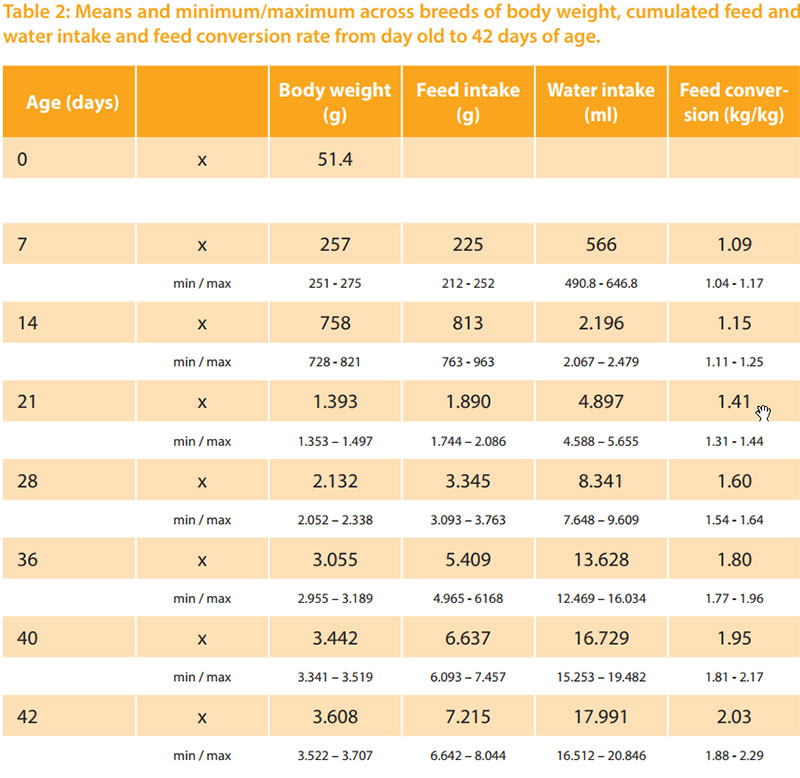

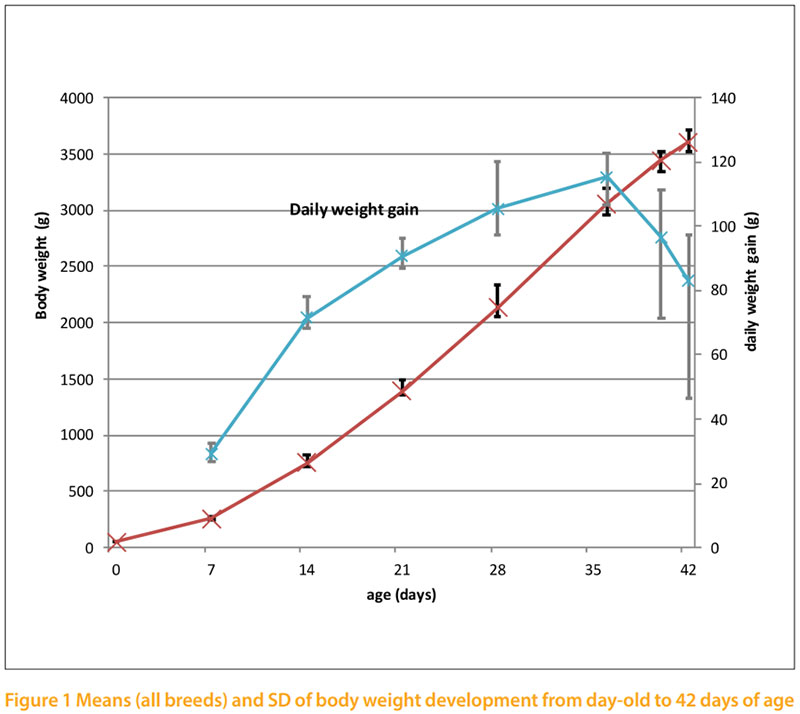

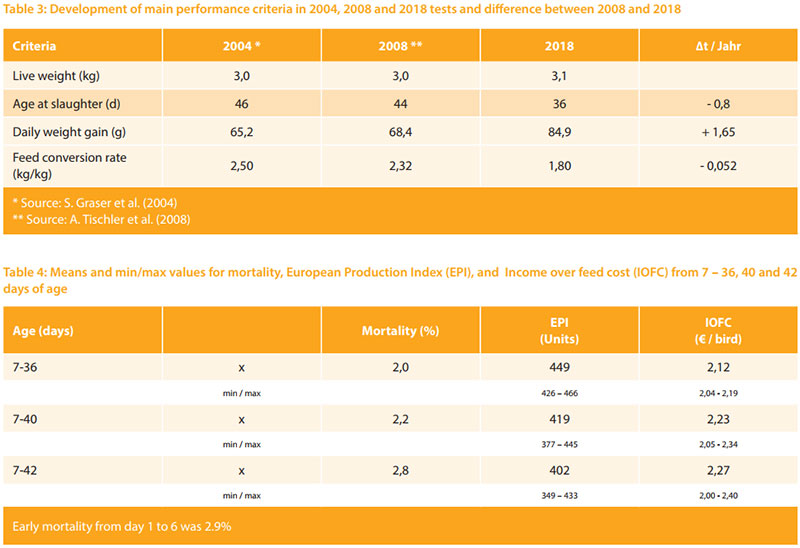

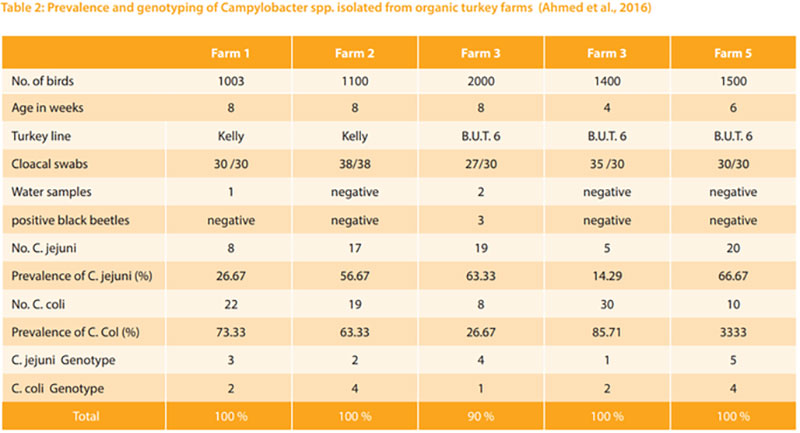

The performance data across the five different breeds are shown in table 2. The development of the main performance criteria from 2004 to 2018 are provided in table 3 for reference. Data from 2008 and 2004 stem from earlier tests under practical conditions and are not directly comparable with the results of the present (2018) station test. The mean daily weight gain and feed conversion rate in 2008 were 68.4 g and 2.32 kg/kg respectively, and in 2004 65.2 g and 2.5 kg/kg resp. The birds reached the slaughter weight of 3.0 kg at 44 days of age in 2008 and at 46 days in 2004. In the present experiment the slaughter weight (3.055 kg) was reached at 36 days of age. Besides the increase of growth rate the feed conversion rate was improved from 2.5 in 2004 to 1.8 in 2018. The annual change during the 10 years from 2008 to 2018 was -0.8 days in slaughter age, +1.65 g in daily weight gain and -0.05 in feed conversion rate. This corresponds to savings of about 150g feed per duck which represents a considerable improvement of the use of resources and reduction of resource based environmental problems. Figure 1 shows the change of body weight and feed conversion rate over the growth period from day-old to 42 days of age. Body weight follows a normal growth curve for ducks with a sharp increase from day 7 onwards (Figure 1). Daily weight gain increased about 27 g at day 7 to 110 g at 35 days of age. Thereafter daily weight gain is falling towards 80 g at 42 days and the Standard Deviation increases considerably. The increased variation in daily weight gain is probably caused by the sex and breed effect which is gaining momentum with increasing age. It has to be mentioned that in the present study the performance results have been produced under standardized conditions of a research station. The feeding program of the present study was not conceived to achieve highest growth rate. Using common commercial duck diets would have given higher growth rates, but on the expense of the bird`s health.

Economics

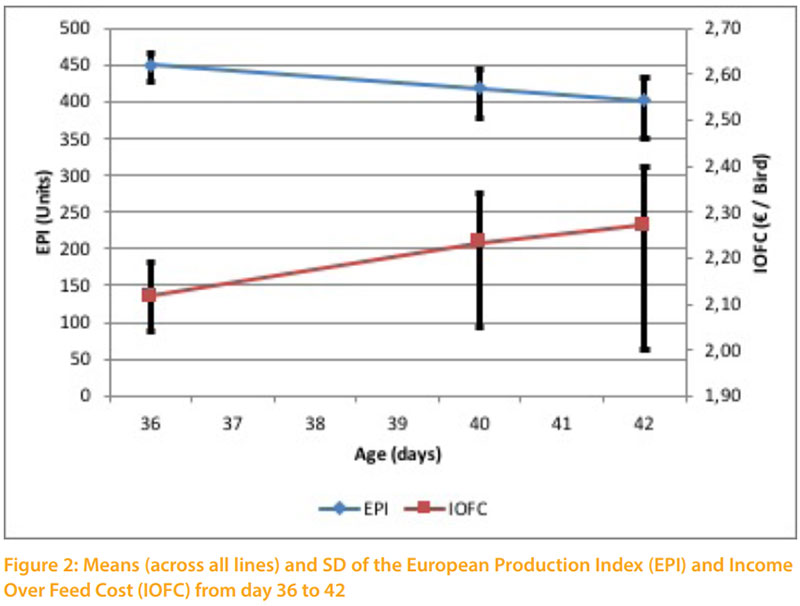

Table 4 shows means and range of mortality, European Production Index (EPI) and Income Over Feed (IOFC) over the growing periods from 7 to 36, 7 to 40 and 7 to 42 days. The EPI is calculated according to the following formula:

The assumed feed price for the calculation of IOFC was 27 €/dt and price for the ducks was 1.17€ per kg live weight. The EPI was nearly 450 from day 7 to 36. This corresponds to the average EPI in broilers. Despite higher growth rate of the ducks from day 36 onwards there is a sharp reduction in mean EPI: 419 and 402 when slaughter age increased to 40 an 42 days (table 4; figure 2). Since mortality was generally low, this is mainly due to the deterioration of feed conversion with increasing age. The high range however shows that there exists potential for further improvement. Some groups showed an EPI which was substantially higher than 450 from day 7 to 36, and of 450 from 7 to 40 days of age. In contrast to EPI the mean IOFC increased from 36 to 42 days of slaughter age. The difference between the minimum and maximum values increases with from 0.15 to 0.29 and 0.40 € as slaughter age increased from 36 to 40 and 42 days. The development of the minimum and maximum values shows that the increase in IOFC with increasing slaughter age is mainly supported by the groups of maximum economic result. The minimum values show a small negative trend in response to slaughter age.

Slaughter yield

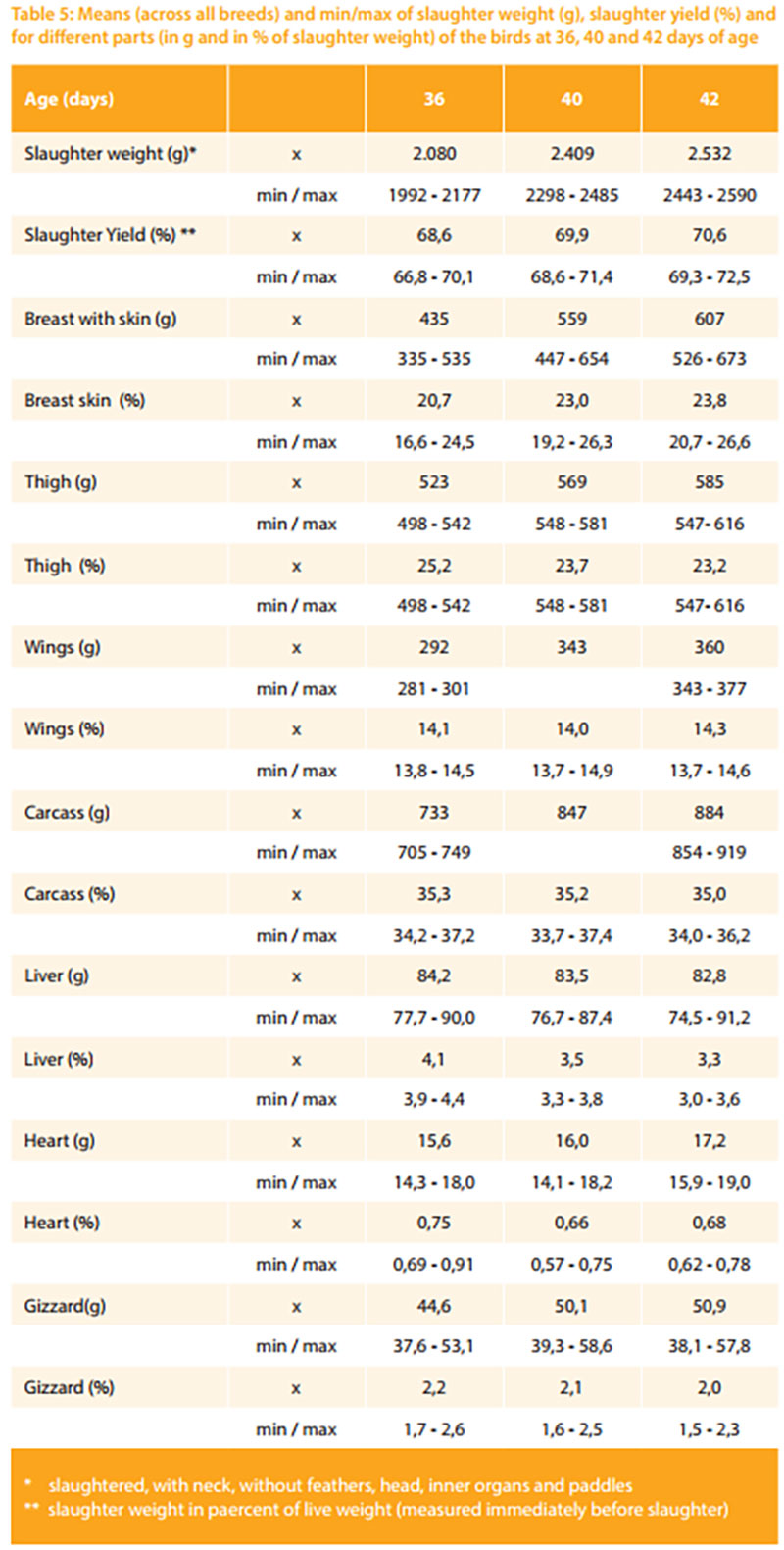

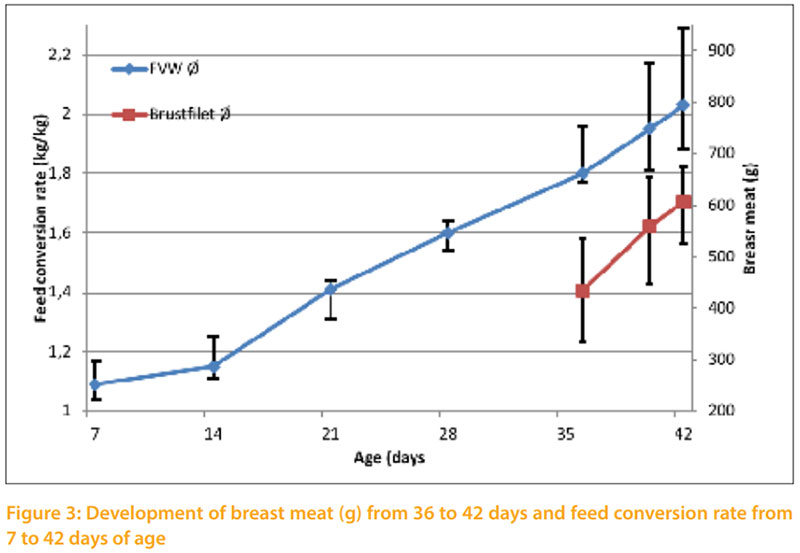

Criteria of the slaughtered birds in response to increased slaughter age are shown in table 5. Mean slaughter weight increased in response to slaughter age from 2080 to 2409 and 2532 g. The difference between minimum and maximum values decreased with slaughter age. Slaughter yield increased with slaughter age from 68.6 to 70.6 %. The improvement in slaughter yield was mainly supported by the increase of the valuable cuts. From slaughter age 36 to 42 days the weight of breast with skin increased from 435 (20.7%) to 607 g (23.8%). Here again there exist extremely high differences between the minimum and maximum values, from 16.6 to 24.5 % at 36 days and 20.7 to 26.6 % at 42 days. The breast meat yield from day 36 to 42 is plotted against the feed conversion rate in figure 3. The increase of breast meat yield from day 36 to 42 is higher than the decrease in overall feed conversion. This leads to an improvement of the feed efficiency related to breast meat yield. 12.7 kg of feed is required to produce one kg of breast meat at day 36. This ratio is reduced to 12.0 kg at day 42. Breast meat is of particular importance as the demand for this valuable part is increasing among the consumers in Europe. As shown in figure 3 the development of the breast muscle starts relatively late in the growing period. It is therefore advised to consider this when formulating the finisher diet. In contrast to broiler, the level of crude protein in the finisher diet of ducks has to be increased at the end of the growing period so as to allow optimum growth of breast meat.

The percentage of other parts did not show great changes with increasing slaughter age. There are tendencies of relative decrease for thigh, liver, heart and gizzard.

Conclusions

The present data provide information on the state of productivity of the actual commercial duck breeds. The results of a performance test of 5 different breeds show a considerable progress in body weight gain, feed conversion rate, slaughter yield and breast meat yield, when compared with data from earlier tests. There exists a high variation among breeds. Consequently the most economic age of slaughter may vary depending on growth rate and breast meat yield. Under practical conditions other aspects, such as feather cover and its influence of plucking, health and mortality have also to be considered.

References

Graser S. et al. (2004): LfL Schriftenreihe 5 –

2004, Perspektiven und Möglichkeiten der

Geflügelfleischproduktion in Bayern.

Tischler A. et al. (2008): LfL Schriftenreihe

13 – 2008, Perspektiven der integrierten

Hähnchen-, Puten- und Pekingentenproduktion in Bayern.