Introduction

Introduction SPF-eggs are used for the production and control of vaccines for humans and animals. This presentation describes the major areas in which embryonated SPF-eggs are used. Furthermore, the advantages and disadvantages of using these eggs in production and control of vaccines will be discussed in comparison to conventional eggs on the one hand and cell lines which are derived from SPF-eggs on the other hand. The following remarks will concentrate on the production and control of viral vaccines for poultry.What is SPF?

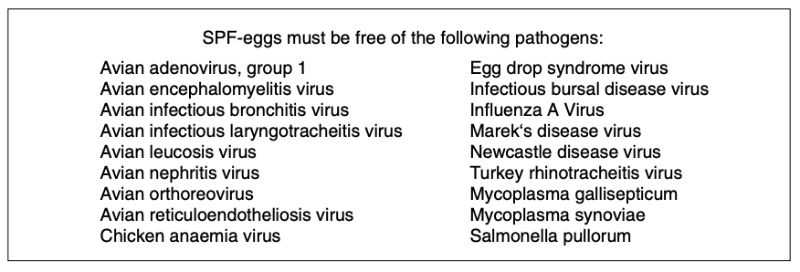

First of all, it should be made clear what SPF means. SPF is the abbreviation of specified-pathogenfree. That means that SPF-flocks for the production of SPF-eggs are free from specific undesirable microorganisms. The antigens not accepted under SPF conditions as defined in the European Pharmacopoeia (Ph. Eur.), 6th edition are shown in Table 1.Table 1: Current requirements for SPF eggs

This list is updated whenever necessary. The actual list can be found in the current edition of the Ph. Eur.. It should be noted that chickens and eggs derived from SPF-flocks are free of the antigens listed; but that does not mean they are sterile. Everybody who uses chickens and eggs for manufacture, control and possibly research should bear this fact in mind, as the “substrates” derived from eggs and chickens may be contaminated by other antigens as those for which the source flocks are tested. This bio-burden may influence the quality of the vaccines and the control tests.

Virus Production

Three kinds of “substrate” derived from SPF-eggs are used for virus production: Embryonated and pre-incubated SPF-eggs, primary cells (e.g. chicken embryo fibroblasts) derived from pre-incubated embryonated SPF-eggs and chickens hatched from SPF-eggs.Virus production in embryonated SPF-eggs has certain benefits compared to the production in cell lines: No additional culture medium is needed. Consequently, there is no risk of contamination with extraneous agents derived from media composed of substances of animal origin. As some extraneous agents cannot be excluded by specific tests (e.g. TSE) this benefit cannot be underestimated.

The harvest of fluids or embryos from incubated eggs can be processed directly. No additional manipulation such as trypsination and washing is necessary.

The purification step can be very simple if the allantoic fluid is harvested and processed directly as it is usually done for most of the avian viral vaccines. The purification procedure used in the production of human influenza is quite the opposite. Here, an intensive purification via different techniques is used (filtration, centrifugation, chromatography). The reasons for these differences are obvious: since purification is costly, purification of harvest material is seldom performed where low priced mass vaccination is needed (e.g. for poultry). Vaccines for other species, where local and systemic reactions against egg material have to be minimized, require purification. For poultry, most of the egg derived vaccines are administered via non-parenteral routes, which leads to less side effects than injection of the same non-purified material may cause.

It should not be forgotten that a prerequisite to virus production is that the virus is adapted to eggs. The harvest and purification of virus harvests requires manpower and special equipment even if some harvest steps can be automated. Negative impact from viral vaccines produced in eggs is derived from the bio-burden. As already mentioned, eggs, especially SPF-eggs, are free from a number of specified pathogens but not sterile. Some production procedures can help to ensure that the level of bio-burden can be kept as low as possible: disinfection of the egg shells, candling of eggs and discarding infertile eggs and eggs with dead embryos prior to harvesting, collecting of harvests in small vessels, discarding parts of the harvests which are too heavily contaminated, centrifugation, etc..

Virus production in primary cells derived from embryos has its advantages when viruses are adapted to cell cultures. One of these advantages is the easy access to a large number of cells without long term pre-culturing, splitting and maintenance as required by permanent cell cultures. On the other hand, the embryonated eggs have to be pre-incubated and the preparation of the cells requires more manpower than the propagation of cell lines. The harvest technique requires some knowhow but is easy in principle. It depends on the type of virus release, i.e. if the supernatant of the cells should be harvested or the cells themselves. Concerning further processing of the harvests, the procedures are similar to those used for virus harvests derived from embryonated eggs. Depending on the route of administration and the species to be vaccinated, the degree of purification is adapted to the final use of the vaccine.

Virus production in chickens is only used in exceptional cases, whenever the virus cannot be adapted to eggs or cells. As far as possible, this sort of virus propagation is avoided for a number of reasons: The maintenance of the chickens is demanding as the animals must be kept in isolators and the harvest requires killing of the chickens followed by a labour intensive extraction of organs. Positive aspects are the easy growth of the virus and the lack of media containing ingredients of animal origin. On the other hand, the bio-burden can be high and may require purification steps during production. Last but not least, the animal welfare aspect has to be mentioned which restricts the use of animals for virus propagation to an inevitable minimum.

Control or Testing of Vaccines

The “substrates” used for the control of vaccines (starting materials, in process controls and final product testing) are the same as for virus production: embryonated eggs, primary cell cultures derived from embryonated SPF-eggs and SPF-chickens.For testing purposes it is inevitable to use SPF-eggs in order to avoid falsification of test results by contamination with other antigens.

As regards benefits and restrictions, testing in embryonated SPF-eggs is in some aspects similar to the virus production in eggs. Some additional aspects should be considered: Tests have to be validated according to Good Manufacturing Practise (GMP), Good Laboratory Practise (GLP) or Quality Management (QM), depending on which laboratory is performing the tests. In any case, it must be demonstrated that the tests are reproducible. As eggs are much more complicated in their structure than cell cultures, validation principles of tests performed in eggs rely more on the principles used for the validation of in vivo tests than validation of in vitro tests.

The necessary equipment for the maintenance of the eggs such as incubators, the logistics concerning delivery/ transport quality, pre-incubation conditions, etc. require special knowledge and manpower. Furthermore, the individual variety of eggs (form, air chamber, size) creates additional obstacles for reproducible and robust testing. Embryonated SPF-eggs are mainly used for titration of live virus and testing for extraneous agents. In very rare cases, serum neutralisation tests are performed in eggs.

Testing in primary cells (Chicken Embryo Fibroblasts, CEF or Chicken Embryo Kidney Cells, CEN) resembles the procedures for virus production. Special attention should be paid to possible contamination of cells during extraction from the embryos. The validation of tests performed in cells follows the principle of in vitro tests. Primary cells derived from embryonated SPF-eggs are normally used for virus titration, testing for extraneous agents and serum neutralisation tests.

Testing in chickens is required for quality, safety and efficacy testing of vaccines. For quality purposes chickens are used for testing of extraneous agents. Strong efforts are currently made to replace these tests by in vitro tests. SPF-chickens are mainly used in laboratory tests on safety and efficacy. Especially safety and efficacy trials are inevitable in order to define the behaviour of the vaccine in target animals. Concerning validation and organisation of tests, the aspects already mentioned for production and use of eggs apply. For safety tests a number of tests has to be performed (overdose studies, spread of vaccine strain, reversion to virulence, etc.). The efficacy tests consist serological and challenge trials in order to define the onset, level and duration of immunity.

Conclusion

Embryonated SPF-eggs are essential to the production and control of vaccines adapted to eggs. SPF-eggs are also the major source for primary cells or even live chickens. There is no biological substrate which is able to replace SPF-eggs. Even if the resources in personnel, logistics and equipment which are necessary for the use of eggs are demanding, the benefits for safe production and testing outweigh the overall costs of using this live system.European Pharmacopoeia (Ph. Eur.), 01/2008: 50202, 6th Edition, Council of Europe, Strasbourg, France, 2008.

DIRECTIVE 2004/28/EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 31 March 2004 amending Directive 2001/82/EC on the Community code relating to veterinary medicinal products(OJ No L 136 of 30.4.2004 , p. 58).

DIRECTIVE 912/91/EEC Commission Directive of 23 July 1991 laying down the principles and guidelines of good manufacturing practice for veterinary medicinal products, (OJ No L 228 of 17. 8. 1991, p. 70).

The EDQM & Quality Assurance, www.edqm.eu /Quality Assurance Policy

Zusammenfassung

Die Bedeutung von SPF-Eiern für die Herstellung von Geflügelimpfstoffen und die routinemäßige QualitätskontrolleVorgebrütete SPF-Eier werden für die Produktion von Geflügelimpfstoffen und deren Überwachung gebraucht. Aus SPF-Eiern werden auch Primärzellen und lebende Küken produziert. Einen biologisches Substrat, das SPF-Eier ersetzen könnte, gibt es nicht. Der Kostenaufwand für Personal, Logistik und Material für die Produktion von SPF-Eiern ist beträchtlich, aber die Vorteile für die Qualitätssicherung von Impfstoffen und Laborergebnissen rechtfertigen den hohen Aufwand.