Abstract

Environmental temperatures play a major role in the optimal rearing of layer pullets, the basis of a financially successful production period of the layer bird. The optimal temperature for a white layer is 23 degrees celcius, respectively 24 degrees for brown layers. Every degree Celsius above this level will cause reduced feed intake and as a result a decrease in egg numbers, shell quality and egg size. This problem can easiest be solved by housing the birds in an environmentally controlled house with optimal temperature. Due to lack of infrastructure such as electricity or financial means many farmers in hot climates cannot provide such a solution and need to rely on feeding techniques and special feed formulations, light programs such as midnight snack as well as water quality and temperature to achieve a satisfying production. Feeding techniques help the bird to eat at optimal times during the day, feed formulations ensure that the hens are supplied with all required nutrient, Midnight snack provide extra time for feeding during the coolest period of the day and optimal water temperatures ensure the birds are able to reduce their body temperatures and maintain their appetite.

Keywords

Laying hens, pullets, feeding, management, climatic conditions

Introduction

Chickens originated from the jungles of Southeast Asia some 10,000 years ago, and the earliest known domestication occurred in Northern China 8,000 B.C. as determined from archaeological chicken bones (Lawler, 2015). From here poultry production has spread worldwide with the first industrialization in the Northern hemisphere with cool and moderate climates. Nowadays the industry is continuously navigating back again to Asia and the Southern part of the world as a result of increasing population in Asia, Africa and South America in combination with declining birthrates as well as strict animal right laws in Western countries. Asia today accounts for 54.6% of the world poultry population, followed by the American continent with 26% and Africa with 8.2%. This means the production of poultry meat and eggs is in hot climates.

In order to facilitate cost effective egg production in these challenging environments, special management strategies have to be applied. Poultry scientists have reported results of their own experiments and reviewed the available literature during the last decades which help to understand the needs of hens under heat challenge. This article is focused on the application of these results in practice.

Sufficient body weight at onset of lay

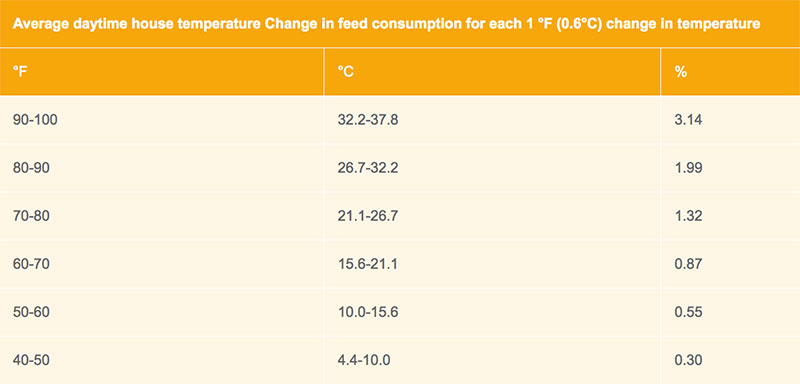

The basis of good egg production is a successful rearing phase, at the end of which the hen should have reached her standard body weight, with a well-developed frame and corresponding appetite or feed intake capacity. Already about 50 years ago, Payne (1966) compared pullets reared from 6 to 21 weeks of age in environments of 20°C vs. 33°C. The birds reared at 33°C were 118g lighter at 21 weeks of age and their eggs consistently smaller throughout the laying period than the group reared at 20°C. The response of feed consumption to increasing ambient temperature and its effect on later performance is shown in table 1 and 2. Pullet body weight plays an important role in egg production, and I recommend to target 10% higher body weight in hot climates than the weight standards published by primary breeders for moderate climates. Heavier hens will consume more feed which will result in higher peaks, better persistency and better resistance to heat stress and diseases. Twelve week weights are reliable predictors of 20 weeks weights, that is: pullets that are below breed standard at 12 weeks of age will remain low at 20 weeks, whereas a pullet which is heavy in 12 weeks of age will be heavy at 20 weeks of age. Therefore special attention should be focused on pullet weight development to 12 weeks of age.

Table 1: Decrease of daily feed consumption of growing pullets with increasing house temperature.

Source: Bell and Weaver (2002)

I have found it useful and strongly recommend to separate the birds into 2-3 groups on bodyweight as early as possible and then adjust the feed composition/phasing accordingly so that underweight birds have a better chance to catch up in their development before sexual maturity. The first 8 weeks are critical for the skeleton development of the bird and therefore the base of a well developed hen. Smaller birds will have the chance of growing according to the standard without having to compete with larger and more dominant birds resulting in a more uniform flock in production. Later in the phase of 9-16 weeks the hen can be trained in high feed intake capacity due to the less dense developer feed without risking of running into problems with bodyweights at end of rearing. Transfer to the laying house (with higher light intensity!) can then also be organized stepwise according to development. This will help to minimize the risk of prolaps and cannibalism due to overstimulation of underweight pullets.

Additional space to minimize heat stress

If the birds are placed in naturally ventilated houses, it is better to start with 10% fewer chicks for a given space than during normal temperature conditions. This will give the chicks more floor space and better ventilation between the chicks as well as more water and feed space. Increased density of hens in cage or on floor increases effects of heat stress, i.e. reduced egg production due to reduced feed intake, increased feed requirement due to heat stress and increased mortality. Researchers at North Carolina State University recommend 460 cm² per bird in hot climates in fan ventilated houses and even more space when only natural ventilation is available. Adams and Craig (1984) compared feed intake and egg production at densities of 516, 378 and 310 cm² per bird in conventional laying cages. Increasing space from 310 to 378 cm² per bird resulted in 16.6 more eggs per bird for the cost of 1.9 g feed/hen/day. Increasing space from 387 to 516 cm² resulted in 7.8 more eggs/hen housed, 4.3 g per hen/day higher feed consumption and 2.8% lower mortality.When day-old chicks are housed in floor systems, plastic foils or paper will help them to find feed and water. In cage systems, extra light directly in the cages as LED tubes (like those used for Christmas decoration) will help the chicks to find water and feed quickly.

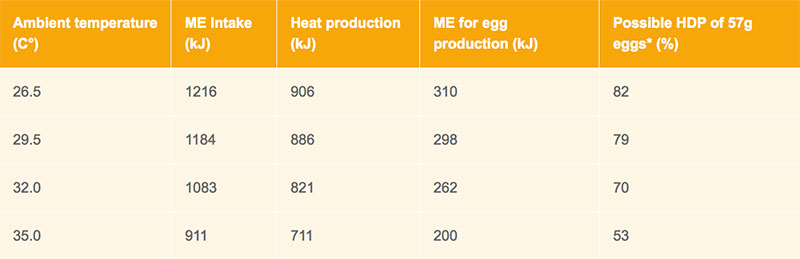

It is absolutely essential that the chicks reach their normal body temperature of 40-41°C as fast as possible after housing. Ideally, this should be checked with an ear thermometer a couple of hours after placement. If the body temperature is below 40°C, the house temperature has to be increased by all means. Make sure that the air humidity does not drop below 70% as a result of heating. The effect of ambient temperature on feed intake of laying hens (in ME), heat production and availability of ME for egg production is illustrated in table 2.

Table 2: Decrease of feed intake with increasing house temperature and availability of ME for egg production. Source: Smith and Oliver (1972), cited by Balnave and Brake (2005)

* Assuming 376 kJ of ME per egg.

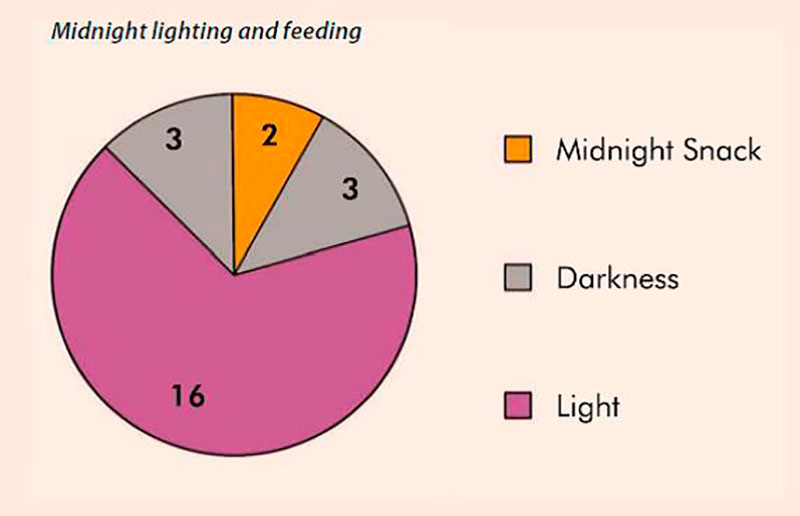

Lighting Program

Starting chicks on a lighting program with 4 hours light and 2 hours darkness alternating has shown improved uniformity and reduced mortality compared to conventional lighting with 16 hours light and 8 hours darkness. This program can be used for the first 10 days and then changed to conventional lighting programs as recommended by the breeder, possibly with a “midnight flash” to stimulate additional activity and feed intake. Leeson, Caston and Summers (2003) conducted tests in which growing pullets received different midnight light treatments, one group grown in 8 h of light, the other in 12 h of light. The groups given a midnight light of 2 hours from 0-18 or 4-18 weeks produced the highest number of eggs to 70 weeks of age. But introducing a midnight flash late in the rearing period, after 12 weeks of age, resulted in pre-mature onset of lay, with the well-known risks of prolapse, cannibalism and negative effects on persistency of egg production. Practical experience, especially with Leghorns, indicates that 1 to 1.5 h light around midnight has positive effects on feed intake and weight gain (figure 1). Extra lighting around midnight (Fig. 1) has the advantage of giving the birds additional feeding time during cooler parts of the night and does not disturb the lighting program, as long as at least 3 hours of darkness are provided before and after the extra light period. A similar program can be used during the laying period.

Fig. 1: Midnight snack: lighting during cool hours of the night to stimulate additional feed intake. Source: Lohmann Tierzucht Management Guide

Heat production of the body is higher during light periods and abdominal temperature declines with reduction of light intensity. Several recommendations for different lighting programs can be found in the literature. Nishibri (1998) recommended a “reversed lighting program”, with light during the cooler time from 6 p.m. to 6 a.m. instead of during the hot hours of the day, when the birds should rest to minimize heat stress. With this program, the hens produced significantly more eggs than with daytime feeding.

To apply this idea under commercial conditions would require investment in light proof houses, and the extra cost and inconvenience for staff working in night shifts as well as energy cost has to be justified by higher egg output and enhanced bird welfare.

Purina Mills Inc. recommended “biomittent” lighting for pullets based on the idea that better body weights can be achieved due to less activity and better feed utilization. The light program is as following: 24hrs light during the 1st week, at 2 weeks of age the light is reduced to 8h daily and from 3-18 weeks lights are maintained at 8hrs daily with an alternating program of 15 min light/45 min darkness, except for the last hour of the day when the light pattern is 15 min light – 30 min dark – 15 min light. Ernst (1987) concluded from his tests that intermittent lighting (2 h dark – 4 h light) for pullets between 2 to 20 weeks show improved weights.

Basically the light program in the rearing should provide the pullets with enough light in order to achieve the target body weight and eating capacities. Heat production of the body increases with feed intake therefore it is recommended to start the lights early in the morning in order to use the cooler parts of the day for feeding and avoid digestion of the feed during the hot daytime. Since light intensity also increases body temperature, the house should be kept as dark as possible to avoid heat stress for the birds.

Water

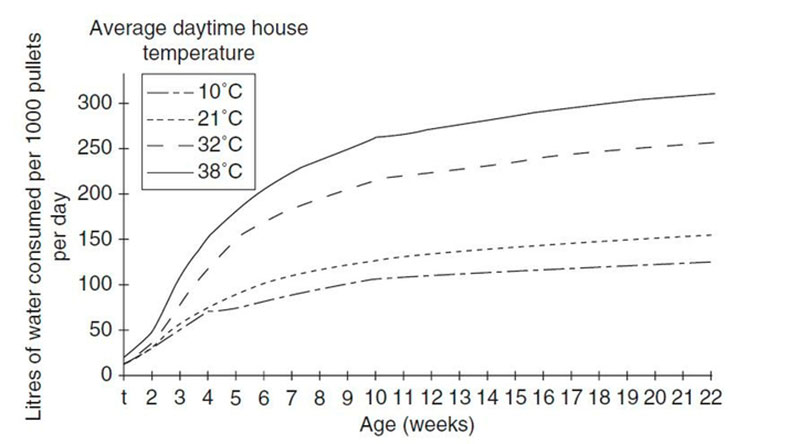

Environmental temperature is the most important factor determining water intake, as illustrated in Fig. 2. Leghorn pullets drink at least twice as much per day at 38°C compared to 21°C house temperature, whilst water temperatures below 21°C do not influence the water intake. Most authors agree that the optimum water temperature is about 23°C. A common challenge in hot climate areas is to provide sufficient drinking water at optimal temperature for all birds at all times. Water intake is the key to good feed intake, especially in hot climates.

Figure 2: Water consumption of growing pullets as a function of house temperature

Source: Daghir (2008)

The water temperature should never exceed body temperature of the birds. Tests have shown that feed intake is reduced if water temperature exceeds 35°C, and drinking water of 35-40°C has significant detrimental effects on performance. Therefore the farm management has to do everything possible to offer cool water to birds in rearing as well as in production. Possibilities are plenty, from regularly flushing the water lines or emptying the bell drinkers, insulating water tanks and lines (also in the house) to adding ice cubes into water tanks or even installing chillers for drinking water, depending on the sophistication of the farm.

The water systems should be the same in the rearing and production house to assure that the pullets find water immediately after transfer. If a loss in appetite and feed consumption, perhaps also increased mortality, is observed after transfer, a common reason is that some birds take too long to find water and therefore stop eating. Especially in this stressful transition period the birds need to maintain their appetite in order to cope with the challenge of sexual maturity and first egg production, while continuing to gain body weight. The maximum daily water consumption is at 6-7 weeks of production which is also peak production. Stress can increase vitamin needs in hot climates, especially A, C and E. In hot and humid areas vitamin stability is reduced, therefore it is a good practice to offer vitamins in drinking water 3 days before moving the birds and electrolytes for another 3 days after the move. Pullets should not be serviced or moved in the hot part of the day, preferably at night; 30% less pullets per crate than recommended for cool days should be placed for the transport. In-line filters should be checked and cleaned on a regular basis and replaced often. Functional pressure gauges on both sides of the filter are an advantage and a 3-8 lb differential between incoming and outgoing water pressure should be maintained. The water pressure at the end of the line has to be checked daily to assure that also the hens at the end of the building receive sufficient water.

Underground water supplies are very common in many countries in the hot regions of the world. Well water often has inferior quality compared to city water and can have negative effects on the performance of growing pullets and laying hens. Therefore well water must be checked regularly in a competent laboratory for bacteria and internal quality. Saline water may be a contributing factor if shell quality, especially of older hens, persistency of egg performance, feed intake and/or egg weight are below the breeder’s standard. In this case the feed formulation must be adjusted, with a lower salt level in the feed according to the saline level of the water.

Different additives in water have shown positive effects to reduce heat stress of layers. For example birds given carbonated water at times of temperatures around 35°C were able to maintain shell quality much better than the control (Daghir 2008). Vitamin C improves performance in hot weather, with only 100 ppm ascorbic acid. Best results were achieved with protected ascorbic acid (e.g. Cuxavit C50) and the phosphate ester. Flocks receiving extra vitamins and electrolyte water additives during heat periods had a smaller drop in production and recovered sooner. Sodium zeolite in water can also be beneficial in reducing effects of heat stress in layers. Why it is successful is not fully understood; perhaps it acts as a buffer in the gut and reduces alkalosis associated with panting.

Feed intake and adjusted composition

House temperature is the most important factor in feed consumption of layers. Maintenance requirement in Leghorn and Brown birds is reduced by 30 kcal/day when the ambient temperature rises from 21 to 38°C. It reaches a low at 28°C and increases with rising environmental temperature due to the cooling energy required by the hen. Above 28°C feed intake decreases. The average loss in energy intake is 1.6% per 1°C as environmental temperatures increase above 20°C, therefore the bird might easily run into a nutrient deficit resulting in low performance. The maximum energy available for production is at 23°C for brown birds and 24°C for White Leghorns.It is essential to monitor feed consumption on a daily base so energy level as well as feed density can be adjusted to daily feed intake. Alternatively stimulation for feed intake has to be intensified with reduction of energy and density of the feed such as turning of the feed chain or shaking of the feeders can. Tadtiyanant et al. (1991) concluded from several tests with wet feed that birds had 38% more dry matter intake compared with dry feed at 33°C. Sprayers can be installed on top of feed chain or water can be added and mixed with feed manually, depending on the level of the management.

Use of high energy layer rations is recommended in hot climates. Fat adds energy to the diet and stimulates feed intake and therefore ME intake. Many feed mills in hot climates have a problem providing good feed structure and often end up producing fine and dusty feed. Adding oil improves the palatability of the feed and therefore makes it easier for the hen to eat enough. Oil also has less heat increment produced during digestion which reduces the heat stress on the bird. Adding 5% fat does not only improve feed intake but also egg weight and shell thickness. In test conducted in Malaysia it was shown, that when free to choose, hens tend to consume more feed with supplemental fat than oil free feed. Sohail et al. (2002) observed that maximum profits were obtained when fat is added to the highest protein diet (19.8%) from 21 to 37 weeks of age, but special care has to be taken to avoid oxidation.

Feed intake decreases not only when temperatures rise but also when energy is increased in the feed. Peguri and Coon (1991) found that feed intake was 5-9 g lower when ME was increased from 2645 to 2976 kcal/kg and was 217 g lower when temperatures were increased from 16 to 31.1°C. Egg weight increased when feed energy was increased from 2645 to 2976 kcal/kg and decreased when temperatures increased from 16.1 to 31.1°C. More expensive feed can in the end save money due to lower feed quantities.

Protein requirement is not affected by temperature, but it is common knowledge nowadays that protein and amino acid rich diets are essential in hot climates to ensure the same daily intake of these nutrients as would be consumed at 21°C. De Andrande et al. (1977) fed laying hens under heat stress a diet containing 25% more of all nutrients except energy, which was only increased by 10%. He observed that with this kind of feed the hen overcame most of the detrimental effects of high temperature on percentage egg production and egg weight. A daily intake of 360 mg of methionine should be obtained because small eggs can be a result of low energy intake but also low amino acid intake. The decrease of egg weight for every 1°C rise in temperature has been estimated between 0.07 to 0.98 g per egg. Daily linoleic acid intake should be at least 2g per bird, best to be achieved by fat. High temperatures increase respiratory rate, resulting in respiratory alkalosis, which alters acid-base balance and blood pH. Adding sodium bicarbonate to feed and carbonated water can help.

Excessive calcium can have negative effects on feed intake due to physiological effect of appetite and reduced palpability of the feed. Feed intake of laying hens may decrease as a result of excessive levels of fine calcium in the diet. Devegowda (1992) reported that in India feeding calcium separately with a diet of only 2% calcium improves feed intake, egg production and shell quality. Since the calcium requirement of a layer in peak production is about 4.1 g and increases to 4.5 g with age, the missing 1.9-2.2% calcium should be offered ad lib as coarse calcium on top of the feed for cage management or in extra containers for floor and aviary systems, so each hen can consume it according to her needs (table 3). Main demand for calcium is in the afternoon and evening hours. If separate calcium feeding is not possible, at least 50% of the calcium in a ration should be given in coarse particles rather than all the calcium in powder form. This ensures that the calcium is not completely digested before the early hours of the morning when the hen needs it for egg shell production. A ”midnight snack” not only improves feed intake but also reduces stress on the hens due to an extra calcium intake at the time the organism requires the supply.

Table 3: Recommended Structure of Calcium in Different Types of Layer Feed. Source:Lohmann Tierzucht Management Guide

Phase feeding

It is recommended to supply feed twice a day, with 1/3 of the feed in the morning and 2/3 in the afternoon, leaving the feeders empty for max. 1 hour a day during the hottest hours. This stimulates feed intake, ensures that also the fine parts of the feed are consumed and prevents molding of the feed. Pre-layer feed is a must and should be offered 2-3 weeks before egg production when liver and reproductive organs are increasing in size and at the same time calcium reserves are built up to meet demands of shell production. It should be given for about 10 days and not more than 1kg per bird. The hens can get adjusted to the higher amount of calcium of the feed and will not lose their appetite when given layer phase one feed containing normally 3.9% calcium. Early introduction of high calcium levels in layer diets have often shown to increase wet manure, and the use of pre-layer feed should also help to minimize this problem.Studies have shown that laying hens are able to survive heat stress periods better if they have been exposed to a daily, intermittent heat-stress situation. Therefore it may be considered to allow rearing birds to be exposed to temperatures of 29-33°C before laying period even if it would be possible to keep the environmental temperature below this level with the help of the house system. White Leghorns are not necessarily more heat-tolerant than brown strains, as was assumed many years ago. It is recommended not to remove combs and wattles as these organs are used to help cooling the body. Birds can also wet them with the offered drinking water, either in bell drinkers or nipple drinkers which should be equipped with cups.

Wet droppings can be a problem in hot climates due to the increased water intake. Layers drink more in cages than on floor and water intake increases with production. High levels of protein and salt have shown to increase wet droppings. Sodium levels in the diet should be kept at 0.18-0.16 g/day per bird. But also the use of high amount of barley and crumbled feed might cause wet droppings.

Field results in Tanzania

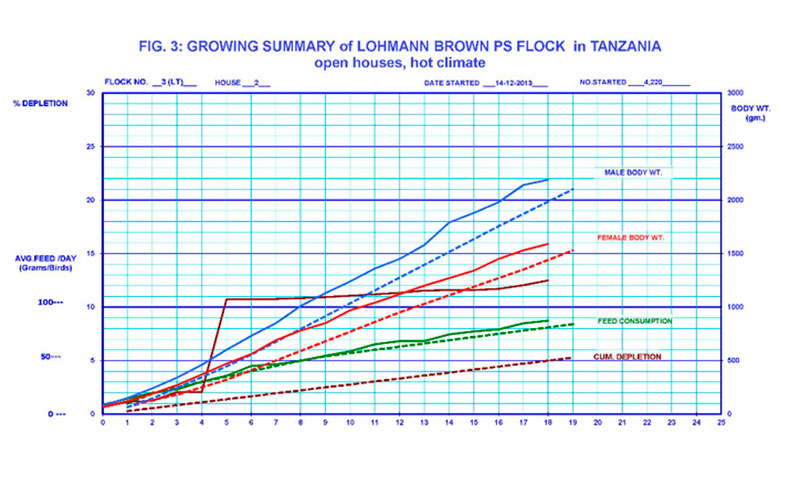

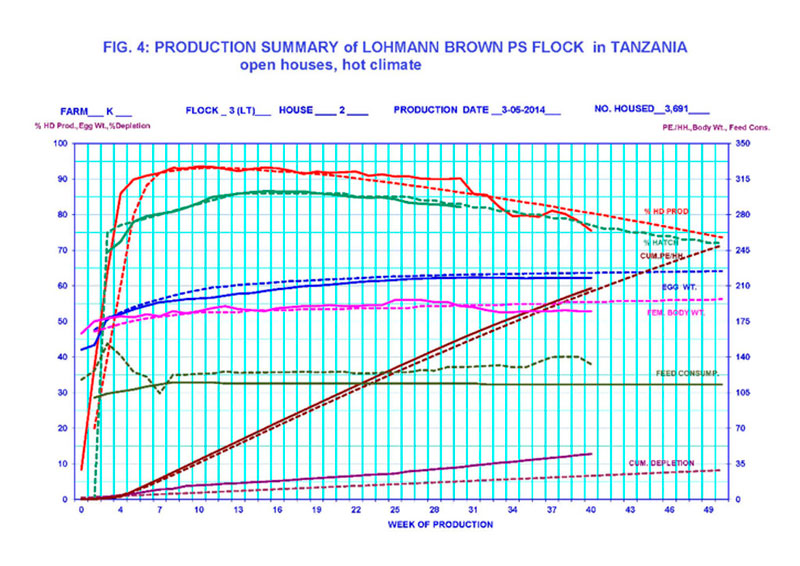

Paying special attention to the needs of the birds in hot climates pays off, as illustrated in figures 3 and 4. This brown-egg parent flock suffered from a bacterial infection at 3-4 weeks of age, which unfortunately is not infrequent in open houses. However, after treatment the survivors developed well, perhaps benefited from the lower density and performed similar as would be expected in moderate climates. Obviously commercial chickens and parent stock of modern strains are adaptable to tropical climate and can cope well with conditions in open houses with only natural ventilation, at temperatures up to 40°C and a humidity of 60-70%.

Fig 3: Growing summary of LB PS Flock in Tanzania

Figure 4: Production Summary of LB PS Flock in Tanzania

Summary and conclusions

Egg production in hot climates is a challenge for every producer, but excellent results can be achieved without investing in expensive environment control, if good management is applied throughout the life of a flock, based on the results of poultry research and experience in practice. Layers in hot climates need more space in rearing and in production. Different light programs can help to achieve the standard body weight even in heat stress. A midnight snack enables the birds to consume feed in the cool parts of the day and will provide them with calcium for the shell production in the early morning hours. Feeding coarse calcium separately to a low calcium feed will increase the feed intake and also will reduce the risk of early mortality due to cage layer fatigue. Cool water will allow the hens to reduce their body temperature and maintain their appetite. Adding oil and fat to the feed will make it more palatable and therefore easier to consume as well as provide the correct amount of energy even with reduced feed intake. Hens like humid feed, wetting the feed will help to increase feed intake in hot climates. Birds can get adjusted to hot climates and can be trained via intermittent hot periods in the rearing to withstand heat stress better during rearing.References

Adams, A.W. and Craig J.V. (1984) Effects of crowding and cage shape on productivity and profitability of caged layers: a survey. Poultry Science 52: 1221-1225.Balnave, D. and J. Brake (2005) Nutrition and management of heat-stressed pullets and laying hens. World Poultry Sci. Jour. 61: 399-406.

Bell, D.D. and W.D. Weaver, Jr. (2002) Commercial Chicken Meat and Egg Production. 5th Edition. Kluwer Academic Publishers.

Daghir, N. J. (2008) Replacement pullet and layer feeding and management in hot climates. In: Poultry Production in Hot Climates, Second Edition: 261-293.

De Andrade, A.N., J.C., Rogler, W.R. Featherston and C.W. Alliston (1977) Interrelationships between diet and elevated temperatures (cyclic and constant) on egg production and shell quality. Poultry Science 56: 1178-1188.

Devegowda, G. (1992) Feeding and feed formulations in hot climates for layers. Proc. 19th World’s Poultry Congress, Amsterdam, NL. Vol. 2: 77-80.

Ernst, R.A., J.R. Millan, and F.B. Mather (1987), Review of life history lighting programs for commercial layer fowls. World’s Poultry Science Journal 43: 43-55.

Escalante, R., I. Chernova, J.A. Hererra and Exposito (1988) Effects of body weight at 18 weeks of age on the lifetime performance of Leghorn pullets. Revista Cubana de Ciencia Avicola.

Lawler, Andrew (2015) Why did the Chicken Cross the World? Duckworth Overlook.

Leeson, S., L.J. Caston and J.D. Summers (2003a) Potential for midnight lighting to influence development of growing

Leghorn pullets. J. Appl. Poult. Res. 12: 306-312. Leeson, S., L.J. Caston and J.D. Summers (2003b) Performance of layers given two-hour midnight lighting as growing pullets. J. Appl. Poult. Res. 12: 312-320.

Nishibri (1998) Diurnal variation in heat production, heart rate , respiratory rate and body temperature of laying hens at constant environmental temperatures of 23°C and 35°C. Jap. Jour. Zootechn. Sci. 60: 529-533.

Payne C.G. (1966) Environmental temperatures and the performance of light breed pullets. Proc. 13th World’s Poultry Congress, pp 480-484.

Peguri and Coon (1991): Effect of temperature and dietary energy on layer performance. Poultry Science 70,

Sohail, S.S., M.M. Bryant, and D.A. Roland (2002) Effect of energy and different energy levels on egg weight of older hens under summer conditions. Poultry Science Poscal 80: 120-?

Tadtiyanant, C., J.J. Lyons, and J.M. Vandepopoliere (1991) Influence of wet and dry feed on laying hens under heat stress, Poultry Science 70: 44-52.

Thiele, H.-H., G. Díaz and L. Armel Ramirez (2015) Optimal calcium supply of laying hens. Lohmann Information 49(2).