Summary

The global animal industry is facing severe economic pressure due to high prices of feed ingredients.

The producers must push to make maximal use of the feed. In several markets, producers are heavily

pressured to reduce the use of antibiotics and are facing increasing consumer demands for high

quality, safe, welfare-friendly meat. These challenges force every link in the production chain to retune

how we rear animals in terms of nutrition, management and product use. The present paper summarizes approaches to fine-tune the nutritional concept. Dietary specifications have to be reevaluated

and phase feeding concepts optimized in order to maximize margin over feeding cost. If alternative ingredients are available at the right price they offer an interesting approach to reduce feeding cost.

However, particularly when using alternative ingredients and reducing the dependency on antibiotics, intestinal health must become a key focus. Optimizing protein digestibility can help to minimize the intestinal problems. In addition, mycotoxin contamination must be dealt with and novel feed additives and feed ingredients considered. The entire system must be thoroughly reviewed and existing margins for improvement exploited in all areas of production.

However, particularly when using alternative ingredients and reducing the dependency on antibiotics, intestinal health must become a key focus. Optimizing protein digestibility can help to minimize the intestinal problems. In addition, mycotoxin contamination must be dealt with and novel feed additives and feed ingredients considered. The entire system must be thoroughly reviewed and existing margins for improvement exploited in all areas of production.

Introduction

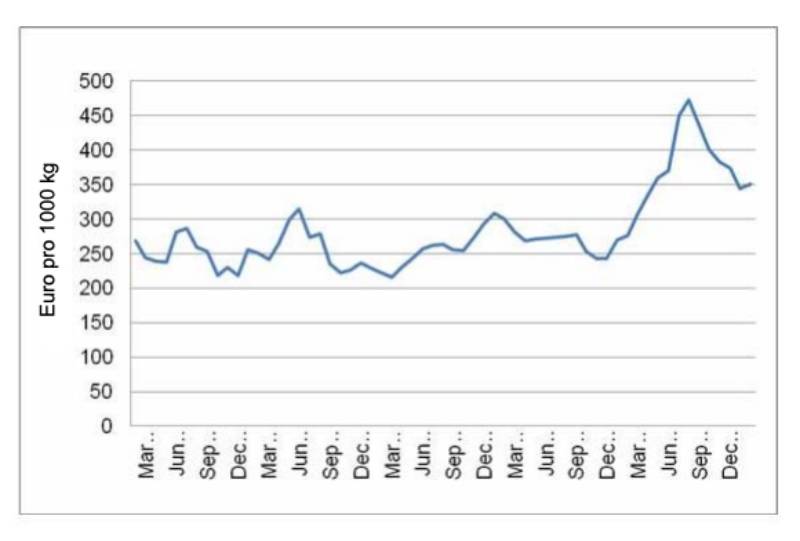

Feed accounts for 50-70% of the total costs in animal production. Any operation must therefore have clear targets how to optimize feed efficiency and reduce feed cost and work daily towards those targets. The sharp rise in feed ingredient prices in general, and soy bean meal in particular (Figure 1), has forced producers to refocus on what they spend on feeding, to raise efficiency targets and to go the extra mile for converting feed protein more efficiently into lean gain. In recent months ingredient prices have softened, easing the pressure somewhat, however, prices are expected to stay high and keep rising in the long term. There is no doubt that extra efforts are needed to optimize the use of feed in order to stay in business for the long run. The European industry, in addition, is heavily pressured to reduce the use of antibiotics and is facing increasing consumer demands for high quality, safe, welfare-friendly meat and eggs. These challenges mean that every link in the production chain has to be retuned regarding how we rear livestock and poultry in terms of nutrition, management and product use, while maintaining the focus on market demands. There is no magic solution to this challenging situation. When talking about sustainability of a production system, ecological and social aspects are major issues. However, in the current market, sustainability of livestock production in Europe is primarily threatened by not achieving the economic results a farm or a production system needs for longer term survival. No single change alone will bring about the improvement in nutritional efficiency needed. It is therefore necessary to reevaluate and fine-tune established nutritional concepts.Figure 1: Average soy bean prices over the last five years (www.indexmundi.com)

Adapting dietary specifications for maximal net profit

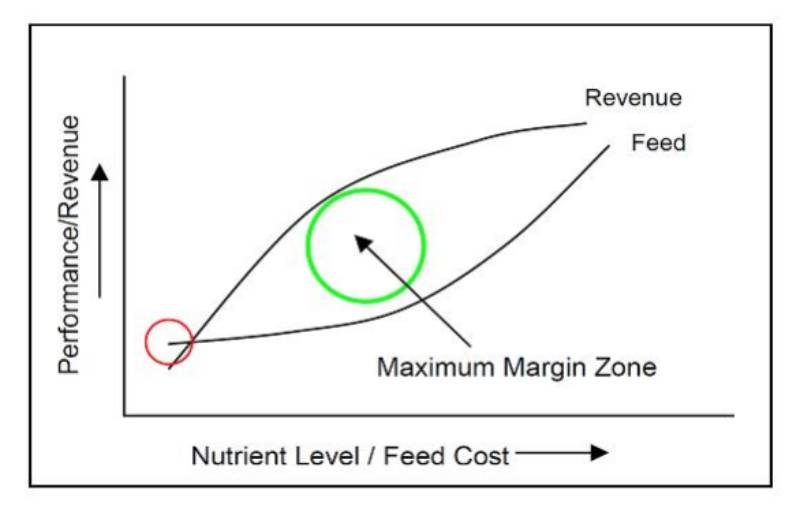

The first critical point to verify and reflect on is dietary specifications. What level of energy, protein and amino acids do we need in different diets? The specification must not solely aim to keep feed cost as low as possible, or to maximize animal performance. Rather, they must be defined to yield maximum profit from the whole system. Figure 2 shows the relation between dietary nutrient concentration and feed cost, performance and revenue. Both revenue and feed cost increase with higher nutrient density in the diet (Waller, 2007). The green zone marks the area with maximal difference between the revenue curve and feed cost curve. When setting the nutrient levels in this range, the margin for ‘revenue over feed cost’ is highest. As feeding cost is a major production issue, this is also likely to represent the area with maximal net profit. A consistent production system with accurate data on animal performance and carcass value are needed to fine-tune the system. This basic information is available in most broiler operations, as bird genetics and the overall production system are well standardized. Many swine fattening farms also have such data available to define the nutrient concentrations which are most suited for their genetics and the market conditions they operate under.Figure 2: Effect of feed dietary nutrient concentrations on feed cost, performance and revenue

(Waller, 2007)

Feeding as close as possible to set specifications or requirement

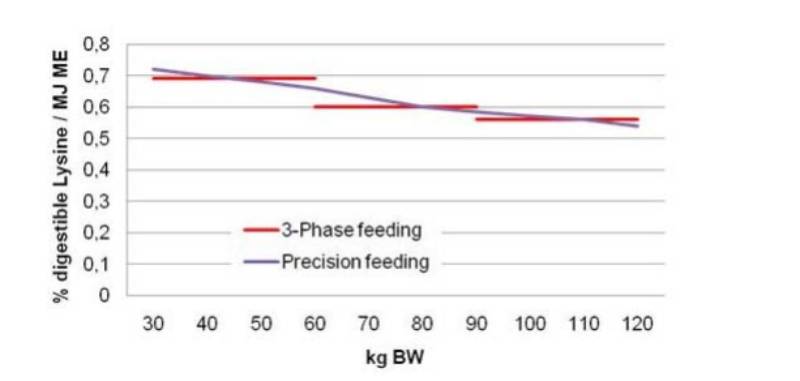

High ingredient prices will raise the cost of safety margins and formulation inaccuracies. The current cost for protein is forcing producers to minimize safety margins. In order to keep safety margins low and, at the same time, avoid the risk of under-formulation, accurate knowledge of the quality and nutrient content of raw materials is essential. Ingredients have to be analyzed in as detailed a manner as possible and stored, blended and included based on quality.As the requirement changes throughout the production cycle, feeding close to requirements and set specifications is more achievable with proper phase feeding. The current market situation might make it interesting to add an extra feed in the phase feeding program, i.e. to go from two to three or from three to four diets throughout the growth of the animals (Figure 3). However, the logistical cost for an additional feed and its storage has to be weighed carefully against any gains from feeding precision.

Depending on the feeding system it might be worth looking at precision feeding by changing the ratio of a starter diet (being adapted to the requirements for the first day of the grower phase) and the finisher diet (being adapted to the requirement for the day before slaughter). With this approach, amino acid supply will exactly follow the change in requirement with no over- or undersupply at any time during the growing cycle (Figure 3). Liquid feeding systems or spot mix systems lend themselves well to this approach.

Figure 3: dLys/MJ DE with a 3-phase feeding system and with precision feeding with two

diets with 0.72 and 0.54 g dLysMJ/ME where ratio is adapted each day to exactly

meet the requirement of fattening pigs

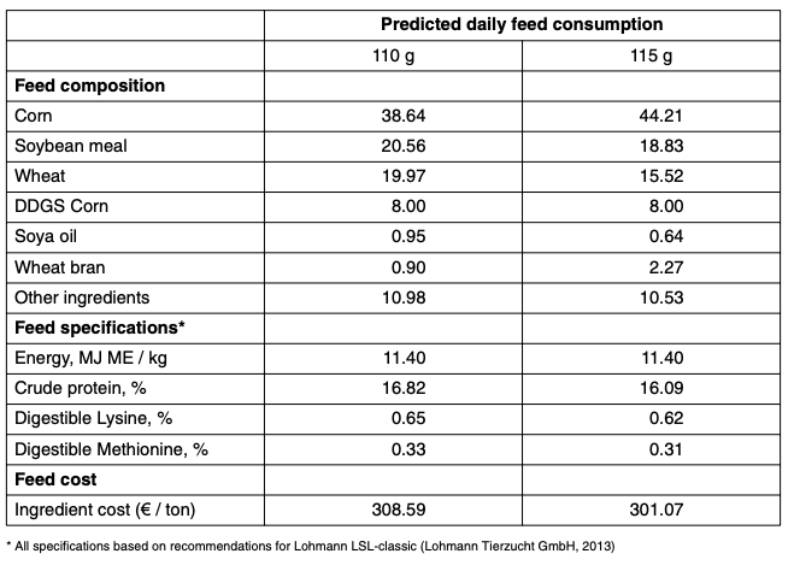

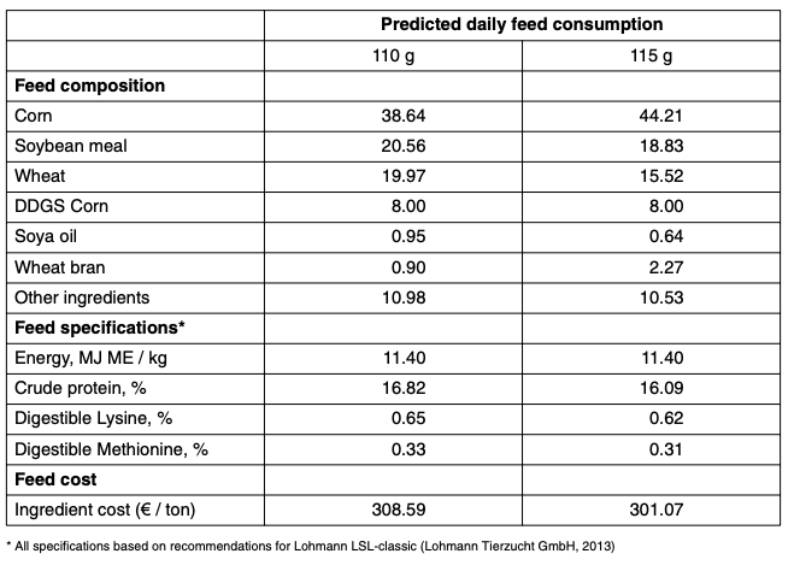

For laying hens, in order to closely meet protein and amino acid requirements it is essential to have precise data on feed intake. The protein requirement of a healthy laying hen primarily depends on her body weight and production needs. However, energy intake is considerably affected by environmental temperature and locomotion. As birds adjust intake to meet their energy requirements, the amount of protein they need must be adjusted accordingly. If we formulate a diet to meet the requirement at an intake of 110 g/d, and the flock actually consumes 115 g/d, they will over-consume protein by about 5%, which will be wasted and contributes to extra ammonia emissions from the excreta. Under current market conditions the diet at an intake of 110 g/d will cost € 308.59 per ton and the diet for 115 g € 301.07 per ton (Table 1). Feeding the formulation for an intake of 110 g when birds are eating 115 g will result in extra cost of € 7.52 per ton of feed or € 31’500 for a 100’000-layer operation over a year. Automated and accurate measurement of feed intake should therefore be standard in any commercial layer house. If we consider having two diets on farm, one formulated to meeting the requirements when feed intake is high and one when it is low, then mixing those two diets accordingly will hit the requirements exactly.

Use of alternative ingredients

High soy prices make alternative ingredients more attractive. However, their availability is limited. When partially replacing soy bean meal, DGGS and rape seed meal, both by-products of the biofuel industry are of particular interest. However, their protein digestibility is lower compared to soy and can be more variable. Therefore, all formulations with alternative ingredients must be based on digestible amino acids. Formulations based on digestible protein and amino acids should be applied as standard in all diet formulations anyway. If operations are still formulating based on total amino acids, the inclusion of alternative ingredients is a good reason to adapt the system and modernize the approach to formulation.Table 1: Effect of expected feed intake on feed specification, composition and cost in layers

DGGS in particular poses a relatively high risk for mycotoxin contamination, thus raw material quality

has to be controlled carefully. A comprehensive review on the use of DDGS in poultry has recently

been published in World’s Poultry Science Journal (Salim et al. 2010). The authors concluded that

high quality DDGS can be fed to broilers, laying hens and turkeys without adverse effect on growth and

performance. However, in order to maintain the consistency of DDGS quality from batch to batch,

they recommended obtaining DDGS from a specific processing plant. For swine, Stein and Shurson

(2009) have reviewed the literature and concluded that DDGS can be an excellent source of energy

and digestible P in diets fed to swine at all production phases. Nutrient concentration and digestibility

vary among sources, and accurate in vitro methods need to be developed to predict amino acid

digestibility. Acceptable growth performance can be achieved by adding up to 30% DDGS in diets

fed to grower-finisher pigs. Thus DDGS, when available at the right price and quality, can help to

maximize margins over feed cost.

DGGS in particular poses a relatively high risk for mycotoxin contamination, thus raw material quality

has to be controlled carefully. A comprehensive review on the use of DDGS in poultry has recently

been published in World’s Poultry Science Journal (Salim et al. 2010). The authors concluded that

high quality DDGS can be fed to broilers, laying hens and turkeys without adverse effect on growth and

performance. However, in order to maintain the consistency of DDGS quality from batch to batch,

they recommended obtaining DDGS from a specific processing plant. For swine, Stein and Shurson

(2009) have reviewed the literature and concluded that DDGS can be an excellent source of energy

and digestible P in diets fed to swine at all production phases. Nutrient concentration and digestibility

vary among sources, and accurate in vitro methods need to be developed to predict amino acid

digestibility. Acceptable growth performance can be achieved by adding up to 30% DDGS in diets

fed to grower-finisher pigs. Thus DDGS, when available at the right price and quality, can help to

maximize margins over feed cost.Since the levels of gucosinolates have been reduced in rape through genetic selection, rape seed meal or other by-products from the plant oil industry are potentially good protein sources for animals.

Maximum levels of inclusion for monogastrics vary depending on the source of information, however most are in the range of 5 to 15%, although in diets for young animals, only low levels should be incorporated. Several German research institutes have compared pig grower-finisher diets with and without rape seed meal/cake inclusion (Priepke et al., 2008, Frickh et al., 1998; Weiss, 2008). Meyer et al. (2006) compared iso-nutritional diets with no rape seed cake or with 10% inclusion in a standard diet for pigs. They found no adverse effects of the rape cake inclusion on key performance parameters (Table 2). By-products from the plant oil industry will affect carcass fat quality. It should be monitored closely when using such by-products.

Table 2: Effect of rape cake inclusion on performance of grower-finisher pigs

Several publications have reported cost savings by using rapeseed meal as a protein source. However, any such trial data have to be assessed taking into consideration current market prices.

Maximizing diet digestibility

Taking measures to maximize diet digestibility in general, and protein digestibility in particular is important for several reasons. Firstly, high digestibility means a high amount of absorbed nutrients and thus efficient use of the feed. Secondly, high digestibility will reduce nutrient excretion and thus lessen the environmental impact from the livestock production system. Thirdly, high ileal digestibility will reduce the flow of protein to the lower digestive tract. This decreased flow of undigested protein can improve the gut environment and impact on intestinal health and immune defenses. In poultry diets, high protein concentrations have been shown to favor the proliferation of potential pathogens such as Clostridium perfringens (Drew et al., 2004). High protein concentrations will also lead to increased uric acid in the excreta, which is known to be linked to higher litter moisture, and hence hock, feet and breast lesions. Thus protein digestion should be maximized and dietary protein concentration be kept low. In piglets, diets with decreased protein content have been shown to reduce the indices of protein fermentation and the incidence of post weaning diarrhea (Heo et al., 2009).Many different factors such as diet composition, quality of ingredients, diet processing and enzyme use affect diet digestibility. Grinding (particle size) and thermal treatment are the two key issues in the feed manufacturing process that impact diet digestibility. Pelleting and other thermal treatments can improve diet digestibility. In times of high feeding cost any increment in improved digestibility is worth more money and thus the economic impact of thermal treatment is larger in today’s market with high ingredient cost. Particle size and overall feed structure is another factor to review and optimize.

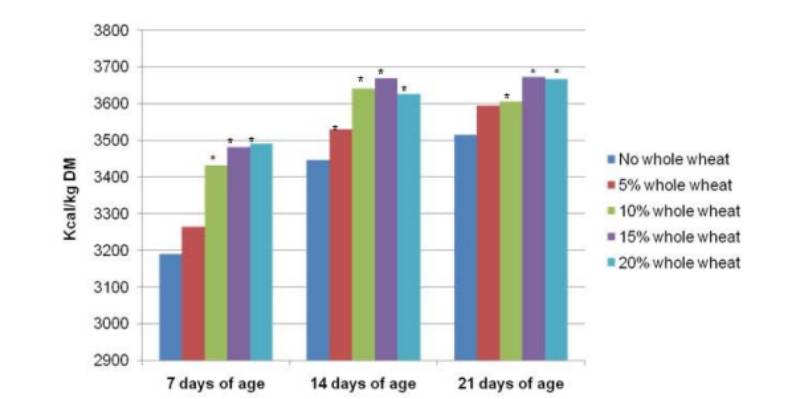

Research shows beneficial effects of whole wheat feeding on diet digestibility and production efficiency in broilers. The use of whole wheat has been shown to increase gizzard weight, and feeding 10% to 20% whole wheat can increase ME (figure 4) and amino acid digestibility (Biggs and Parsons, 2009).

Whole wheat feeding is quite common in northern Europe. However, in the other parts of the world this approach still offers significant potential. The concept is particularly interesting for poultry farms that also produce wheat or farms which can buy wheat directly off the field from neighbor farms.

Digestive enhancers such as enzymes must be applied to their full potential. The final utility per unit used will decrease with higher inclusion levels; however, at high ingredient cost, higher inclusion levels can be justified. When feeding precisely on the requirement, it is likely more economical to assign a nutrient value to the enzymes and to reformulate the diet than to add the enzyme on top of an already formulated diet. Of course the change in utility per unit used with higher inclusion levels has to be properly taken into account.

Figure 4: Effect of whole wheat feeding on energy utilization in broilers

(Biggs and Parsons, 2009)

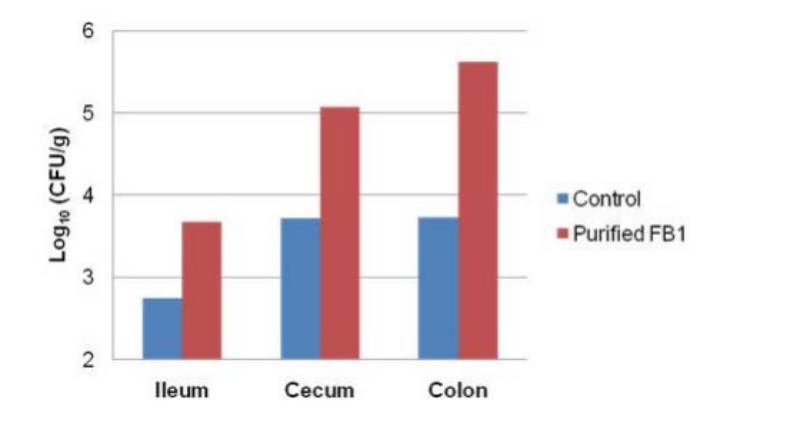

Control of mycotoxins

Recently, animal feed had to be withdrawn from hundreds of farms in Germany and the Netherlands following the discovery of aflatoxin, a carcinogenic, in dairy milk. The mycotoxin was introduced into the feed via corn from Eastern Europe. This case once again demonstrated that transparency in the market combined with analytical control is key to guarantee feed and food safety. While aflatoxin, due to its transfer in animal products and its carcinogenic properties in humans, is strictly regulated with maximum legal limits, for other toxins only vaguer values for limits exist. However, as such toxins affect animal performance and health, their control is critical to optimize feed utilization (Zaki et al., 2012). Fumonisin B1 (FB1) can cause increased translocation of bacterial pathogens across the intestine. In piglets, oral administrations of FB1 for seven days significantly increased colonization of the small and the large intestines by pathogenic E. coli strains (Oswald et al., 2003) and enhanced the bacterial translocation to extra-intestinal organs (Figure 5).Figure 5: Oral administration of FB1 significantly increases the gut colonization of E. coli

(Oswald, et al., 2003)

The control of mycotoxins starts with crop production. It is well established that crop rotation, cultivation practices (e.g. direct seeding enhances the risk for mycotoxin production) and the variety which is planted greatly affects the mycotoxin risk. In most situations, the feed producer does not produce their own crops, so good communication and market transparency is critical. To assess the mycotoxin risk, it is essential to know the source. Insufficient and excessive rainfall during critical phases of crop development can lead to mold contamination, spoilage of grain, and mycotoxin production.

Also post-harvest handling of grain presents opportunities for controlling mold growth and its consequences. Careful drying of grains and good storage management should minimize post-harvest fungal growth and, therefore, mycotoxin production. If several factors point towards an enhanced risk for mycotoxin presence, or contamination has been confirmed by analysis, the inclusion of an additive or feed ingredient which has been shown to reducing the negative impact of mycotoxin should be considered (Chowdhury and Smith, 2004; Zaki et al., 2012; Boudergue et al., 2009). Very significant advances have been made over the last couple of years in mycotoxin analyses. Novel mass spectrometry techniques are commercially available which allow simultaneous analyses for up to 40 mycotoxins (http://www.mycotoxinmanagement.com/MIKO). This gives a much more comprehensive picture of the challenge a herd or flock is exposed to. A proper analysis of the situation is the key to put together and implement the most efficient package of measures.

Maximizing overall animal performance and intestinal health

Poor animal health is the most important factor that affects the efficient use of feed in commercial production systems. A recent study by Riklin and Hartmann (in press) shows that many farms have considerable room to improve management practices in order to optimize animal health, performance and welfare. Sollberger et al. (2013) determined that, on Swiss pig farms, during the grower-finisher phase on average 33% of feed protein was retained in body tissue. However, the variation between farms in protein efficiency was very large despite the use of comparable genetics and even when using similar diets. This clearly shows a huge potential for improving efficiency by optimizing animal health. Poor animal heath will depress feed intake and thus reduce the nutrient which are available to the animal. Disease will also increase the nutrient requirements for maintenance. This will reduce the nutrients which are available for growth and thus affect production efficiency. Maximal overall animal and intestinal health can only be achieved when housing, biosecurity, health management, nutrition and host defense are at its best. Many factors which have already been discussed can positively impact intestinal heath. Dietary specifications, ingredient choice, measures to maximize diet digestibility or to control the negative impact of mycotoxins can all contribute to better intestinal health. In addition, specific feed ingredients or feed additives can give vital extra increments of improvements. Their efficacy can be challenged when exposing animals under controlled conditions to disease. A recent trial from the University of Wageningen shows that Actigen™, a yeast cell wall based feed product, can reduce the impact of E. coli in weaning piglets. Not only was the ingredient able to reduce the concentration of the pathogen, those animals with reduced pathogen load and stress in the digestive tract, showed that feed intake was much less affected. This will reduce the growth check which typically occurs during such disease events. In poultry, a recently published meta-analysis demonstrated that using Actigen™ significantly and beneficially changed body weight by +0.080 kg (+3.34%), FCR or F/G ratio by -0.033 (-1.84%) and mortality % by -0.80 compared to a negative control (Hooge et al., 2013).Enhanced buying power

There is no single measure that will bring the improvements in efficiency the producers need in the current market. The entire system must be thoroughly reviewed and existing margins for improvement exploited in all areas of production. The efficacy of the different measures will vary from case to case with animal production systems. The only measure that can bring fully predictable results is buying the same quality feed at a lower price. Depending on the market situation, farmers have to work with large companies as trading partners and hence often lack leverage when it comes to buying and negotiation power. Pooling demand and approaching the market from a stronger position must be considered as an approach to improve farm profitability and assure the capability to invest in production operations and thus give the business a long-term future.References

Biggs, P. and C.M. Parsons (2009) The effects of whole grains on nutrient digestibilities, growth performance, and cecal short-chain fatty acid concentrations in young chicks fed ground corn-soybean meal diets. Poultry Science 88:1893- 1905.Boudergue, C., C. Burel, S. Dragacci, M. Favrot, J. Fremy, C. Massimi, P. Prigent, P. Debongnie, L. Pussemier, H. Boudra, D. Morgavi, I. Oswald, A. Perez and G. Avantaggiato (2009) Review of mycotoxin-detoxifying agents used as feed additives: mode of action, efficacy and feed/food safety. SCIENTIFIC REPORT submitted to EFSA. http://www.efsa.europa.eu.

Chowdhury, S. R. and T. K. Smith (2004) Effects of Feeding Blends of Grains Naturally Contaminated with Fusarium Mycotoxins on Performance and Metabolism of Laying Hens. Poultry Science 83: 1849-1856.

Drew, M. D., N. A. Syed, B. G. Goldade, B. Laarveld, and A. G. Van Kessel (2004) Effects of dietary protein source and level on intestinal populations of Clostridium perfringens in broiler chickens. Poultry Science 83: 414–420.

Frickh, J. J., W. Wetscherek und W. A. Pichler (1998) Untersuchung über den Einsatz von Rapssaat und deren Auswirkungen auf die Mast- und Schlachtleistung sowie auf die Fleischqualität in der Schweinemast. Die Bodenkultur 49: 39-49.

Heo, J. M., J. C. Kim, C. F. Hansen, B. P. Mullan, D. J. Hampson, and J. R. Pluske (2009) Feeding a diet with decreased protein content reduces indices of protein fermentation and the incidence of postweaning diarrhea in weaned pigs challenged with an enterotoxigenic strain of Escherichia coli. Journal of Animal Science 87: 2833–2843.

Hooge, D.M., A. Kiers and A. Connolly (2013) Meta-Analysis summary of broiler chicken trials with dietary Actigen™ (2009- 2012). Int. Jour. of Poultry Sci. 12: 01-08.

Le Gall M., M. Warpechowski, Y. Jaguelin-Peyraud and J. Noblet (2009) Influence of dietary fibre level and pelleting on the digestibility of energy and nutrients in growing pigs and adult sows. Animal 3: 352-359.

Lohmann Tierzucht GmbH (2013) Layer management guide for LSL-Classic. www.ltz.ch.

Meyer, A., A. Schön, W. Brade und P. Köhler (2006) Einsatz von Rapskuchen in der Schweinemast. In: M. Rodehutscord (Hrsg.): 9. Tagung Schweine- und Geflügel-ernährung, 28.-30. November 2006, Universität Halle-Wittenberg, 147-149.

Oswald, I. P., C. Desautels, J. Laffitte, S. Fournout, S. Y. Peres, M. Odin, P. Le Bars, J. Le Bars and J. M. Fairbrother (2003) Mycotoxin Fumonisin B1 Increases Intestinal Colonization by Pathogenic Escherichia coli in Pigs. Applied and Environmental Microbiology 69: 5870-5874.

Priepke, A., C. Schubert, W. Hackl und R. Pfuhl (2008) Rapskuchen in der Schweinemast. Schweinezucht aktuell 33: 39- 41.

Salim H. M., Z. A. Kruk, and B. D. Lee (2010) Nutritive value of corn distillers dried grains with solubles as an ingredient of poultry diets: A review. World’s Poultry Science Journal, 66: 411-432.

Sollberger E., Bracher A., Burren C. und P. Spring (2013) N-Input, N-Anfall und N-Effizienz in Schweine(mast)betrieben als Indikatoren der Ammoniakemissionen. Agrarforschung Schweiz 4: 10–15.

Stein, H. H. and G. C. Shurson (2008) BOARD-INVITED REVIEW: The use and application of distillers dried grains with solubles in swine diets. Jour. of Animal Sci. 87: 1292-1303.

Waller, A. 2007. Economic approach to broiler production. Roos Tech Notes, Sept. 2007. www.aviagen.com.

Weiss, J. (2008) Entwicklung des Rapsschrot-/Rapskuchen-Absatzes. Oelsaatenhandelstag, 24./25. September 2008, Bundeslehranstalt Burg Warberg.

Zaki, M. M., S. A. El-Midany, H. M. Shaheen and L. Rizzi (2012) Mycotoxins in animals: Occurrence, effects, prevention and management. Journal of Toxicology and Environmental Health Sciences 4: 13-28.

Zusammenfassung

Die hohen Futtermittelpreise setzen Tierproduzenten und Futtermittelbranche unter enormen wirtschaftlichen Druck. Die gesamte Branche ist gefordert, zusätzliche Anstrengungen zur Futterkostenoptimierung zu unternehmen. Die Kostensenkung muss erzielt werden, ohne den Druck des Marktes nach weniger Antibiotikaeinsatz, höherer Produktequalität und –sicherheit und artgerechterer Haltung aus den Augen zu verlieren. Diese Herausforderungen zwingen alle Beteiligten in der Produktionskette die Ernährungs-:und Haltungspraktiken weiter zu verbessern. Der vorliegende Artikel fasst Ansätze zur Feinabstimmung der Fütterung zusammen. Zur Verbesserung der Marge in der Tierhaltung müssen Energie- und Nährstoffgehalte der Rationen kritisch hinterfragt und Phasenfütterungskonzepte weiter optimiert werden. Wenn alternative Futtermittel zum richtigen Preis erhältlich sind, bieten sie einen interessanten Ansatz die Futterkosten zu senken. Bei der Verwendung von alternativen Futtermitteln und gleichzeitigem Druck den Antibiotikaeinsatz zu reduzieren, muss der Darmgesundheit besondere Beachtung geschenkt werden. Eine hohe Proteinverdaulichkeit hilft das Auftreten von Verdauungsproblemen zu minimieren. Zusätzlich gilt es die Mykotoxinbelastung tiefzuhalten und die Darmgesundheit mit dem Einsatz spezifischer Futtermittel oder Futterzusätze weiter zu verbessern. Das gesamte System muss gründlich überprüft werden, um bestehende Spielräume zur Verbesserungen in allen Bereichen der Produktion nutzen zu können.

Assine nosso boletim informativo

And find out about all the latest industry news.