Introduction

Since the decision to ban conventional cages in the EU by 2012, individual countries have passed laws for the transition period. Many egg producers are still undecided whether to invest in new facilities compatible with legal limitations or to give up egg production. Until a few years ago, most egg producers and poultry scientists agreed that cages were acceptable as a compromise between the needs of laying hens and the interests of producers and consumers.Unresolved problems with non-cage management of laying hens have been pointed out repeatedly in the past (e.g. Flock, 1982; Flock et al., 2003), but we need to take a fresh look at this issue in view of the fact that conventional cages will be completely phased out in Germany a year from now. In the very near future, potential investors have to find answers to three questions:

(1) If they invest in enriched cages (or “Kleingruppenhaltung”, a German version with more wellness for the hens than the EU minimum requirements), can eggs from these facilities be marketed with a sufficient profit margin?

(2) If they invest in a non-cage system, will they be able to provide the advanced management required for predictable results and recover the higher cost with a premium price?

(3) To what extent are differences between strains apparent and relevant for theses decisions, and are results from small groups in Random Sample Tests repeatable in large groups on production farms?

General review of alternative management systems

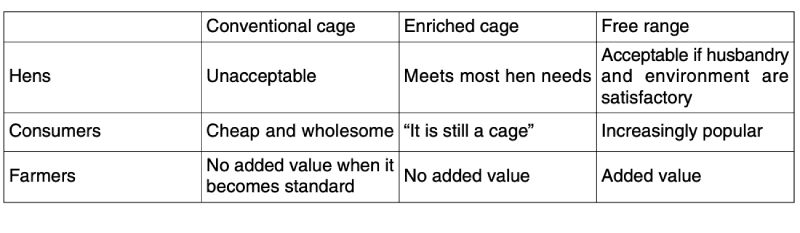

In his plenary lecture at the World Poultry Congress in Brisbane, Webster (2008) reviewed the development of theoretical and applied animal welfare in a historical context and from different points of view. As shown in table 1, hens and consumers may differ in their perception of different production systems:In his plenary lecture at the World Poultry Congress in Brisbane, Webster (2008) reviewed the development of theoretical and applied animal welfare in a historical context and from different points of view. As shown in table 1, hens and consumers may differ in their perception of different production systems:

Table 1: The welfare of laying hens in different production systems as perceived by the hen

and by the people (Source: Webster, 2008)

According to Webster, essential needs of the hens are met in “enriched” cages: much more space and opportunity to move around, dark nests, a dust bath and perches at different levels. With the term “Kleingruppenhaltung”, German producers of eggs and equipment for the egg industry have tried to avoid the term “cage” and focus on the advantages of small groups in terms of behaviour and reduced risk of cannibalism and feather pecking. Not unexpectedly, opponents of non-cage systems

launched a campaign against this system and it is not clear whether the egg industry will succeed in its attempts to get away from the current labelling (3 = cage production) which does not distinguish between conventional cages and enriched cages. At least two major discounters have decided that they will not list eggs from any cage system – ignoring the fact that many consumers prefer to make their own decisions on the basis of “value for money”. The outcome of this dispute is still open, and egg producers must try to stay in business by keeping up with all relevant information.

Comparisons of Cage vs. Floor in German Random Sample Tests

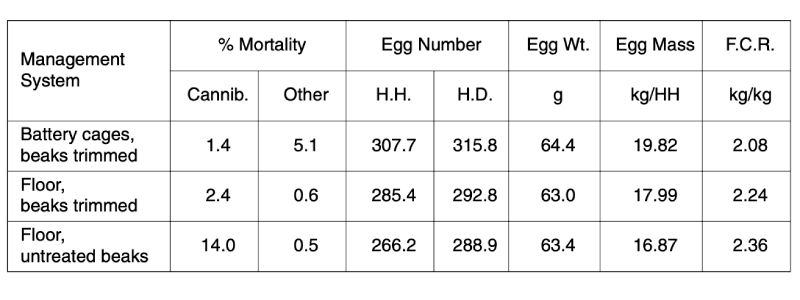

In view of the expected ban of conventional cages in the EU, three out of five random sample testing (RST) stations in Germany discontinued their activities several years ago. Only two stations remain: Kitzingen in Bavaria changed to floor management in 1998, Haus Düsse recently installed “Kleingruppenhaltung”, a form of enriched cages with more space than EU specifications.Data comparing RST cage results from Haus Düsse with floor results in Kitzingen were presented 5 years ago at the Baltic Poultry Conference in Sigulda (Flock, 2003). Highly significant differences in mortality, hen-housed egg mass, feed conversion ratio and egg income minus feed cost were documented, with repeatable strain differences in three years. In the meantime, more data from 5 tests each (ending in 1999 – 2004) were analyzed and are presented in Table 2.

Table 2: Least squares means for major traits from cages (Haus Düsse) vs. floor (Kitzingen,

with and without beak treatment); 5 tests each (1999-2004)

Two results are immediately obvious: higher mortality due to cannibalism if pullets are not beak treated, and negligible mortality due to “other” causes under floor conditions. It is not known to what extent the lower egg production under floor conditions is due to uncollected eggs (e.g. dropped through the slats or eaten by the hens?). Similar differences were observed for some strains almost 40 years ago in German RSTs during the change from floor to cage testing, when strains were tested in both management systems.

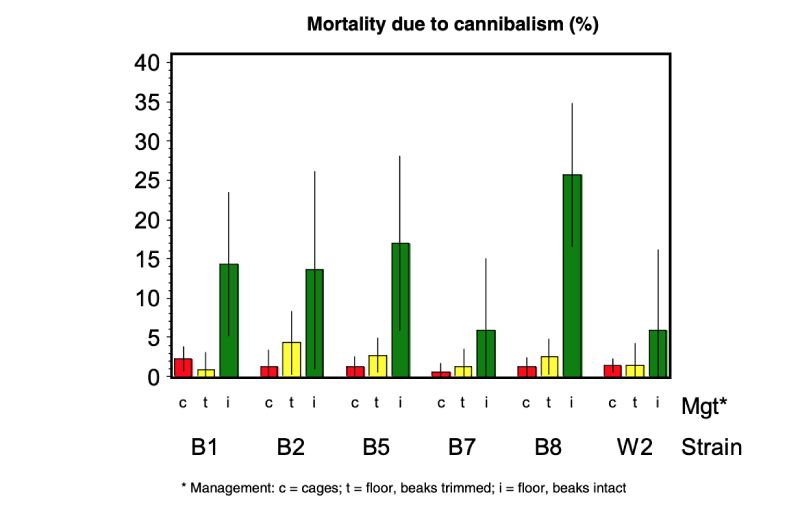

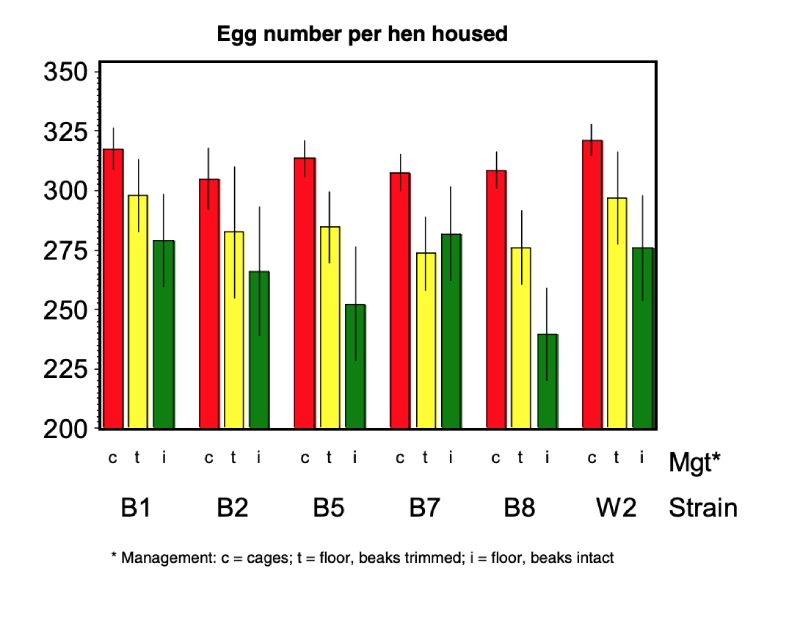

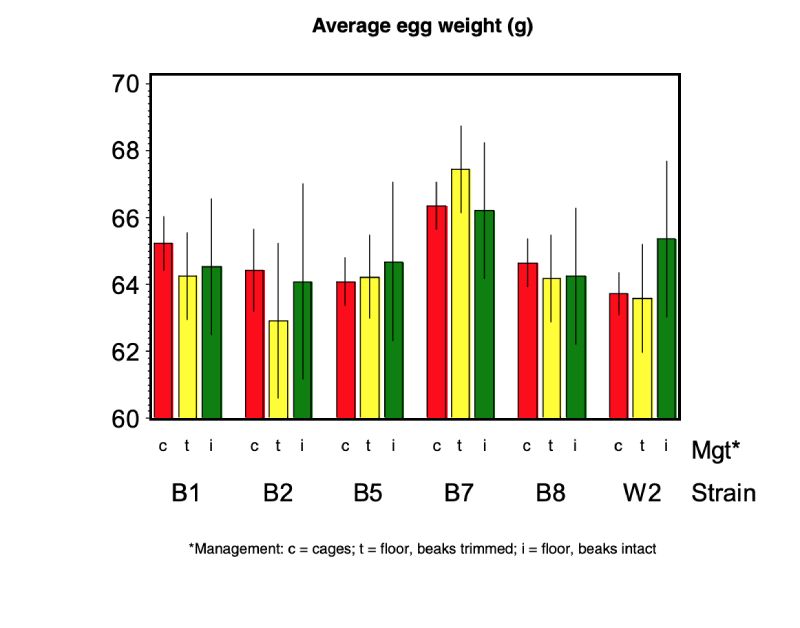

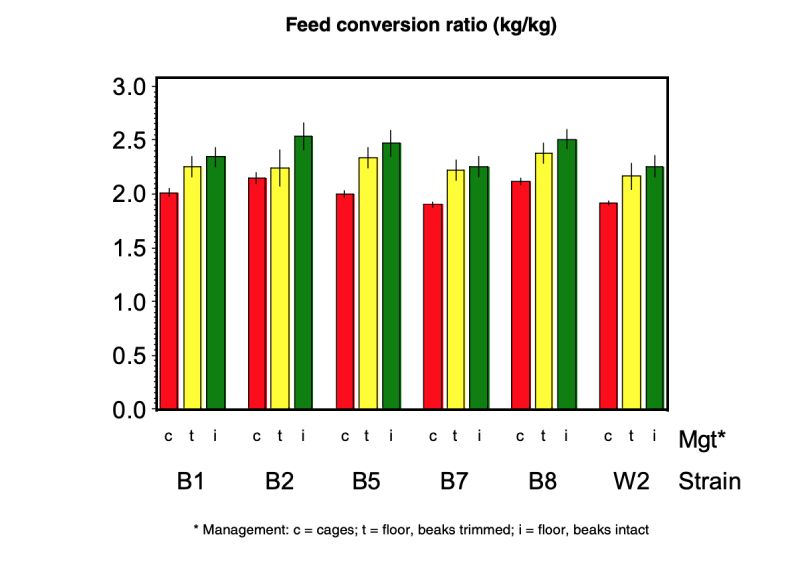

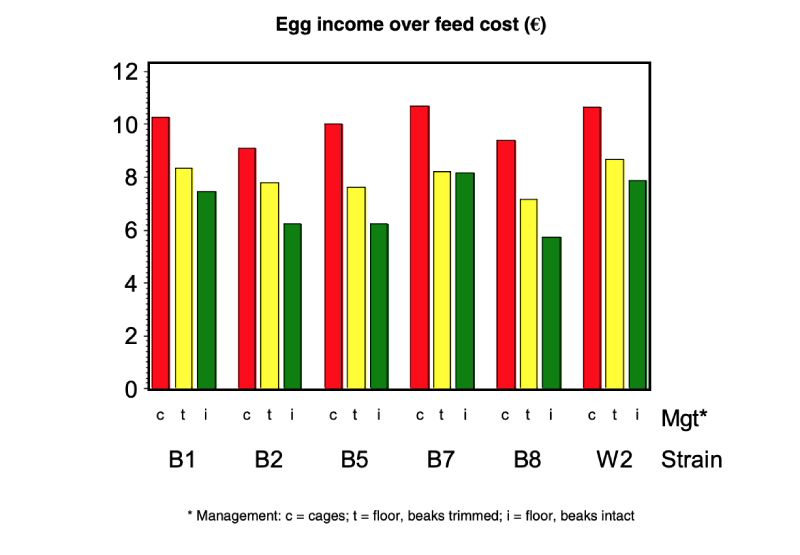

The variability of results within and between strains is illustrated in Figures 1-5 for five traits of major interest: (1) mortality due to cannibalism, (2) egg number per hen housed, (3) average egg weight, (4) feed conversion ratio and (5) egg income over feed cost.

As can be seen from the graphs, there are substantial differences among brown-egg strains in their susceptibility to cannibalism and correlated production traits. Only one out of five strains (B7 = Lohmann Tradition) has similarly low mortality as the only white-egg strain (W2 = LSL) represented with sufficient frequency in these tests to be included in the statistical analysis.

Figure 1: Strain x Management Interactions in German RST

Figure 2: Strain x Management Interactions in German RST

Figure 3: Strain x Management Interactions in German RST

Figure 4: Strain x Management Interactions in German RST

Figure 5: Strain x Management Interactions in German RST

Data from commercial egg production farms in Germany

A detailed analysis of field records from egg production farms in Germany was published by Bergfeld et al. (2004), based on a sample of 34 flocks from 17 farms, exclusively with floor management, varying between 500 and 20.000 in size. The results were evaluated in terms of economics, nutrition, product quality, poultry health and environmental impact (emissions and condition of free range after repeated use). The main conclusions were:a) variation between flocks in all criteria studied indicates a high risk for producers

b) free range management is the most risky form of management

c) beak treatment is still necessary to limit risks of cannibalism and feather pecking

d) hygienic egg quality is effectively improved by slats, separating hens from litter

e) rearing conditions must correspond to the equipment in the laying unit; information on feeding, vaccination, lighting etc. must be made available at housing of pullets. Strain differences are not documented in detail, but two findings are of special interest in the context of the present paper:

> white-egg layers averaged 89.4% rate of lay vs. 77.0% for brown-egg layers

> mortality averaged 11.8%, but ranged between 3.3 and 36.8%!

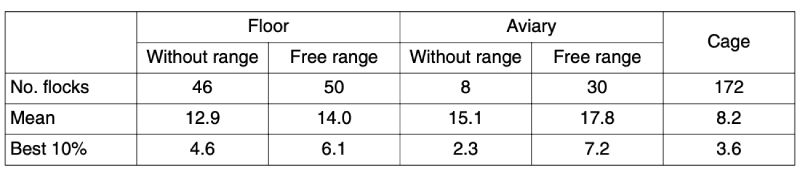

In Table 3 results of a study by Kreienbrock et al. (2004) are summarized based on 172 flocks in cages and 134 in floor systems. Average mortality in different floor systems ranged from 12.9 % to17.8 % — compared to 8.2 % in conventional cages — and slightly higher with free range than without access to free range.

Table 3: Laying mortality in different housing systems (Source: Kreienbrock et al., 2004)

Although egg production is obviously less risky in cages and therefore more attractive for producers, consumers will eventually decide how eggs are produced. Therefore we must focus on the variation of results within systems, analyze repeatable causes of variation and learn from the best flocks.

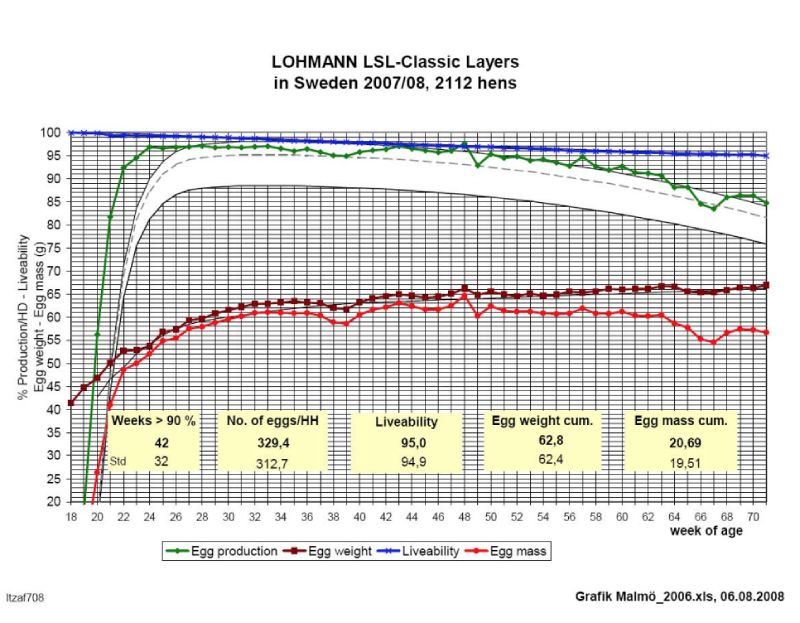

A case study in Sweden: organic egg production with LSL hens

My career as geneticist started with the HNL breeding program 40 years ago, when we were still keeping our elite stocks exclusively on the floor and tested pedigreed crosses under floor and single cage conditions. Therefore I was curious to find out whether the current generation of LSL White Leghorns still copes well with floor management. I am happy to share with you results recently obtained from Lars Norrman in Sweden, who started to produce organic eggs a few years ago, after working 40 years in production and customer service for a company.The results shown in Figure 6 are from an LSL flock on his farm in Southern Sweden, which recently completed a laying period to 71 weeks of age.

The excellent results shown in figure 6 were achieved by not only following strictly the general management recommendations for non-cage environments, but learning from own observations how to optimize the environment “from the birds’ point of view”. It is unlikely that similar results can be achieved if husbandry practices are decided in an office and carried out by farm personnel with limited knowledge and incentive to understand the needs of chickens.

The following recommendations may be used as a checklist to compare practices on other farms with the experience gained by Lars Norrman on his farm in successive flocks.

1. The management of the laying flock must start from the day of hatch.

Get all relevant information from the rearing farm: vaccination schedule, feed source and quality, body weight; uniformity should be at least 80%.

2. The rearing farm must have similar equipment as the laying unit.

Perches should be available from the beginning and will be used from one week of age. For organic egg production, a strict protocol must be followed.

3. Transfer the pullets to the laying house early enough.

Most egg producers plan to house the flock at about 18 weeks when the vaccination program is finished. Close to the onset of lay, the pullets are curious to discover the new environment and to find the nests. Norrman got the best results from hens housed already at 14 weeks, two weeks before the critical time (16 to 18 weeks) when major hormonal changes take place.

4. Proper light source and lighting program for open housing.

Windows are required for organic egg production, i.e. the lighting must take natural daylight into consideration. Lights must be gradually turned on and off. Conventional light bulbs are preferred over “energy-saving” tubes, which have been associated with nervousness. Consult experts for best light systems. Hens can be trained to return from free range with the sound of shutters before the end of the light day.

5. Consistent feed quality is the most critical factor.

A good working relationship with the feed supplier is essential. Keep samples from each batch of feed to be analyzed by an independent laboratory in case of suspected deficiencies. An unbalanced amino acid profile is a common risk factor of organic feed.

The feed structure in the rearing and laying farm should be similar. Prevention of selective feeding is especially important in floor housing systems. Sufficient crude fibre contributes to healthy guts and dry manure and may also reduce the risk of feather pecking and cannibalism (Pottgüter, 2008).

6. Litter quality and air quality have to be optimized.

With cage management in closed houses, it is relatively easy to maintain good air quality, and there is no litter problem. In floor houses, wood shavings are preferred over straw and easier to keep in good condition. Solar energy can be used and is sufficient most of the time, wood pellets may supplement heating on cold days.

7. Observe your birds daily, use veterinary help to diagnose problems.

Use your eyes, nose and ears to convince yourself that the hens are healthy and happy! Monitor water and feed intake daily. The first signal of feed quality problems or infections may be reduced water intake. By the time rate of lay and/or egg weight drops, it may be too late to correct the situation. Call for help of an experienced veterinarian to diagnose the situation if necessary.

8. Keep accurate records and focus on utilization of the genetic potential!

Try to combine the highest genetic potential with the best possible husbandry under your specific conditions. Without knowing what a given strain of layers can achieve in terms of liveability, egg production and feed efficiency and corresponding “goals”, it is impossible to assess the potential for further improvements. Avoid repeating the same mistakes and focus on what you can improve yourself instead of expecting solutions from others.

Discussion and conclusion

The management of random sample tests has to follow a given protocol to assure unbiased results and will be unable or reluctant to interfere if cannibalism starts in one group. Due to the small number of replicates, large differences between strains in traits like mortality are often not “statistically significant” and may be misleading. Primary breeders have additional information from many flocks around the world, enabling them to assess the relative risk of cannibalism in different strain crosses more reliably. Market shares of specific products reflect a combination of genetic potential, back-up with management recommendations and actual management on each farm. Primary breeders have been selecting against cannibalism for many years (Preisinger, 2001), and egg producers should monitor progress actually achieved with different strains while focusing on optimal management in their farm.Assuming that the results from different management systems in RSTs shown in table 2 reflect field conditions, we can make the following rough calculation: 464 Mio people in the EU-25 consume on average 13.3 kg egg mass, i.e. 6.17 Mio tonnes of egg mass. If all these eggs were produced in cages under conditions like in Haus Düsse, 311 million hens would have to be housed, 20 million of which would die. To produce the same egg mass under floor conditions without beak trimming, 365 million hens would have be housed, 53 million of which would die (mainly due to cannibalism). An additional 54 million pullets would need to be reared and 1.7 million tonnes of feed would be required to cover the less efficient feed conversion. In view of the growing competition between food, feed and fuel, this point should not be ignored in a balanced assessment of different options.

Differences between strains in their adaptability to specific management systems are relevant for the choice of the most promising strain for a given management situation. To maximize family income, the goal should be to combine the best strain with best management. The market will eventually decide from which hens in which system eggs are produced. Farm management should make use of information on strain differences to minimize hen mortality and thereby improve hen welfare.

In Germany, many consumers do not discriminate on shell colour or even prefer white-shelled eggs if they are offered in supermarkets. But non-cage eggs are usually associated with brown shells, and it would take a dedicated promotion to convince consumers that non-cage eggs can also be produced from White Leghorns, probably even more environment-friendly, because fewer hens and resources would be needed to meet consumer demands for eggs and egg products.

Bergfeld, U., K. Damme, M. Golze und W. Reichardt (2004): Evaluierung alternativer

Haltungsverfahren für Legehennen. Schriftenreihe der Sächsischen Landesanstalt für Landwirtschaft. Heft 8. (209 pp).

Flock, D.K. (1982): Im Zweifel für die Käfighaltung! DGS 34, 266-267

Flock, D.K., G. Heil and K. Damme (2003): Whither random sample testing for laying hens in Europe? Proc. 11th Baltic Poultry Conference, Sigulda, Latvia.

Flock, D.K. and L. Norrman (2008): Criteria for the competitiveness of different management systems and strain differences in the adaptability of laying hens to non-cage environments. Proc. 16th Baltic and Finnish Poultry Conference, Vantaa, Finland.

Kreienbrock, L., J. Schäl, M. Beyerbach, K. Rohn, S. Glaser und B. Schneider

(2004): EpiLeg – Orientierende epidemiologische Untersuchungen zum Leistungsniveau und Gesundheitsstatus in Legehennenhaltungen verschiedener Haltungssysteme. TiHo, Hannover.

Pottgüter, R. (2008): Fiber in layer diets. Lohmann Information 43 (2).

Preisinger, R. (2001): Recommendations for the future from a breeder’s perspectve. In: Blokhuis, H.J. et al., 2001: Feather pecking: solutions through understanding.

Proc. of seminars held in Skövde, S; Lelystad, NL; Edinburgh, UK.

Webster, A.J.F. (2008): Animal welfare and the environment. Proc. XXIII World Poultry Congress, Brisbane, Australia.

Zusammenfassung

Zur Anpassungsfähigkeit verschiedener Legehennenherkünfte an alternative HaltungdssystemeBis 2012 wird in der EU die konventionelle Käfighaltung von Legehennen beendet, in Deutschland muss die Umstellung auf alternative Haltungssysteme bereits bis Ende 2008 bzw. mit Übergangsregeln im Laufe des Jahres 2009 erfolgen. Es kommt jetzt darauf an, das Marktpotenzial für Eier aus der Kleingruppenhaltung auszuloten und die Umstellung auf Boden- bzw. Freilandhaltung durch positive Beispiele und entsprechende Managementempfehlungen zu unterstützen.

Ergebnisse aus deutschen Legeleistungsprüfungen zeigen ebenso wie Praxisdaten deutliche Vorteile der Käfighaltung, die sich auf die Kleingruppenhaltung übertragen lassen. Ob sich der Umstieg auf alternative Haltungssysteme rechnet, hängt für den einzelnen Betrieb von seinen Produktionskosten und dem zu erzielenden Preis ab. In jedem Fall sinnvoll ist eine gründliche Analyse der Varianzursachen mit dem Ziel, von den Betrieben mit den besten Ergebnissen zu lernen und eigene Fehler nicht zu wiederholen. Die Ergebnisse einer LSL-Herde in Schweden zeigen, dass die Produktion von BioEiern bei entsprechendem Management auch mit Weißen Leghorn möglich ist, sofern die Kunden nicht auf braunschalige Bio-Eier fixiert sind. Dabei sollte nicht vergessen werden, dass bei der Produktion von Bio-Eiern wegen der extrem hohen Futterkosten jedes zusätzlich verkaufte Ei relativ mehr bringt als bei den geringen Margen konventioneller Käfighaltung.