Introduction

In 2003/4 a project was initiated and financed by the Dutch agricultural ministry to develop new housing systems for laying hens that would be sustainable and acceptable by the public. The leading issue in the process of developing new housing designs was animal welfare and not directly cost reduction. The project resulted in two completely new designs (Bos et al. 2004, Bos & Groot Koerkamp, 2008). One of these, the Rondeel™, has been realized on commercial scale in 2010. Although theoretically the system was sound, it had not been tested and thus no experience with keeping hens in this system was available. Therefore research was conducted on the first flock to investigate the functioning of the system, the adaptation of hens to it, the use of the various areas and the fitness of the birds (Niekerk & Reuvekamp, 2011).The Rondeel™ is more expensive to build than traditional aviary or free range houses and therefore egg production costs are higher. This should be recouped by selling the eggs as a special product. This has been achieved in two ways. Firstly the eggs were sold in special boxes that uniquely identified the eggs as being produced in the Rondeel™. Secondly the eggs were sold with 3 stars of the special “Beter Leven” (better life) hallmark of the Dutch animal welfare organization “Dierenbescherming”. This Hallmark for animal welfare grants one, two or three stars to products in various supermarkets indicating the level of welfare the animals had during their life. Three stars is usually granted to organic farming, as in that type of husbandry no mutilations of animals are carried out (Dierenbescherming, 2011). The Rondeel™ was also granted three stars under the condition that hens would not be beak trimmed. An exemption was made for the first flock, because otherwise the risk for the farmer would have been too high (both a new, not tested husbandry system and not-trimmed hens). Therefore only a minority of the hens were not trimmed.

Layout

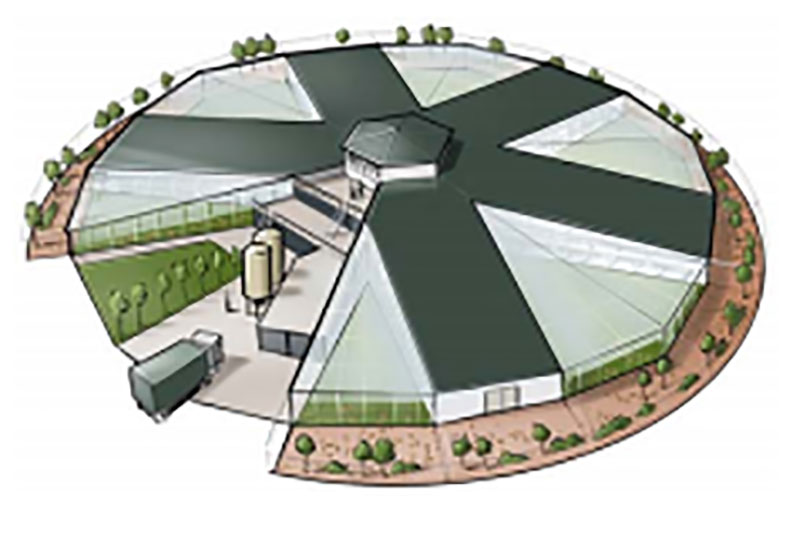

The Rondeel™ is a circular building that can house 30,000 hens in 6 sections, located around the central management quarters (Figure 1). Egg collection is located in these management quarters; also a manure drying tunnel is situated below ground level there. Visitors facilities are sited on the second floor and in the top of the building climate control with heat exchangers is located. To give access to the management quarters, the circle of the building is not completely closed. The 6 sections for the laying hens are not equal in size. The sections on either side of the entrance to the building are smaller and contain 3,000 hens each. The other 4 sections each contain 6,000 hens.

The large sections have night quarters (dark sections in drawing) on each side, a day quarter (bright sections in drawing) in the middle and a wooded fringe at the outer side. The two small sections only have one night quarter each. Night quarters are equipped with an aviary system (Bolegg Terrace from Vencomatic). Each night quarter is split in two halves by netting, making one part available for one section and the other part for the adjacent section. Day quarters have no separation and hens from both night quarters can use it freely.

The day quarters are located between the night quarters. Floors are covered with artificial grass. On the outer side a semi-circular box, filled with peat, provides dust bathing facilities. In the middle of the day quarters some circular drinkers are located. The roof of the day quarters is made of windand waterproof transparent material that makes the day quarters very bright. According to the manufacturer the transparent roof material lets through about 80% of the UV-light spectrum.

The wooded fringe comprises a circular area around the building, divided with wire fencing into 6 sections corresponding to the 6 inside sections. The earth floor is covered with woodchips. Originally it was furnished with trees and bushes, but these were destroyed by the hens in a few weeks. Later some tree stumps were placed in the wooded fringe. The outer circle of the wooded fringe forms a wire mesh fence. The top of the wooded fringe is covered with netting to prevent predators getting in and hens getting out.

Between the night quarters and the day quarters an insulated curtain over the full length can be rolled down to close off the night quarters. A netted curtain over almost the full width of the day quarters can be rolled down between the day quarters and the wooded fringe.

Economics

Eggs produced in the Rondeel™ are sold as barn eggs, as the wooded fringe does not meet the required dimensions for free range. To compensate for the more expensive Rondeel™ house a premium on the eggs is needed. This was realized by selling the eggs as a special product in specially designed round boxes made of coconut vessels. To argue why these eggs are special, some extra hallmarks are obtained. First the already mentioned animal welfare hallmark was obtained under the condition that no beak trimming would be performed. Indeed the second flock in the Rondeel™ is not trimmed at all. Another hallmark for environmental care (Milieukeur) was granted because the low energy cost of the system. Two heat exchangers from Agro Supply take care of climate control in the system and pre-and re-drying of the manure.An important characteristic of the Rondeel™ is the communication to the public. The house has a visitors aisle from where visitors can see the birds and the egg packing section. Visitors are also allowed to walk outside the wooded fringe and look at the birds from there. An active promotion is carried out to attract visitors and to make them understand how eggs are produced in a sustainable way.

Results rearing for first flock

The first flock in the Rondeel™ was of the Lohmann Brown Lite genotype, hatched on December 14, 2009. The pullets were reared in a house with in height adjustable platforms and ample daylight. The latter was deliberately chosen as the Rondeel™ house has a high level of daylight. In this way the difference between rearing and laying houses would be minimized. In the rearing house pullets had no access to free range. Grain was scattered to prevent feather pecking. At the end of the rearing period the feather cover of the hens showed signs of pecking damage (although this was not much considering the fairly high light intensity the birds received). Measures to prevent feather pecking were taken in the layer house as soon as the birds were housed, to reduce the risk of feather pecking continuing there. As for growth, feed intake and uniformity the rearing flock was average: not too heavy and not too light in bodyweight.Variation in the laying house

In the laying house the hens were housed in the 6 sections at 19 weeks of age. As mentioned, two sections housed 3000 hens and the other 4 sections housed 6000 hens. These 4 larger sections differed from each other in some details. One section had, as a test, a different artificial grass mat on one half of the day quarters. The other half of the day quarters had the same artificial grass as all other sections. One section had a visitor’s aisle running through the day quarters. This will be built in all Rondeel houses as it is part of the concept to open the house to visitors without compromising the hygiene. One section was populated with non-beak trimmed birds. The fourth large section had no specific features. In total 30,000 hens were placed.Light intensity

The sections were reasonably comparable in light intensity and variation was mainly caused by changing weather conditions. Night quarters were always darker than day quarters. The general light intensity in the Rondeel™ was much higher than that usually seen in layer houses: for the night quarters about 190 lux was measured and for the day quarters more than 3000 lux. The light intensity in the wooded fringe was almost equal to outside at about 6000 lux.The light distribution in the day quarters was very even. This was achieved by the roof design of the day quarters. The transparent material used filtered out sharp contrasts between shady and sunny spots.

Litter quality

The artificial grass mat slowly became soiled with manure. This was foreseen and the idea is to clean the mat during the laying period mechanically. However, no substantial cleaning of the artificial grass was carried out. There were two reasons for this. First of all the machine to clean the mat had to be newly developed and this was not yet ready at the time the first flock was in the Rondeel™. The second reason was, that by not cleaning a good impression could be obtained what would happen with the artificial grass over the time of the laying period. Thus, only some minor incidental cleaning was carried out, e.g. after a water leakage.Soiling of the artificial grass started at the sides along the night quarters and in the corners near the central unit. Although soiling at 42 weeks of age (the last measurement) was substantial, hardly any capped areas were seen. At the end of the laying period the artificial grass was completely covered with litter.

The litter in the night quarters stayed dry and loose. The litter in the dust baths (peat) initially was hardly used. It was not clear why this theoretically ideal dust bath material was not used, but a possible explanation could be that hens had ample possibilities to dust bath in the wooded fringe and in the night quarters. In the second part of the laying period litter material from the day quarters was moved to the dust baths and thereafter they were used more. The non-beak trimmed hens were also provided with bales of straw in the dust baths, making this area even more attractive.

Management

As the Rondeel™ had never been tested before, many management issues were unknown. When the first flock was housed, they were kept in the night quarters for a few days to facilitate them finding food, water and nest boxes. After a few days over the full length of the night quarters the curtains were rolled up, giving hens access to the day quarters. At first this was done in two steps. The curtains first were rolled up about 1 metre and a few hours later they were completely rolled up. This was done to make sure not too much light would fall on the nest boxes. Later experiences indicated that the curtains could be rolled up completely from the start without causing problems with floor eggs. When returning from the day quarters, birds can choose to enter the night quarter on the left or on the right. One of the first concerns was how the birds would distribute over these two night quarters. As the Rondeel™ is round, some night quarters are catching the last sun of the day, others are not catching any sun etc. If all birds would choose the same night quarter, problems with space and ventilation could be expected. However, there did not seem to be any tendency to use one night quarter more than the other. Up to the end of the first laying period birds distributed fairly evenly over both night quarters.Another concern related to the ventilation in the day quarters. These were naturally ventilated by means of the open side to the wooded fringe. No ventilation openings were made in the transparent roof. Theoretically this would be sufficient in hot circumstances, but some experts questioned if there wouldn’t be too much heat building up underneath the transparent roof. Fortunately during a hot period it appeared that the temperature at bird level was not too high and thus extra ventilation in the roof was not necessary.

At the end of the first flock the farmer indicated that the production was nodifferent from flocks in other non-cage systems. Mortality at 50 weeks of age was about 4.5%, which is normal for Dutch non-cage flocks.

Behavioural studies

To determine the use of the facilities in the Rondeel™ behavioural observations were carried out. After some pilot observations it became clear that live observations were not possible, because the birds were extremely calm and curious and reacted too much to the observers. Therefore video cameras were used to record behaviour in the night quarters, day quarters and wooded fringe. The number of observed areas differed for these 3 parts of the henhouse, as the size of these areas differed. For the behaviours given in table 1 the numbers of hens performing them were counted (scan sampling). After 10 minutes the counts were repeated. Before and after these counts the number of hens in the observed area were counted. For pecking behaviour (table 2) the same areas were used. During 5- 8 minutes (depending on the number of areas to observe) all observed pecks were recorded (continuous recording).Data were analysed using analysis of variance (continuous data) or a logistic regression analysis (percentages; GenStat Release 13.1). In case of significant differences (P<0.05) or a tendency to a difference (P<0.10) the procedures PAIRTEST (Performs t-tests for pairwise differences) and PPAIR (Displays results of t-tests for pairwise differences) were used.

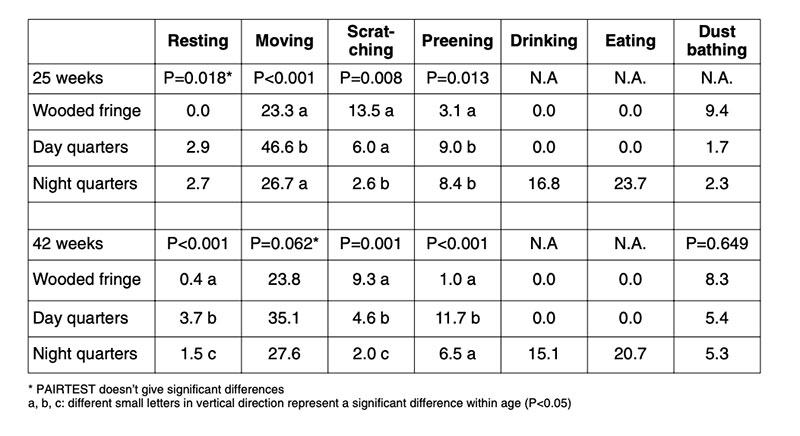

The results of the behavioural studies are given in tables 1 and 2. At 25 weeks of age more movements were seen in the day quarters compared to the night quarters and the wooded fringe. The spacious and light environment does in fact stimulate this. At 42 weeks of age however no significant difference was found for movements. In the night quarters less scratching and floor pecking were recorded, both at 25 and 42 weeks of age. In the wooded fringe less preening was seen at 25 weeks of age. At 42 weeks of age still less preening was seen in the wooded fringe, but also in the night quarters. Preening was mainly done in the day quarters. These findings are in accordance with expectations and do fit in the functions of the different areas.

Table 1: Behaviour at 25 and 42 weeks of age in the various areas of the Rondeel™

(% of number of observed birds)

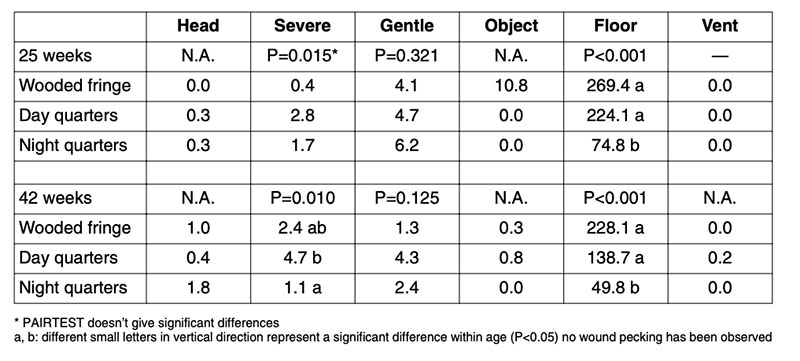

Table 2: Pecking behaviour at 25 and 42 weeks of age in the various areas of the Rondeel™

(% of number of observed birds)

For a number of behaviours differences were found between sections. Less movements were seen in the small sections and the section with a visitor’s aisle. This accords with the expectation, because in both situations there is less space for the hens to move over large distances.

With regard to feather pecking no problems have occurred. At 25 weeks there seemed to be a tendency to more severe feather pecking in the day quarters, but this difference was not statistically significant. At 42 weeks of age more severe feather pecking was recorded in the day quarters than in the night quarters. This could be expected based on the high light intensity in that area.

In the night quarters hardly any floor pecking was seen, despite the presence of litter. Probably the hens could satisfy their pecking behaviour enough on the artificial grass and in the wooded fringe.

Measurements exterior

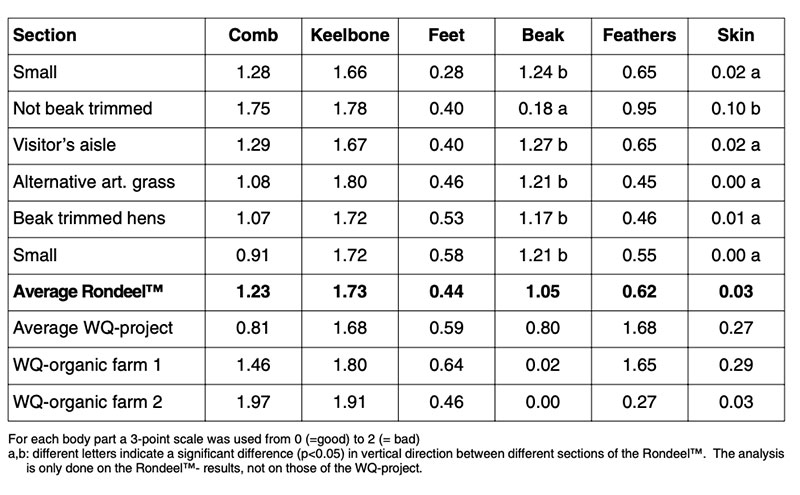

In table 3 the results of the measurements on exterior are given per section of the Rondeel™ and on average for the Rondeel™. The method according to Welfare Quality® was used (WQ 2009). From each section 100 birds were individually scored on six parts: comb (pecking wounds at comb), keel bone (strait or deformation), feet (condition foot pad), beak (beak shape), plumage (condition of the feathers on the back of the head and neck, on the back or around the vent area). These six items reflect possible welfare or pecking issues. For each body part the score runs from 0 (=good) to 2 (=bad). The average scores are given for all 6 sections of the Rondeel™ as well as the average over all six sections. The section with non-beak trimmed birds had better beak scores, which was according to expectation. Non trimmed beaks usually have no abnormalities and a normal shape of the beak, resulting in the best score (being 0). The average for this section was slightly higher than zero, because in the random sample of 100 birds for this section a few beak trimmed hens appeared present. As sections are only separated by a net curtain these trimmed hens will have originated from adjacent sections. The non-trimmed birds had slightly more skin damage, although the overall level was very low. Very few birds with wounds were seen and if skin damage was present it was mostly no more than some pecks or scratches. As non-trimmed beaks can cause more skin damage it was in accordance with expectation that these birds had more skin damage. The level of comb pecks also seems higher, but this was not statistically different. The overall high score for comb pecks is due to the scoring system: the highest score is given as soon as 3 (minor) pecks are present. Feather condition was not statistically different for non-beak trimmed hens compared to the trimmed birds. The high scores for keel bone deformation are also caused by the scoring system: only two categories were scored, being 0= straight keel bones or 2= deformed keel bones. The majority of hens had only minor deformations.Table 3: Results of exterior measurements

Welfare Quality® measures

To get an idea of how good or bad the Rondeel™ scored compared to the Dutch average , the data were compared with measurements carried out with the same Welfare Quality® (WQ) protocol (Welfare Quality®, 2009) on 22 commercial farms with non-cage systems in the Netherlands (no statistical analysis was done for this comparison). Two of those farms were organic and thus had non-beak trimmed birds. In the other 20 farms the birds were beak trimmed. Apart from the average of all 22 farms (called Average WQ-project), the scores of the 2 organic farms are given.On average the Rondeel™ scored slightly higher on comb pecking, but the scores were in line with the 2 organic flocks. Keel bone scores were in the same range as well as foot scores. Beak scores were higher, except for the non-trimmed birds that had scores in line with the two organic flocks. There is no good explanation for the higher beak scores for the trimmed hens, but it could be due to a slight change in the beak scores used in the earlier protocol compared to the final published WQ-protocol. Feather damage was lower compared to the average of the WQ-project and was in between the scores of the two organic flocks. Scores for skin lesions were much lower than in the WQ-project, meaning that hardly any skin damage was found.

In general one can conclude that the results of the Rondeel™ were better than the average of the 22 WQ-flocks. The scores of the non-trimmed hens were in line with the two organic flocks.

Discussion and Conclusions

One should realize that the results are only from one flock in one house with a lot of attention from all involved parties. No general conclusions can therefore be drawn concerning the results in general in Rondeel™ houses. Also this first Rondeel™ flock had only partly non beak trimmed hens, whereas the next flocks will all be non-beak trimmed. This will increase the risk of feather pecking and cannibalism. However, these first results are very promising. The non-trimmed birds did not perform a lot of pecking behaviour despite the high levels of light. Special attention needs to be paid to the cleaning of the artificial grass mat. In the second Rondeel™ house a machine is being used to frequently clean the turf. At the moment it seems this will work successfully.The Rondeel™ concept aims to combine issues like animal welfare, environmental care and consumer demand. Although the wooded fringe does not meet the requirements for free range, it does provide the birds with range possibilities, without any risk of predators. Also it is easier to control and disinfect than large areas free range. In cases of infectious diseases and the necessity to lock birds in the henhouse, the day quarters provide more possibilities to keep the birds occupied and to prevent feather pecking than other non-cage systems. Although firm conclusions cannot be drawn based on one flock, the first results in the Rondeel™ are promising and thus so far a success. No major problems have occurred and the hens adapted to the system well and made good use of all facilities.

Despite the fact that rearing was not free of feather pecking, no problems in this area were encountered. In fact this flock had better feather cover than the average seen in flocks of similar age.

References

Bos, A.P., K.H.d. Greef, P.W.G. Groot Koerkamp, Y.M.v. Hierden, M.A.W. Kommers, S.M.A.v.d. Kroon, J.A.v. Ruth and E.E.C.v. Wijk, 2004. Houden van hennen : op naar gelukkige kippen, trotse boeren en tevreden burgers. Wageningen – Lelystad, Wageningen UR, ISBN 90-6754-791-3. (Dutch publication; translated title: Keeping of laying hens – towards happy chickens, proud farmers and satisfied citizens).Bos, A.P. and P.W.G. Groot Koerkamp, 2008. Keeping of laying hens : Development and co-design of new husbandry concepts for laying hens for sustainable egg production. Presentation at 8th European IFSA Symposium (2008-07-09), Clermond-Ferrand, France.

Dierenbescherming, 2011. Beter Leven kenmerk. http://beterleven.dierenbescherming.nl

Niekerk, T.G.C.M. van, & B.F.J. Reuvekamp, 2011. Het Rondeel™ , resultaten gedrag en welzijn eerste legronde. Wageningen UR Livestock Research, rapport 473. 32 pag. (Dutch publication; translated title: The Rondeel™, results behaviour and welfare first laying cycle)

Welfare Quality®, 2009. Welfare Quality® assessment protocol for poultry (broilers, laying hens). Welfare Quality® Consortium, Lelystad, Netherlands. 114 pp.

Zusammenfassung

Rondeel™ , ein neues Haltungssystem für LegehennenIn diesem Beitrag wird das Ergebnis einer ursprünglich vom Niederländischen Landwirtschaftsministerium angeregten und von der Firma Rondeel BV zur Praxisreife entwickelten neuen Haltungssystems für Legehennen vorgestellt, das Kriterien der Nachhaltigkeit gerecht wird und Aussicht hat, von anspruchsvollen Verbrauchern akzeptiert zu werden. Der Hennenplatz im Rondeel System ist zwar teurer als im Volierensystem, aber die höheren Produktionskosten je Ei sollen durch gezielte Werbung neutralisiert werden: eine attraktive Verpackung mit dem drei-Sterne-Gütesiegel des Niederländischen Tierschutzbundes (vergleichbar mit Bio-Eiern) und einem Gütesiegel für niedrigen Energieverbrauch des Systems (aufgrund natürlicher Ventilation und anderer energiesparender Maßnahmen). Wie der Name besagt, handelt es sich um einen Rundbau, der 6 Abteile mit insgesamt 30.000 Hennen vorsieht. Das Rondeel System unterscheidet sich von anderen Bodenhaltungssystemen vor allem durch den Rundbau, der große überdachte Flächen mit Tageslicht ermöglicht. Interessenten können sich aus einem Besucherraum in der zweiten Etage und aus einem Besuchergang in einem Abteil davon überzeugen, dass sich die Hennen nach menschlichem Ermessen wohl fühlen. Der erste Durchgang war ermutigend, eine abschließende Bewertung soll erst nach weiteren abgeschlossenen Durchgängen erfolgen.