Conservation of resources and sustainability – two issues, which are becoming

more and more important against the background of a growing world population.

Economy, science and environmental protection organisations are discussing the big task of the future: to supply the world population with sufficient animal protein and at the same time, to solve distribution problems in food provision. Experts assume that the demand for animal foodstuffs will double by the year 2050. Thus, high performance as well as good efficiency of the livestock are important preconditions for feeding the world population. The limited reserves of agricultural areas require the highest possible generation of animal protein per hectare of agricultural area, whereas the production of eggs represents one of the most efficient ways in achieving that goal.

In this context, an even more efficient layer in terms of an improved feed conversion, mirrors these ongoing discussions. The LOHMANN LSL- and LB-CONVERTER should fulfil this task. Both layers are sub-lines of the well-known LOHMANN SELECTED LEGHORN (LSL) and LOHMANN BROWN layers. For several years, the breeding of these birds mainly targeted an even better feed conversion. However, this does not mean that all other selection criteria are disregarded. The challenge for the breeder lies rather in the new adjustment of the selection index. More than 20 different performance, quality and behavioural characteristics have to be evaluated anew. This is due to the fact that also for the CONVERTER lines, “only” 100 percent of the complete selection potential is available for distribution to the individual characteristics. In order to achieve the main goal of an improved feed conversion, which is the ratio of kilogram feed required per kilogram egg mass produced, a minor reduction in body weight of the CONVERTER lines was accepted. A reduced body weight decreases the maintenance requirement of the layers and contributes considerably to the improvement of feed conversion. Percentagely more feed is available for the layers in the production of egg mass. Due to the stronger emphasis of feed conversion in the selection index, there is an unfortunate as a side effect of having a slightly lower genetic progress in terms of laying performance and egg weight. However, no cutbacks in breeding were made where viability was concerned.

Capturing individual feed intake in the pure lines

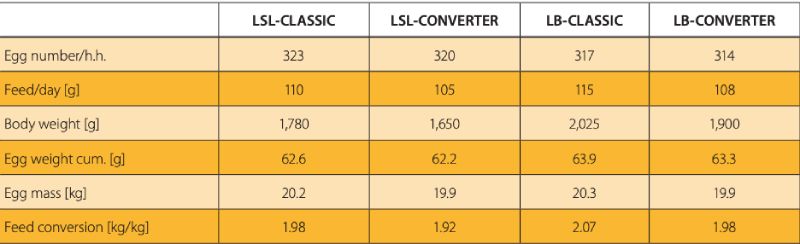

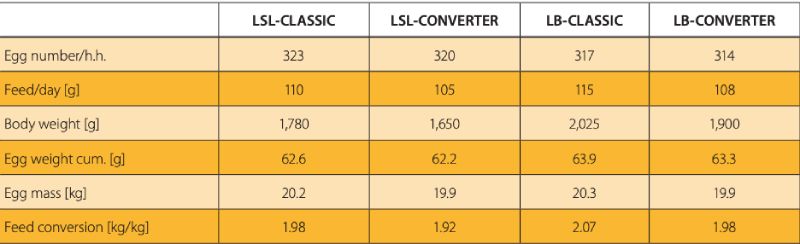

Chart 1 shows the new laying performance standards of LSL- and LB-CLASSIC and CONVERTER at 72 weeks of age in a cage system. Here, the advantages of CONVERTER layers as compared to CLASSIC lines are obvious: better feed conversion due to lower feed intake and lower body weight, although the figures also indicate that CONVERTER layers do not achieve the maximum possible egg mass production. When choosing a suitable layer, environmental conditions are crucial. Markets billing according to kilogram egg mass and not to egg quantity could obtain an economic advantage with the CONVERTER lines, as higher egg weights would be awarded additionally when billed according to egg mass, i.e. provided that the feed is always of good quality!

If the feed quality is below average, neither CLASSIC nor CONVERTER layers will be able to achieve the standard performances listed below. Countries which cannot cover their own requirements of raw materials for feed and thus, have to import feedstuff, could counteract the high-priced feed market by means of the more feed efficient CONVERTER lines. Compared to the CLASSIC lines in egg production, 60 respectively 90 g of feed per kilogram egg mass can be saved with the CONVERTER lines.

Besides egg number, egg weight and feed efficiency, the hens’ body weight can also be decisive for choosing a suitable layer. Especially in markets in which profitable prices are still obtained for spent hens, a deduction of 100 g in body weight could have an adverse effect on the economic success of the egg producer. Due to their reduced feed intake of 5 to 7 g, CONVER– TER lines have a lower body weight. This has to be considered particularly under suboptimal housing conditions. Nevertheless, good management and good feed quality provided as well as the results of a field test have demonstrated that when it comes to viability, CONVERTER lines are not inferior to CLASSIC lines.

In summary, it can be stated that due to their excellent feed conversion, LOHMANN LSL- and LB-CONVERTER layers contribute to an even more efficient usage of the scarce feed resources and to an increase in the profitability of egg production.

Dr. Matthias Schmutz and Dr. Wiebke Icken

Chart 1: Comparison of performance standards of CONVERTER with LSL/LB-CLASSIC (cage, 72 weeks)

Economy, science and environmental protection organisations are discussing the big task of the future: to supply the world population with sufficient animal protein and at the same time, to solve distribution problems in food provision. Experts assume that the demand for animal foodstuffs will double by the year 2050. Thus, high performance as well as good efficiency of the livestock are important preconditions for feeding the world population. The limited reserves of agricultural areas require the highest possible generation of animal protein per hectare of agricultural area, whereas the production of eggs represents one of the most efficient ways in achieving that goal.

In this context, an even more efficient layer in terms of an improved feed conversion, mirrors these ongoing discussions. The LOHMANN LSL- and LB-CONVERTER should fulfil this task. Both layers are sub-lines of the well-known LOHMANN SELECTED LEGHORN (LSL) and LOHMANN BROWN layers. For several years, the breeding of these birds mainly targeted an even better feed conversion. However, this does not mean that all other selection criteria are disregarded. The challenge for the breeder lies rather in the new adjustment of the selection index. More than 20 different performance, quality and behavioural characteristics have to be evaluated anew. This is due to the fact that also for the CONVERTER lines, “only” 100 percent of the complete selection potential is available for distribution to the individual characteristics. In order to achieve the main goal of an improved feed conversion, which is the ratio of kilogram feed required per kilogram egg mass produced, a minor reduction in body weight of the CONVERTER lines was accepted. A reduced body weight decreases the maintenance requirement of the layers and contributes considerably to the improvement of feed conversion. Percentagely more feed is available for the layers in the production of egg mass. Due to the stronger emphasis of feed conversion in the selection index, there is an unfortunate as a side effect of having a slightly lower genetic progress in terms of laying performance and egg weight. However, no cutbacks in breeding were made where viability was concerned.

Capturing individual feed intake in the pure lines

Chart 1 shows the new laying performance standards of LSL- and LB-CLASSIC and CONVERTER at 72 weeks of age in a cage system. Here, the advantages of CONVERTER layers as compared to CLASSIC lines are obvious: better feed conversion due to lower feed intake and lower body weight, although the figures also indicate that CONVERTER layers do not achieve the maximum possible egg mass production. When choosing a suitable layer, environmental conditions are crucial. Markets billing according to kilogram egg mass and not to egg quantity could obtain an economic advantage with the CONVERTER lines, as higher egg weights would be awarded additionally when billed according to egg mass, i.e. provided that the feed is always of good quality!

If the feed quality is below average, neither CLASSIC nor CONVERTER layers will be able to achieve the standard performances listed below. Countries which cannot cover their own requirements of raw materials for feed and thus, have to import feedstuff, could counteract the high-priced feed market by means of the more feed efficient CONVERTER lines. Compared to the CLASSIC lines in egg production, 60 respectively 90 g of feed per kilogram egg mass can be saved with the CONVERTER lines.

Besides egg number, egg weight and feed efficiency, the hens’ body weight can also be decisive for choosing a suitable layer. Especially in markets in which profitable prices are still obtained for spent hens, a deduction of 100 g in body weight could have an adverse effect on the economic success of the egg producer. Due to their reduced feed intake of 5 to 7 g, CONVER– TER lines have a lower body weight. This has to be considered particularly under suboptimal housing conditions. Nevertheless, good management and good feed quality provided as well as the results of a field test have demonstrated that when it comes to viability, CONVERTER lines are not inferior to CLASSIC lines.

In summary, it can be stated that due to their excellent feed conversion, LOHMANN LSL- and LB-CONVERTER layers contribute to an even more efficient usage of the scarce feed resources and to an increase in the profitability of egg production.

Dr. Matthias Schmutz and Dr. Wiebke Icken

Chart 1: Comparison of performance standards of CONVERTER with LSL/LB-CLASSIC (cage, 72 weeks)