Introduction

Fibre in poultry diets may sound like a rather odd topic. When I talk to egg producers about fibre from a nutritionist’s point of view, I may get a puzzled smile. All poultry and egg producers know that fibre is important for feeding horses, cattle, sheep, rabbits and even monogastric pigs and some poultry species such as geese and ratites, but laying hens? Even among poultry nutritionists the subject of fibre in poultry nutrition may still raise a polite but slightly incredulous smile.From the international literature (van Krimpen 2008, Esmail 1997, Neufeld 2008, Hartini, Choct, Hinch and Nolan 2003) and listening closely to colleagues from different countries I get the impression that this must be a very interesting subject. Research in poultry behaviour has produced a growing body of evidence showing a positive effect of crude fibre (roughage). There are also extensive indications from research and practical experience suggesting a positive effect on faecal consistency and litter quality.

A look at layer mixtures in international comparison reveals that the crude fibre content of the mixtures varies considerably among different countries, while performance levels tend to be consistently high across the board. It is also worth noting that oats, a high-fibre cereal, is being used in north-western Europe for feeding poultry, especially during the moulting, and evidently with positive results.

Restrictions on the use of raw materials with high fibre content in layer rations are more likely due to technological reasons and processes for optimising linear feed formulations rather than specific characteristics or components of these raw materials as such.

Compared with feed mixtures for cattle, pigs and other farm species, poultry diets are typically highenergy mixtures and, assuming appropriate raw materials are available, extremely high concentrations of fibre will not occur in any case.

Definition of crude fibre

In animal nutrition the terms ‘crude fibre’ and ‘roughage’ are often used as synonymous. The reason for this is that fibre is a term that has been in use for a very long time. The term ‘crude fibre’ originated from the science of feed analysis, more specifically the ‘Weender Analyse’ system of feed analysis founded back in 1864. With the `Weender’ analysis, various feed components and ingredients can be compared to get a rough estimate of digestibility. The term ‘crude fibre’ describes different structural plant materials that are insoluble in diluted acids and lyes and form a diverse group of poorly digestible or indigestible feed constituents. This might be the reason why fibre has a fairly poor reputation in poultry nutrition.Crude fibre comprises the roughage in feed raw materials, also referred to as structural carbohydrates. These plant structural carbohydrates are composed of cellulose, hemicelluloses (pentosans, hexosans) and indigestible materials, mainly lignin. The composition of crude fibre differs in each individual plant food. Structural carbohydrates are virtually impossible to digest enzymatically in the animals’ small intestine. Only the gut bacteria can digest crude fibre through fermentation by forming short-chain fatty acids and methane among other things. The proportion of cellulose and lignin in the crude fibre fraction also determines the digestibility of crude fibre or its solubility in the intestine. High cellulose and lignin concentrations mean reduced digestibility and vice versa. Wheat and maize for example have comparatively good crude fibre digestibility in monogastric animals (pigs, poultry), while oats are poorly digestible. Ruminants are very efficient at utilising crude fibre via rumen bacteria. The so-called „caecal digesters” (e.g. horses and rabbits) can also utilise dietary fibre for energy. These animal species need fibre in their daily ration for stable and healthy digestion. By-products of cereal processing such as wheat bran, wheat middlings and oat hull bran are particularly high in fibre. Some cereal varieties such as wheat, rye and maize contain little fibre, whereas husky cereals like oats and barley have higher fibre contents.

All plant fibre materials are polysaccharides, with the exception of lignin, a polymer of phenylpropane. A chemical definition is: “Roughage is non-starch polysaccharides – NSP“. Starch, also a polysaccharide and as the principal constituent in all cereal varieties the major energy source in poultry nutrition, is used here as reference. The term „insoluble NSP“ is increasingly used internationally to denote roughage such as crude fibre. They differ from „soluble NSP“ which, when present in high proportions in poultry diets, can cause the familiar problems of moist, sticky droppings and wet litter. This suggests that NSPs could reasonably be divided into „good NSPs – roughage / crude fibre“ and „bad NSPs“. When people talk about NSPs they usually mean the latter, where the use of so-called NSP enzymes is indicated to eliminate the problems mentioned. Extensive knowledge based on scientific research is available in this area and when using such raw materials in poultry diets the use of NSP enzymes has now become standard practice.br>

The acquisition of new knowledge in the area of “insoluble NSPs – roughage / crude fibre“ on the other hand is still a relatively new endeavour which, following some highly promising initial results, still requires much research work and verification of these results in the field.

Origins of crude fibre

Fibre is present in all feed raw materials and passes into feed formulations more or less unavoidably. As crude fibre makes officially no contribution to the nutritional value of poultry feed, yet has to be declared as a maximum value in many countries, the crude fibre content is included in all feed calculations and optimisations as information. As a rule, crude fibre is not subject to a minimum requirement in poultry rations and a maximum value is merely designed to ensure that the declaration is not exceeded. With different raw materials the actual fibre content can therefore range from about 2.5% in a maize-soya based mixture to 6.0 – 7.0% in mixtures based on barley, extracted sunflower meal and cereal by-products such as bran.As the fibre content is on the one hand related to the energy content of different raw materials and on the other hand deserves more attention in the formulation of poultry rations, some examples of raw materials conventionally used in various countries and regions in poultry diets are described below.

Maize

Maize, the standard raw material in poultry nutrition, has the highest energy content of all the commonly used cereal varieties. This is directly related to a low content of crude fibre of about 2 – 3%, depending on quality and origin, and a relatively low content of soluble NSP. Maize with its golden-yellow colour is regarded by poultry producers worldwide as a quality symbol for poultry feed.Sorghum, millet

Sorghum and millet are most commonly incorporated in poultry diets in North and South America, where they are grown. Nutritional value and fibre content are similar to maize. Because of its cost effectiveness sorghum was also used at fairly high concentrations (up to 40%) in poultry feed in Northwest Europe in 2007/2008.Wheat

Wheat was for a very long time the most important cereal variety for poultry feed in Northwest Europe. It has a slightly lower energy content than maize, the fibre content is similar to that of maize and the content of soluble NSP is variably higher than in maize, depending on origin and harvest year.Rye, triticale

Rye and triticale (a cross of wheat and rye) have a slightly higher content of crude fibre than wheat, the energy content is slightly lower and the content of soluble NSP distinctly higher. The use of these two cereals in poultry feed is regionally restricted to the areas where they are grown and the inclusion of suitable NSP enzymes is indicated if they make up a significant proportion of the mixture.Barley, oats

Barley and oats are also called ‘husky cereals’ and, as the name suggests, have a much higher fibre content than the cereal varieties described so far: barley about 4.5 – 7.0% and oats about 10% crude fibre. Their energy content is low and both cereal types have considerable proportions of soluble NSP. When used in poultry diets the inclusion of suitable NSP enzymes is generally recommended. Barley and oats are used in large amounts in poultry diets in the countries where they are grown, significantly increasing the crude fibre content of the mixtures. Depending on availability and cost effectiveness they are highly suitable for increasing the crude fibre content of the feed formulation.Cereal by-products, brans

Depending on the milling degree of the original cereal, all by-products of cereal milling have fairly high fibre contents ranging from about 10 to over 20%. Concentrations – including levels of other nutrients – can fluctuate widely and regular analytical checks and adjustment of the raw material matrix is an essential prerequisite for their use in poultry feed. The energy content is significantly lower than that of the original cereal because starch in particular is extracted as flour in the mill. On this basis these raw materials can provide attractive sources of nutrients and fibre, especially if lowenergy mixtures are desired, e.g. for pullets during developer phase or broiler breeders. These byproducts of cereal processing are unfortunately not available on the normal raw material market in all countries, but if available and cost effective, they are ideal sources of crude fibre for poultry diets formulated for specific purposes.Soya, extracted soybean meal

Soya beans and their processing by-products are the most important protein source in the nutrition of all farm animals worldwide. This is due to their numerous advantages compared with other oilseeds, resulting in extensive cultivation and a worldwide trade in soya products. Extracted, toasted soybean meal is widely used in feed mixtures all over the world, on a regional level also whole toasted soybeans. Soybean meal in particular has many advantages in poultry nutrition: a high protein content, a fibre content of about 3-7% depending on quality and a higher energy content than other oilseed meals. The protein and crude fibre contents of soybean meal fluctuate in opposite direction depending on quality, i.e. the higher the protein content the lower the fibre content and vice versa, and the energy content varies accordingly. An analysis of the soybean meal quality used in any ration is highly recommended as a routine measure of feed quality control.Rape, sunflowers

After soya, rape (and canola) and sunflowers are the most widely grown oilseed crops worldwide, and consequently so are their by-products: extracted rapeseed and sunflower meal. To a lesser extent, the various expellers or cakes with variable residual oil contents are also available regionally as feed raw materials. The available processing by-products of rapeseed and sunflower seeds show very wide variability across the world and regular analytical checks and adjustment of the raw material matrix are an imperative prerequisite for using these raw materials, especially analyses for crude fibre content, which is significantly higher (7 to over 20%) than in soya meal. Therefore they provide a readily available source of fibre. Since the crude fibre content is negatively correlated with the energy content, it deserves attention for that reason alone.Dried grass meals, lucerne, alfalfa

Dried grass meals are used regionally, especially in layer rations. This is mainly due to their content of natural yellow pigments and the achievable effects on yolk colour. The content of crude fibre varies depending on quality, ranging from 15-30%, and the remaining nutrients can also fluctuate considerably. If available and cost effective, dried grass meals and similar raw materials can provide a very good source of dietary crude fibre. In processed form they are spread in the litter and have shown a positive impact on poultry behaviour.Lignocellulose

Crude fibre products of lignocellulose are already well established in some areas of farm animal nutrition, including poultry diets, where promising initiatives have been undertaken in the field and in research. Lignocellulose is defined as cellulose and hemicelluloses with lignin deposits, i.e. it is lignified (woody) plant material. The advantages of these products are the standardised crude fibre content of about 50-65% depending on the product, the absence of mycotoxins and the thermal hygienisation in the manufacturing process.It is beyond the scope of this paper to describe all raw materials that are successfully used in poultry nutrition worldwide. Animal by-products are not considered here because they are not used in many countries and also tend to have a very low fibre content. But it has become clear that there is an urgent need for all raw materials used in formulating feed mixtures for poultry to be regularly analysed for their content of crude fibre (and nutrients), on the one hand to gather information about the current situation and on the other hand to be able to exploit the positive effects of crude fibre effectively, as outlined below.

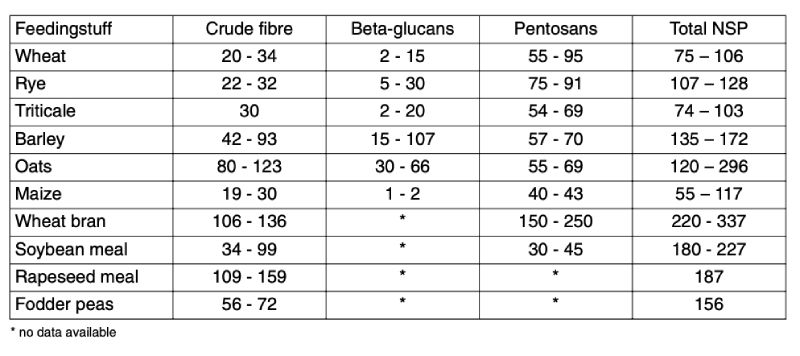

Table 1: Content of crude fibre and different NSP fractions in selected feedingstuffs in g/kg

DM (source: AWT, 2005)

How does crude fibre pass into the feed formulation?

Crude fibre, roughage and insoluble NSP pass automatically into every feed formulation, especially via plant-derived raw materials. Any animal nutritionist responsible for designing poultry feed formulations is therefore well advised to learn as much as possible about crude fibre in different feed components and their effects on the animals. Where crude fibre (also described as insoluble NSP in a different form) is currently not present as a matrix value, the first thing to do is to set up an appropriate database of all raw materials. Once this is done the crude fibre content will automatically flow into all calculations and optimisations and differences between different feed compositions can be identified. The question whether any conclusions are then drawn from this information in terms of modifying feed formulations depends on many factors, such as the availability of fibre carriers as raw material, the cost effectiveness of these raw materials and also the need or desire for targeted intervention by manipulating the crude fibre content of the mixture.Cost effectiveness is of central importance in ration formulation and evaluation of raw materials as costs must always be considered. Cost effectiveness denotes the value of a raw material e.g. in Euros or Dollars at which it is initially included in the formulation during feed optimisation with a view to reducing the overall cost of the mixture. The cost effectiveness of a raw material is determined by its nutrient content and its absolute price within a specific formulation in competition with alternative raw materials. Cost effectiveness in this context is completely different from a high or low absolute price of a raw material and can ultimately only be determined by using an optimisation program.

As already indicated in the description of individual raw materials, if maize and soybean meal are the only basic raw materials available for a feed formulation, the result will be a relatively low fibre content of about 2.5 – 3%. In this situation there is virtually no prospect of achieving a higher fibre content, which is a disadvantage when formulating an optimal developer feed for example. Faced with this situation it is advisable to check again whether any other raw materials might be available, e.g. DDGS, a raw material with a significant crude fibre content of approximately 5-10% depending on origin and quality which accrues as a by-product of bioethanol production. By introducing a minimum restriction for crude fibre in the optimisation it is possible to test the possible extent of increasing the fibre content.

In other countries and regions, such as Scandinavia or Spain, the ready availability and cost effectiveness of barley, in Scandinavia also oats, automatically results in crude fibre contents of about 4.5 – 6.5% in layer rations. If these raw materials are available, perhaps with additional cereal byproducts, the desired fibre content can easily be achieved via ration optimisation. In countries where different raw materials with varying nutrient and fibre concentrations are usually available, cost effectiveness is the main factor in deciding whether or not to include the raw materials in the formulation, thus enabling the experienced nutritionist to achieve a specific crude fibre content in the ration.

A recent example from Western Europe may illustrate this point. During the period from mid-2007 to about mid-2008 changes in the cost effectiveness of corn and wheat resulted in layer rations almost entirely based on maize and soya, following several decades with wheat and soya as main components. Without setting a minimum restriction for crude fibre in optimisations, the fibre content in the finished feed would decline markedly.

Other sources of crude fibre in poultry diets are the different oilseed meals, which are primarily incorporated into the mixtures to cover the protein requirement. While soybean meal (especially highprotein grades) bring little fibre into the formulation, the use of extracted sunflower seed meal and rapeseed meal results in significant amounts of crude fibre in the formulation. Here too, a specific, stable fibre content can be maintained via the optimisation program, provided the relevant raw materials are available and cost effective.

Without the availability and cost effectiveness of suitable raw materials, it may be virtually impossible to achieve a specific crude fibre content in the formulation. In this case an alternative solution would be products based on lignocellulose for optimising the crude fibre content, entirely with insoluble NSP, an approach which has already proved effective in practice and is discussed in more detail below. Due to their very high fibre content these products have the advantage of requiring relatively little space in the formulation in order to achieve a marked increase in the crude fibre content of a formulation. The same is true if the fibre content of more highly concentrated mixtures is to be increased, for example a nutrient-dense layer starter ration or broiler feed. If normal fibre carriers such as bran or extracted sunflower seed meal are included in the optimisation program in competition with a crude fibre concentrate, this may turn out to be highly cost effective and result in an overall cost reduction. Any modification or optimisation of the formulation to achieve a given crude fiber content should preferably be achieved without affecting the levels of the remaining nutrients in the ration, especially the energy content. If this is not achieved, adding a raw material with higher fibre content will educe the nutrient content of the ration, which may well result in performance reduction and reinforce traditional negative attitudes towards crude fibre. But with expert ration optimisation this is unlikely to happen. Modifying a layer ration to achieve a specific, slightly higher crude fibre content while maintaining the energy content can involve a slightly increased use of fats and oils. This is very welcome as it improves the acceptance of a meal-type feed for hens, binds dust and because a higher energy contribution from fat and oil provides numerous nutritional benefits for high-producing laying hens.

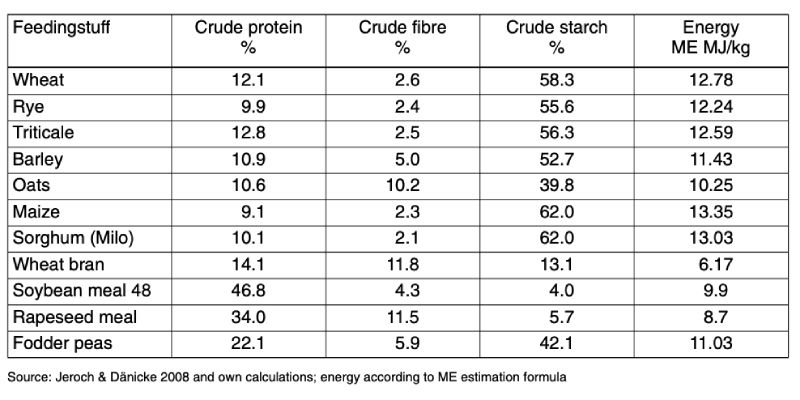

Table 2: Nutrient content of selected feedingstuffs (figures at 88% DM)

Practical experience with fibre in layer diets

Looking at diets for laying hens in international comparison we find that fibre is not a negative element and has no adverse effect on layer productivity. Even though the majority of poultry kept for commercial purposes are fed maize/soya-based rations, there are still many countries with intensive poultry production where this is not the case. In these countries mixtures based on wheat, triticale, barley and even oats are formulated and protein sources, along with soybean meal, include extracted sunflower seed meal, rape or canola products, other legumes such as peas or field beans or other diverse plant-derived protein carriers such as dried grass meal. There is also a wide range of other raw materials that can potentially be used for feeding laying hens. The resulting mixtures may well contain up to 7% fibre in the classic sense, distinctly more than in the maize/soya mixtures. Allowing for the problem of soluble NSP, which require the use of NSP enzymes, and insoluble NSP (crude fibre), these diets are entirely equivalent to maize/soya-based mixtures in terms of productivity and egg quality of modern layer hybrids. Very often it is found that rations with higher fibre content, i.e. more than 3.5 – 4.0%, stabilise the gut, resulting in drier litter, especially in non-cage systems. Even in battery systems a more stable gut situation will reduce the proportion of dirty eggs.Reports in the literature (Rezaei,Torshizi and Rouzbehan 2008) and practical experience in several countries suggest that layer rations with higher fibre content can reduce the ammonia concentration in the air. This has a positive effect on the health of the birds and improves working conditions in poultry houses. Excessive ammonia levels are a frequent problem especially in floor systems.

From my own practical experience, I can report that diets with higher fibre content have a favourable effect on laying hens in non-cage production systems. This observation has been confirmed by recent scientific studies (van Krimpen 2008; Hartini, Choct, Hinch and Nolan 2003) and should be taken into account as a contribution to ensure continued success of the egg industry when adapting production systems to consumer preferences for eggs from non-cage systems.

In the rearing of laying hens the dietary fibre content is also of key importance during the pullet or developer phase (approx. weeks 9 – 16). Provided the development of the chicks during the starter phase (up to week 8) was successful, a nutrient-reduced ration can and should be fed during the pullet phase in order to enable the pullets to grow slowly into physically and sexually mature laying hens. The nutrient reduction in the developer diet refers to the protein and amino acid content rather than the energy content. If available, raw materials with a lower nutrient density and higher fibre content could be introduced into the ration. In many countries these raw materials are also often more cost effective than cereal and soybean meal and can thus help to reduce feed cost in the pullet phase, the time of highest feed consumption during the rearing phase. A higher fibre content in pullet feed (e.g. above 5.5%) also helps the young birds to get used to eating a larger volume of feed. The inclusion of highfibre components (e.g. cereal by-products) slightly reduces the specific weight of the feed, forcing the pullets to spend more time eating.

Training pullets for a high feed intake capacity during rearing is the key to adequate feed intake at the start of the laying period. At this critical time many flocks have an inadequate feed intake, leading to depressed productivity and failure to achieve peak performance. Undernourishment of hens during this phase may also cause poor performance and health problems later on, such as fatty liver syndrome. It has been shown in scientific trials (van Krimpen 2008; Harlander-Matauschek 2007) that an increased content of crude fibre (insoluble NSP) additionally has a favourable impact on behavioural characteristics of hens by reducing the tendency to aggressive pecking and cannibalism. As a rule, when efforts are made to increase feed intake the use of meal-type feed and feed with a higher content of insoluble NSP reduces the tendency towards abnormal behaviours or vices, an important consideration in terms of animal welfare. There is also a direct correlation between dietary fibre and maintenance of an intact plumage, which must be a fundamental aim of any commercial poultry operation.

If a wide range of raw materials is available, it is relatively simple to optimise feed formulations by setting maximum and minimum levels for crude fibre. To what extent this is possible depends on many factors, not least the cost of the formulation, if crude fibre “is not calculating by its own”, as the nutritionist sitting at his optimisation computer tends to put it. Experiences gathered by animal nutritionists in many countries with formulations optimised for a higher crude fibre content should be an incentive to introduce it even in countries where it has not been practised previously. But it is not possible to give a generally valid recommendation as the availability of suitable raw materials and their relative cost effectiveness can differ significantly.

A question that is still entirely unresolved is the impact of fibre, if any, on the gut flora. It is well known that a healthy, species-specific gut flora is essential for stable digestion and efficient nutrient absorption. It is the basis of the body’s ability to fight infections and the competence of the gut as an inductive site for immune responses. We know from other species that the gut flora can be influenced by stabilising it through nutrition and diet, but very little research has been done in this area with poultry. The author has reports from the field suggesting that feed which has been optimised specifically for gut health via the crude fibre content might potentially have an effect on the clostridial problem. But further practical experiences and research work are required in this area.

It has already been mentioned that the options for accurately adjusting the crude fibre content in ration formulation are very limited if suitable raw materials are either unavailable or not cost effective. In this situation, the use of fibre carriers based on lignocellulose provides an alternative. Initial published results from the field on this subject in poultry are already available, following successful use of these products in the nutrition of pigs, rabbits and household pets. The impact of these fibre concentrates (50 – 65% crude fibre) on faecal stability and litter quality is usually instantly evident. Given the additional stabilisation of the gut and the resulting improvement in nutrient absorption, an effect on the animals’ performance is a logical consequence. Fibre concentrates offered on the market do not have the often wide fluctuations in the nutrient content found in normal fibre carriers (e.g. brans, dried grass meals) and provide guaranteed hygienic quality, such as absence of contaminants and mycotoxins. They require less space in the ration formulation to achieve a consistent increase in the fibre content of the diet. It may even be possible to achieve a cost advantage if a minimum restriction has already been incorporated in the optimisation program.

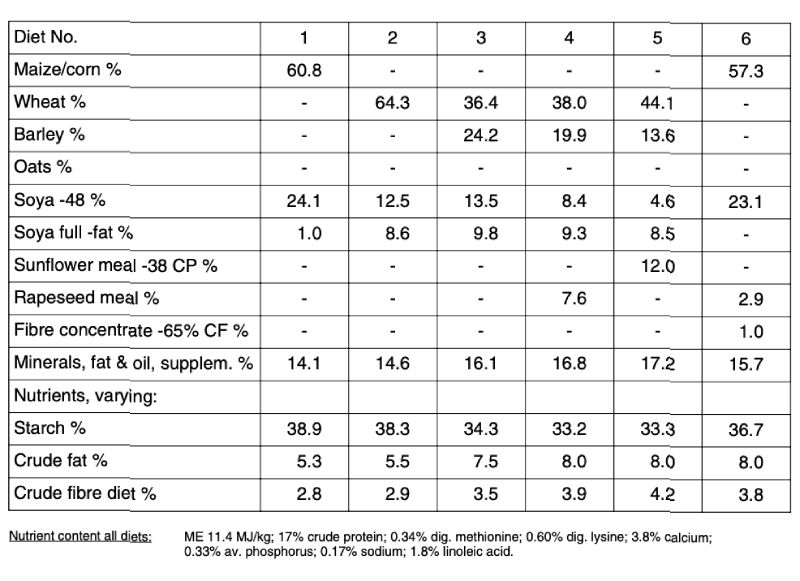

Table 3: Layer diets with different raw materials and varying content of crude fibre (and

crude fat), optimised for constant nutrient content.

Discussion

Fibre has no direct nutritive benefit in poultry nutrition and has until now been regarded as `useless roughage´. Diets based on maize and soya products predominate worldwide and are considered ideal for poultry. But many countries have had very good experience using other raw materials with higher fibre content (e.g. wheat, barley, oats, bran, rape products, sunflower seed products) in poultry diets. Compared to conventional maize/soya-based mixtures, these diets have a significantly higher content of crude fibre (insoluble NSP). This suggests that fibre is by no means harmful for poultry. Many countries have had very positive results from using raw materials with higher fibre content. This has changed the perception of crude fibre in layer diets (and also in chick starters); it is no longer regarded as just roughage and is now deliberately incorporated into poultry rations via the optimisation process. The effects have generally been a positive impact on faecal consistency and litter and a reduced percentage of dirty eggs.Results from commercial farms suggest that monitoring or deliberately manipulating the fibre content can be highly beneficial if the aim is to optimise the diet for `gut health´. There is mounting evidence that fibre has a positive effect on behavioural characteristics of poultry. Scientific studies on this subject are also increasingly appearing in the international literature. In view of the current trend in the EU and other countries to change from conventional battery cages to alternative systems for laying hens, it is important to determine to what extent diets with optimal fibre content can help to control aggressive pecking in non-beak treated hens in floor systems.

To what extent fibre is actually included in layer diets will depend on the availability of suitable raw materials. The options are limited where classic maize/soya diets are used. But awareness of the benefits of fibre might encourage animal nutritionists and feed manufacturers to actively search for raw materials not previously used, in an attempt to introduce these into established formulations. One such „new“ raw material is DDGS (dried distillers grains with solubles), a by-product of worldwide bioethanol production. Others include all by-products of cereal processing for food use such as brans and middlings and by-products of oil extraction from sunflower seed or rapeseed. Where these or similar raw materials are not available, the use of crude fibre concentrates based on lignocellulose provides an alternative. Products of this type are of standardised quality with a very high hygiene status and are free of undesirable contaminants such as mycotoxins.

Initial results on the use of lignocellulose-based products in broilers, turkeys and laying hens have recently become available. They confirm the basic findings obtained with conventional fibre carriers but also open up new possibilities, including cost-optimal formulation of layer diets.

Conclusion

Maize and soybean meal are considered worldwide to be the standard raw materials for laying hen diets. In many regions where these materials are either unavailable or not cost-effective farmers have been using alternative raw materials, which inevitably leads to a higher fibre content in layer diets compared with the standard maize/soya based formulation. The productivity of flocks fed these diets is at least equal, and in some cases even superior, to the maize/soya diets. Stabilisation of the digestion, resulting in drier droppings and improved litter, is often a welcome secondary effect. Research results indicating a positive nutritional effect and a favourable impact on behavioural characteristics of laying hens by feeding diets with higher levels of crude fibre (insoluble NSP) are increasingly reported in the international literature (van Krimpen 2008; Harlander-Matauschek 2007; Hartini, Choct, Hinch and Nolan 2003). If conventional fibre carriers are unavailable or not cost effective for ration formulation the use of crude fibre concentrates based on lignocellulose provides an interesting alternative for adjusting the fibre content (insoluble NSP) of a feed formulation. Practical experience with manipulating the fibre content of diets for laying hens and growing chicks have had the following results:- Pullets learn sufficient feed intake to overcome the critical period of peak production

- Effect on the gut flora through `feeding for gut health´

- Stabilisation of digestion with a positive effect on litter condition and house climate

- Reduced percentage of dirty eggs due to sticky droppings

- Favourable impact on behavioural characteristics, such as aggressive pecking and cannibalism

Optimizing the fibre content is an important aspect of formulating diets of laying hens. Further research into the effect on poultry behaviour in general and the impact of the content of insoluble NSP (crude fibre) and the different crude fibre fractions on digestive physiology are required to verify the experience gained in the field.

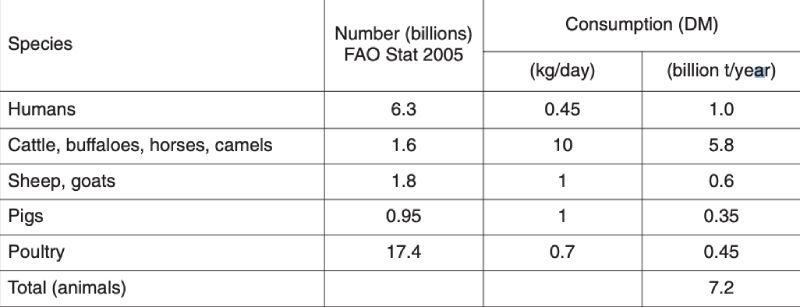

Table 1: Estimated dry matter (DM) consumption by humans and farm animals.

- Animal ecology: Does behavioral research take into account describable, fundamental needs of the animals to be fed?

- Environmental ecology: What effects do feed systems have on the environment?

- The relationship between local and national, European and global “solutions” for using protein resources.

- Consideration of the rights of people to participate and to fulfill their potential in economically disadvantaged areas on Earth.

AWT, Arbeitsgemeinschaft Wirkstoffe in der Tierernährung (2005): Enzyme in der Tierernährung (Enzymes in Animal Nutrition), 55pp.

Esmail H.M. (1997): Fibre in Nutrition. Poultry International, July 1997.

Harlander-Matauschek A. (2007): Untersuchungen über die Motivation des Federpickens bei Legehennen. Hohenheim, May 2007.

Hartini S., M. Choct, G. Hinch and J. Nolan (2003): Effect on diet composition, gut microbial status and fibre forms on „Cannibalism in Layers“; Australian Egg Corporation Limited, April 2003.

Jeroch, H. and S. Dänicke (2008): Faustzahlen zur Geflügelfütterung. In: Damme & Möbius (Ed.) Geflügeljahrbuch 2008, 148-176.

Neufeld K. (2008): Nahrungsfaser in der Nutztierfütterung, Kraftfutter Jan. 2008

Neufeld K. (2008): Mehr als nur Rohfaser. Schweinezucht und Schweinemast, SUS Feb. 2008

Pottgüter, R. (2009): Rohstoffeinsatz in der Geflügelfütterung – Alternativen zu Mais und Soja. In: Geflügeljahrbuch 2009, 27-36. Ulmer. ISBN 978-3-8001-5771-6.

Rezaei M., K.Torshizi and Y.Rouzbehan (2008): Effect of processed and conventional fibre supplementation on performance, organ weight and immune response of broilers. XXIII World’s Poultry Congress 2008, Brisbane, Australia.

van Krimpen M. (2008): Impact of nutritional factors on eating behaviour and feather damage of laying hens. Diss. Wageningen, Sept. 2008.

Zusammenfassung

Rohfaser wurde bisher in der Geflügelernährung wenig beachtet. In diesem Beitrag wird deutlich, dass Rohfaser zwar keinen „Nährwert“ im klassischen Sinn hat, aber erwünschte Nebenwirkungen bei richtiger Dosierung haben kann: (1) die Entwicklung eines optimalen Verdauungstraktes in der Junghennenaufzucht hilft in der kritischen Phase der Legespitze, genügend Futter aufzunehmen; (2) eine stabilere Darmflora trägt zu einer besseren Kotkonsistenz bei und zeigt sich u.a. durch bessere Einstreu bei Bodenhaltung und weniger Schmutzeiern in allen Haltungssystemen; und (3) gibt es Hinweise, dass mit erhöhtem Rohfasergehalt die Neigung zu Federpicken und Kannibalismus verringert wird – vorausgesetzt, das Fertigfutter bleibt ausgewogen in allen essentiellen Nährstoffen, insbesondere limitierenden Aminosäuren.Deutschsprachige Leser seien auf einen Beitrag des Autors im Geflügeljahrbuch 2009 hingewiesen, der nicht nur, aber auch das Thema Rohfaser im Zusammenhang mit der Auswahl von Rohstoffen für die wirtschaftlich optimierte Geflügelfütterung ausführlicher behandelt.