Modern poultry production demands precision. Gone are the days when intuition alone could guide management decisions. Today, benchmarking and data-driven analysis are essential tools for optimizing performance and ensuring profitability.

At LOHMANN BREEDERS, we combine comprehensive data collection with advanced analytics to deliver actionable insights for producers worldwide.

Field data analysis goes a step further by enabling:

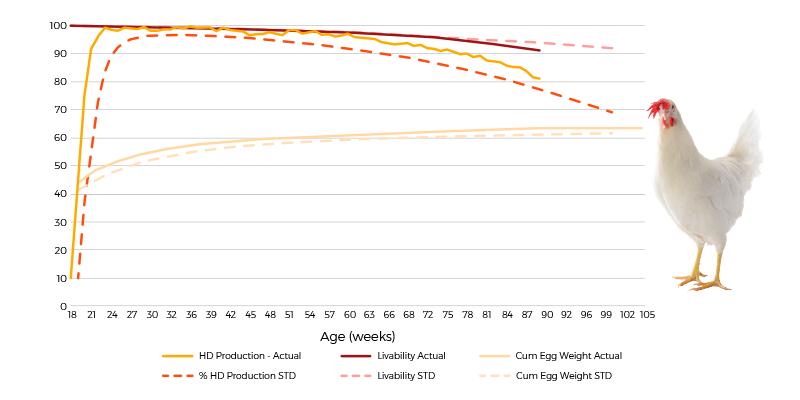

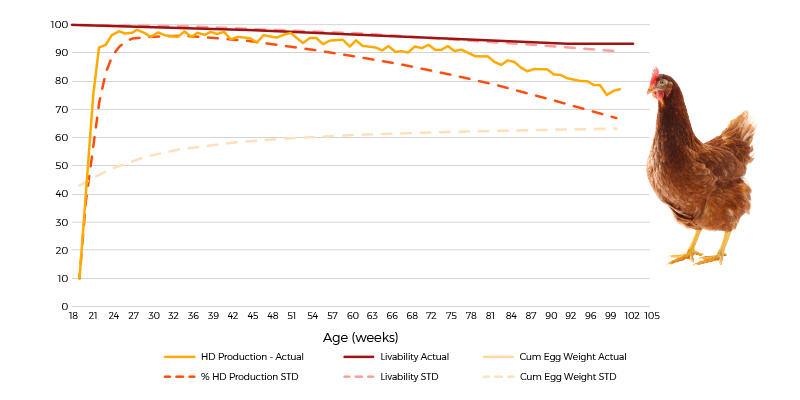

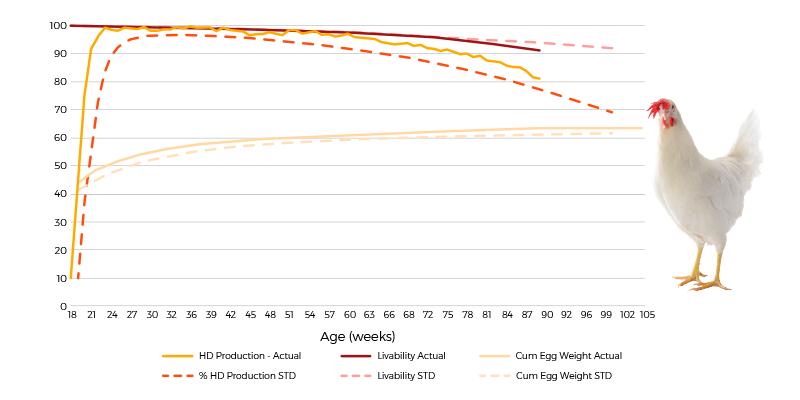

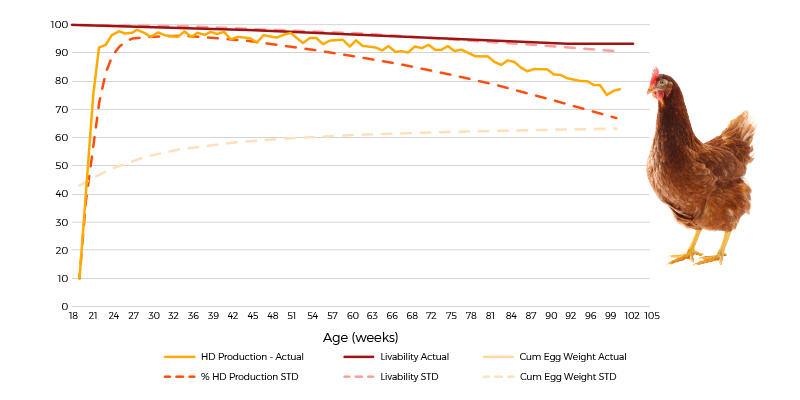

Reaching over 500 eggs before 100 weeks is no longer a milestone with livability as good as 94% and over 50 weeks above 90% hen day production for LSL commercials.

On the other hand, even LOHMANN BROWN birds are able to reach over 500 eggs per hen housed in cage conditions, even in hot climate regions where we balance good management practices and hands-on technical service.

Understanding these variables help producers fine-tune management strategies and maximize profitability.

The interaction of these variables gives egg production a finetuning tool to optimize the operation.

Our predictive models already achieve significant statistical confidence.

At LOHMANN BREEDERS, we combine comprehensive data collection with advanced analytics to deliver actionable insights for producers worldwide.

Why Benchmarking and data analysis matter

The performance of laying hens depends on a complex interplay of genetics, nutrition, housing system, environmental and health factors as well as management practices. Without structured data, these relationships remain unclear, and decision making may turn out biased. Benchmarking allows producers to:Compare their results against industry standards

Identify strengths and weaknesses

Implement targeted improvements

Field data analysis goes a step further by enabling:

Early problem detection (e.g., feed intake, mortality)

Optimization of management strategies

Evidence-based decisions for long-term success

Key insights from benchmarking

Recent benchmarking studies highlight the genetic potential of LOHMANN breeds under diverse conditions across the globe.Reaching over 500 eggs before 100 weeks is no longer a milestone with livability as good as 94% and over 50 weeks above 90% hen day production for LSL commercials.

On the other hand, even LOHMANN BROWN birds are able to reach over 500 eggs per hen housed in cage conditions, even in hot climate regions where we balance good management practices and hands-on technical service.

Extending production to 100 or more weeks showcases genetic robustness and the potential for longer laying cycles. We often see customers keeping single cycles of 120 weeks getting close to 600 eggs per hen house in 2025. When properly managed even more eggs per hen housed are yet to come!

Performance drivers

Data from flocks hatched in 2020–2022 reveals that the following factors significantly influence outcomes at different rates:Housing system: open houses and climate controlled

Feed supplier: different suppliers lead to significant different outcomes

Stocking density: normal ranges of birds per area should be respected for enhanced pay off

Beak treatment: different approaches can have better results

Hatch season: linked to housing, it can be an effect playing important role in egg production

Understanding these variables help producers fine-tune management strategies and maximize profitability.

The interaction of these variables gives egg production a finetuning tool to optimize the operation.

The Future: AI and Big Data

LOHMANN BREEDERS is pioneering the use of advanced analytics in poultry production:Artificial Intelligence and Machine Learning

Big Data and multivariate analysis

Ethical data handling (fully anonymized)

Our predictive models already achieve significant statistical confidence.

These tools enable automation, re-skilling, and precise recommendations for optimal performance.

Conclusion

Benchmarking is more than comparison—it is a strategic instrument for continuous improvement. Combined with robust data analysis, it empowers producers to:Measure – Analyze – Act

Reduce waste and improve efficiency

Adapt genetics to local conditions

Call to Action

Share your field data with us and help shape the future of layer production.Data = Insight = Results.