Hatchery contamination can be one of the most serious challenges for the entire production management, since the hatchery is the main hub of the poultry industry, connecting breeder farms to commercial farms.

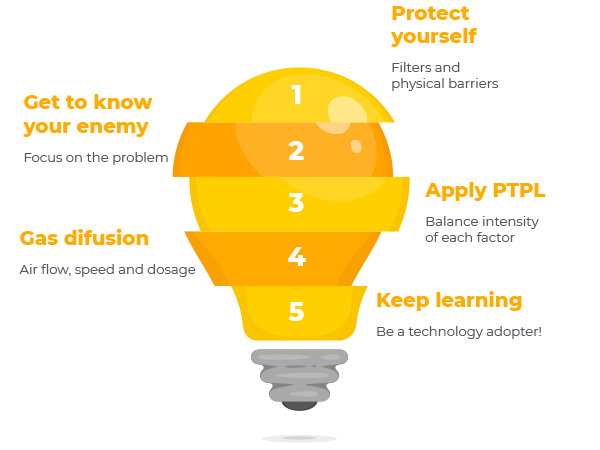

Preventing contamination within a hatchery depends on knowing 4 core principles:

- Physical Protection

- Knowing Your Enemy

- Power, Temperature, Product, Lapse

- Gas Diffusion

Physical Protection

The best way to prevent airborne contamination in a hatchery begins with careful planning during the construction phase, including the building to take advantage of prevailing winds and always following the egg-to-chick flow in accordance with external airflow. Once the hatchery is built, protective measures can still be implemented, such as physical barriers, either natural (trees) or man-made (walls).Regardless of the hatchery’s orientation, it is essential to maintain at least four separate flows and to avoid cross-contamination at all costs — not only for personnel, but also for equipment and especially ventilation.

Ventilation also helps to keep trays and baskets dry after cleaning and disinfection, as this will ensure no re-contamination occurs. To dry the room and equipment efficiently, set the ventilation system to the lowest temperature it can maintain.

This will reduce water vapor in the air by condensation and will make absolute humidity down by condensation out.

Immediately after washing, and before disinfection, place an air heater blower aimed directly at the trays – never after disinfection, as this could blow disinfectant off the trays and baskets.

This will evaporate the water, remove it from the tray and basket surfaces, and allow the HVAC system to remove it from the air.

Last but not least, in hot and humid summer conditions, avoid fresh air intake, since it can carry far more water vapor than the desired indoor climate (e.g., 25°C / 50% RH).

Even outside air at 40°C and 25% RH can bring in more water than desired indoors.

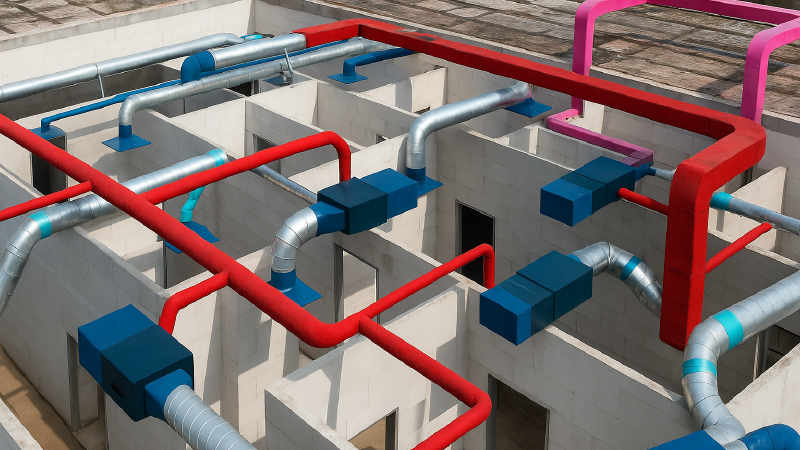

Another common source of contamination is ductwork for both fresh and exhaust air.

We recommend minimizing the number of ducts over machines and within the building, as these areas can become dirty and damp over time, creating ideal conditions for microbial growth, particularly mold.

Instead of ducts, consider plenums large enough for a person to stand and walk through. Airspeed can easily be adjusted in such plenums for proper distribution across the different rooms in the hatchery.

Knowing Your Enemy

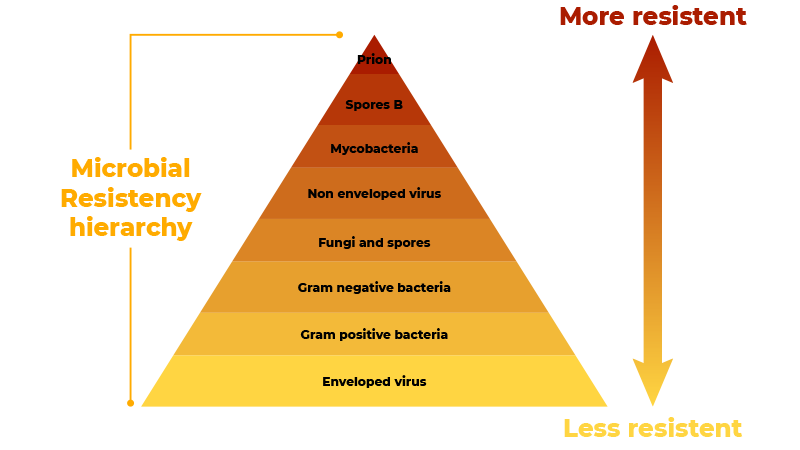

Keeping the hygiene status of a hatchery is like an ongoing battle. One of the most important things is to get to know your enemies i. e. to understand exactly which microorganisms you are fighting. In a hatchery, fungi (e.g., Aspergillus sp. and Cladosporium sp.) and spores are more resistant than gram-negative bacteria (E. coli, Pseudomonas, Proteus sp.) and gram-positive bacteria (Staphylococcus sp.).Identifying the specific microorganisms affecting your hatchery’s health is essential before deciding on control strategies.

Some newer molecules have recently entered the market, such as Chloramine T, Anolytech, and ortho-phthalaldehyde. Whether these products are available in your country or not, the most important factor is to check their actual efficiency against the microorganism strains you are dealing with.

We therefore strongly recommend performing a Minimum Inhibitory Concentration (MIC) test for every new batch of disinfectants received in your hatchery.

Please add this after Lapse (PTPL)

Power refers to the application of physical force — by machine or people — during cleaning. This might involve scrubbing a hatcher wall, applying high-pressure water to a setter tray, or cleaning any other surface that requires routine attention. Applying enough power at the start of the cleaning process makes the following PTPL steps easier — and the reverse is also true.Today, numerous highly efficient machines can replace much of the labor-intensive work involved in this process, and we should consistently rely on these machines for the most demanding hatchery tasks. In any cleaning procedure, power should always be the first consideration.

However, a frequently overlooked factor is the growth temperature range of microorganisms. Mesophiles — a group of bacteria and fungi — grow best between ~15°C and 45°C, with peak growth at 37–38°C. This is exactly the range in which incubation occurs! These microorganisms have evolved alongside poultry for millions of years, adapting to the same optimal conditions.

Foam is often preferred for cleaning because it makes application visible, but bubble size matters: small bubbles cling to surfaces, while large bubbles push detergent away.

Killing microorganisms is a multi-step process — disrupting membranes, breaking proteins, damaging nucleic acids, and altering metabolic pathways, among others. This takes time, especially in vivo, so allow at least 20 minutes for detergents and disinfectants to work.

Gas Diffusion

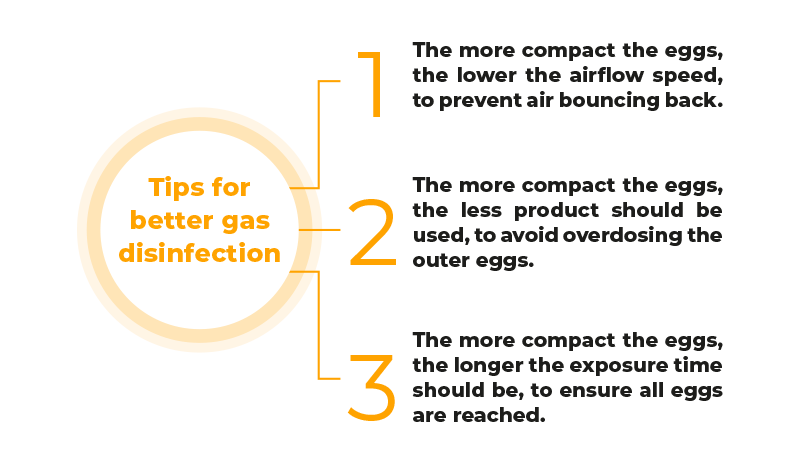

When disinfecting (not only eggs), it is important to understand the basic principles of gas diffusion. For optimal diffusion, we need the correct dosage (concentration), air temperature, and ventilation (distribution). Fast, even distribution of the active ingredient is crucial, especially with aldehydes like formaldehyde, which can cause embryo mortality if poorly managed.When eggs are packed too closely, airflow between them is restricted. Using setter trolleys and trays allows easier air passage, but factors such as airflow speed, exposure time, and contact area must be carefully balanced.

With these measures in place, you will keep your hatchery better protected against all types of microorganisms.

If any question arises, it will be a pleasure for the Global LOHMANN BREEDERS Technical Service Team to serve you and your company.

Incubation

Incubation