Introduction

The logo of the World Poultry Science Association (WPSA) contains three key words: education – organization – research. Many people think of education in terms of public schools and universities, but equally important is continued “learning by doing” and keeping up with international developments connected with the field chosen for a professional career. The WPSA has more than 7000 members with branches in some 70 countries. An important element of the organization is the Federation of European WPSA Branches, with more than 3000 members in 28 countries, of which Germany has the largest branch with more than 350 members. As a major contribution to continuous education, the European Federation of WPSA established “Working Groups” which maintain networks among colleagues with common interests and organize symposia from time to time to update each other on current research and new results. Working Group “Poultry Welfare and Management” (WG9) has contributed substantial scientific information on alternatives to cage management of laying hens, which has also been used by the EU and national legislation in defining minimum requirements for housing systems. During the 8th European Symposium on Poultry Welfare (18-20 May in Cervia, Italy), colleagues from many countries will update each other on latest developments in response to the ban on conventional cages in the EU beyond 2012.Developments in Germany are of special interest in this context. Due to a liberal import policy and tougher welfare regulations for domestic egg production than in other countries, Germany has been the largest importer of table eggs (mainly from neighbouring Netherlands) for many years. Presently the German egg industry struggles with the national ban on cages effective in 2009, three years ahead of the EU deadline. At the end of 2008, about 40 million hens produced 70% of domestic egg consumption; predictions are that only 30 million hens will be left at the end of 2009 when the current transition period ends.

Shell eggs sold in German food outlets have to be individually stamped to identify country of origin, type of production (0 = organic; 1 = free range; 2 = barn; 3 = cage) and farm number to assure complete traceability.

The German WPSA branch has offered the egg industry support during a critical period of adjustment by helping to inform interested consumers and the general public about the new management systems for laying hens, using the competence of its members and the internet to make existing knowledge available and analyzing data from audited records. This report will try to explain the reasons for this commitment and how we plan to proceed in the years ahead.

Management systems for laying hens in Germany conforming to 2009 regulations

Detailed regulations for the four types of management can be found on the website of the German WPSA Branch www.wpsa.de. Several equipment companies are offering their specific solutions within these legal limits, but it is virtually impossible to get independent and reliable information to compare different models in terms of all relevant criteria. Potential investors have many questions which would need to be answered before a return on investment can be predicted for the next 15 years, during which the equipment is usually depreciated. In the end, decisions are usually made on (1) cost per hen place (the only hard figure); (2) expected saleability and margin per egg from a given management system; and (3) recommendations by known contact persons or the sales representatives of equipment companies. Major “unknowns” are egg prices for different categories, the adaptability of specific flocks of laying hens (genetic strain and rearing environment), and decisions of major players in the food market which type of eggs they will list.The demand for organic and free range eggs has been increasing during past years, but it should be clear that this will remain a niche market. Rapid expansion of production in excess of demand could easily eliminate the current margins. Consumers may also question the free range status during times when hens have to be kept inside to minimize HPAI and other health risks.

Barn eggs can be produced in single-tier and multiple-tier systems. Some of these systems (“Volieren”) reach similar bird densities per m³ housing space as enriched cages and require considerable management skill to get good results in terms of clean, saleable eggs. It seems doubtful whether enough barn eggs will be produced in Germany to make up for the loss of cage eggs, creating opportunities for additional imports. Also, people who object to cage management will probably take some convincing before they accept these systems as satisfactory solutions.

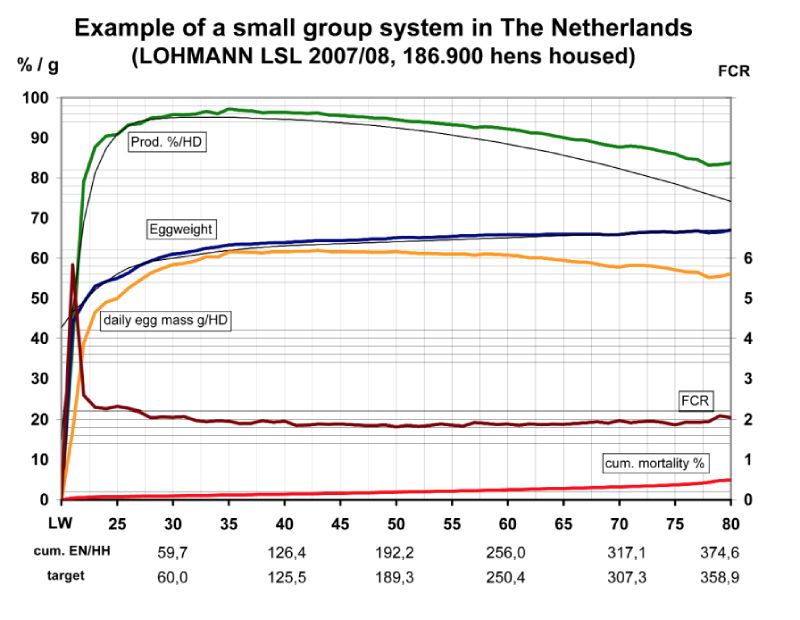

Cage eggs can still be imported after the ban on conventional cages becomes effective this year. As a compromise in response to pressure from organized animal welfare to abolish all types of cages and opposite arguments of the egg industry to save jobs for German producers, it was decided by the German authorities to accept “Kleingruppenhaltung” (small group management) as a production system conforming to German animal welfare laws. This system is based on extensive research at different scientific institutions in cooperation with the industry. While retaining advantages of conventional cages (efficiency of production, good air quality, clean eggs, easy to manage), it offers substantial improvements for hen welfare (more space, a nest, scratch area to ‘sandbathe’, perches to rest on). Recent field results from The Netherlands documented in figure 1 (Flock, 2009) confirm positive experience in Germany on several test farms.

Figure 1

What does “Tiergerechte Haltungsform” mean?

Earlier this year, a new organization “Verein zur Förderung nachhaltiger und tiergerechter Haltungssysteme” was established to promote sustainable and animal-friendly egg production in Germany. Members of this organization may use the “seal” shown in figure 2 on egg cartons and/or individual eggs from their own production to promote eggs – provided they participate in an auditing system and supply certain data for statistical analysis. The WPSA has listed details of criteria which must be confirmed during auditing.All types of production allowed in Germany after 2009 will be represented in the scheme, hopefully with sufficient numbers of flocks to enable scientists to draw valid conclusions, which can then be used to further improve management practices.

During the starting phase of the scheme, the WPSA had to make its intentions clear:

(1) to contribute to the transparency of egg production by offering the general public and individual egg consumers information on egg production in different production systems; and

(2) to provide statistical summaries of field data which may be used to learn from the best flocks in each system how to improve the management of laying hens.

Figure 2: Logo which may

be used on egg cartons or

stamped on eggs to identify

participation of the producer

in the WPSA data base

Some critics of the scheme are questioning whether a scientific organization like the WPSA should run the risk of having the “seal” misused for advertising before audited records can be analyzed. Initially, the participants in the scheme can only subscribe to the intention of sustainable and animal-friendly egg production and provide reliable data from their own egg production. To realize the second intention will require time to collect and analyze data and general observations. The text around the seal (“von der Deutschen Vereinigung für Geflügelwissenschaft e.V. begleitet”) indicates that the German WPSA is committed to keep an independent eye on the different systems by analyzing and interpreting the information which will be supplied by the industry partners.

Not surprisingly, the first questions regarding the involvement of WPSA in this information campaign came from organizations which have been arguing against laying cages. Will they admit there is a difference between conventional cages and the Kleingruppenhaltung which meets German animal protection laws? It will be difficult for them to use “tiergerecht” in the broader sense to include modern ‘cages’ which provide all components considered essential by ethologists (sufficient space to move around and escape, a darkened nest, a kind of sandbath to scratch, and perches to rest on). The truth to be explained by scientists is certainly more complex than the simple message some animal welfarists prefer: “a cage is a cage”.

Consumers and producers can both benefit from the “WPSA-Seal”

Egg consumers and the interested general public are the first target group for this initiative. It is hoped that more and more consumers will note the new seal on egg cartons and visit the WPSA homepage to find out more about animal welfare standards in different systems. The information on the WPSA website will be presented in easy to understand language, between “too scientific” (more technical and detailed than most people need) and “promotional“.Egg producers will hopefully convince themselves that eggs with this “seal” can be sold in food stores with a sufficiently higher margin to recover the cost of record keeping and auditing. However, there is a third party in the food chain between producers and consumers:

Food stores, especially the decision makers of discounters, are major players in the egg business. They decide the range of products from which consumers can actually choose. In the highly competitive food business, the management has to focus on monthly margins per m² shelf area, which depends on the number of comparable products the buyer can choose from. Most German egg consumers are relatively flexible in what kind of eggs they buy, as long as they are fresh and have the desired size (mainly M and L). There are some preferences for shell colour, housing system and/or regional origin, but many shoppers would e.g. buy imported brown-shelled barn eggs (with a higher margin for the seller?) when they actually prefer cheaper white-shelled eggs from cage operations in the region. To determine real consumer preferences would require a designed experiment, where the same margin per m² shelf area is added to eggs of different production cost (depending on production system).

It will be easy to convince egg producers that “Kleingruppenhaltung” is the most promising alternative to conventional cages. From the limited experience with this system, there is little doubt that it is easy to operate; liveability, egg production per hen housed and feed cost per egg will be better, on average, than in floor systems.

Open questions are (1) whether the food industry is willing to list eggs with the code DE-3 to offer consumers a choice and (2) whether animal welfare organizations are prepared to accept “Kleingruppenhaltung” as a step in the right direction and perhaps better than importing eggs from countries with lower animal welfare standards.

While equipment companies are busy installing the systems currently available, we expect a continued demand for further developments of all systems, for which the WPSA can contribute valuable input from the analysis of field records and new international literature. The German government is currently planning to establish mandatory technical testing and monitoring (TÜV) for all poultry and animal housing systems. Such a system could also benefit from cooperation with experts of the WPSA, especially members of Working Group 9 (Poultry Welfare and Management).

Deutsche Gesellschaft für Geflügelwissenschaft e.V.: www.wpsa.de.

Flock, D.K. (2009):

Kleingruppenhaltung von Legehennen: Nur noch eine Frage der Aufklärung?

DGS Magazin 6/2009, 22-28.