What is the correct pre-incubation time and condition?

We must consider some real important points: On the egg storage, whether they were SPIDED or not as well as the temperature set point during storage are the main drivers for a good pre-warming program. An extra challenge is the air velocity through the eggs during the process of heating them up.

What is the correct pre-incubation time and condition?

We must consider some real important points: On the egg storage, whether They were SPIDES (“Short Period Incubation During Storage”) or not, the temperature set point during storage are the main drivers for a good pre-warming program An extra challenge is the air velocity trough the eggs during the process of heating them up.

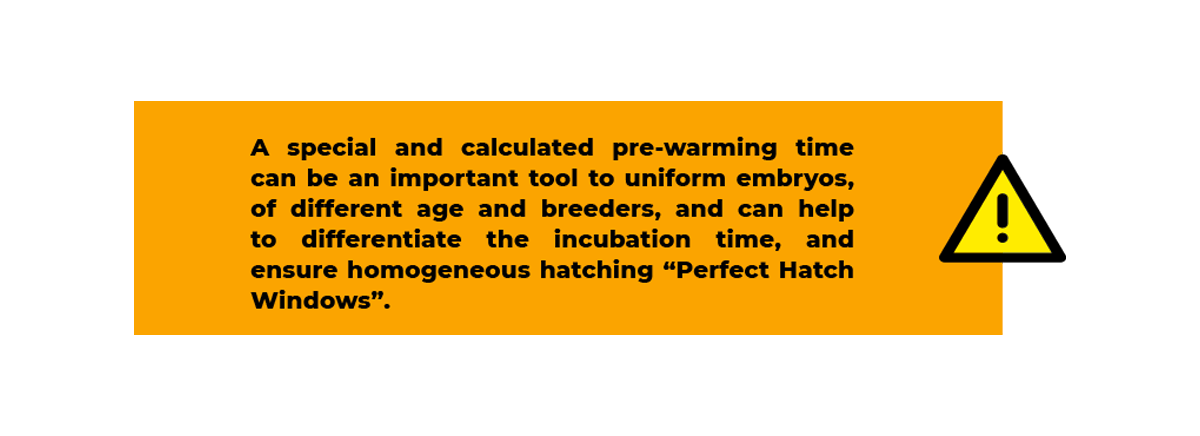

When embryos start off uniformly in the beginning, it is very likely they will later show a shortened hatch window, which delivers a better hydration level of the chicks as well more weight uniformity.

Pre-warming not only provides chicks with uniform development speed, but also, it is the most important tool to prevent condensation, especially in multistage systems when eggs are loaded with other batches of eggs in different stage of development.

Pre-warming not only provides chicks with uniform development speed, but also, it is the most important tool to prevent condensation, especially in multistage systems when eggs are loaded with other batches of eggs in different stage of development.

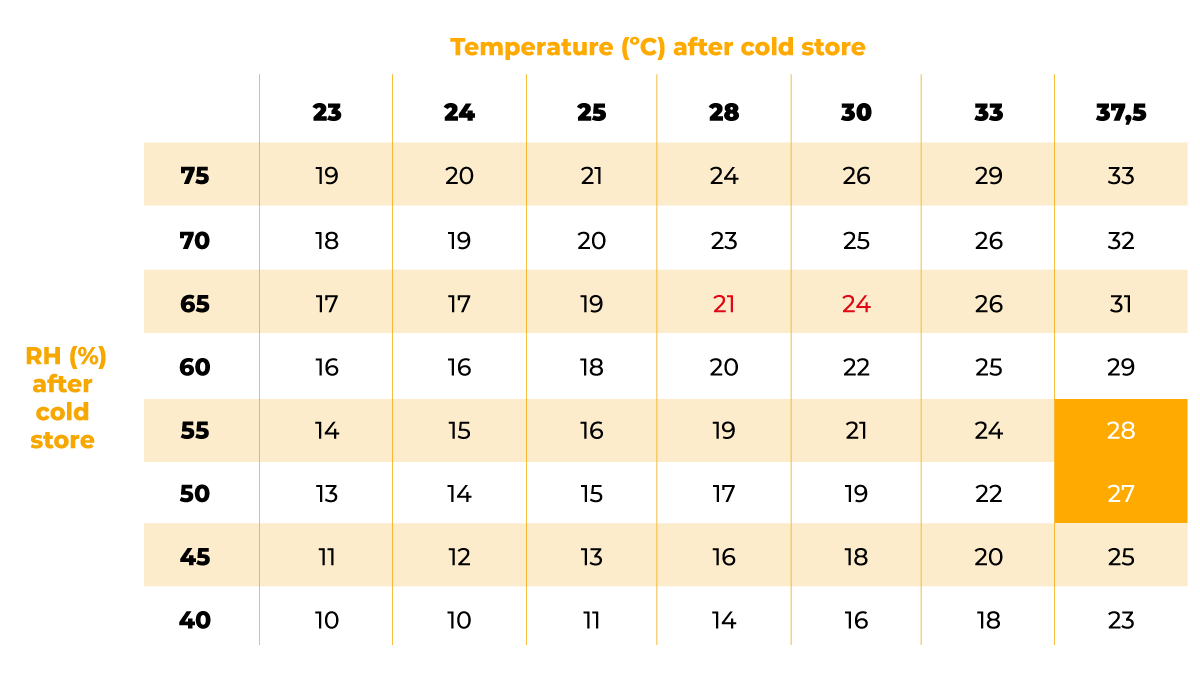

As we stated in the beginning of this article, condensation may occur at any time when we move eggs from a cold to a warmer environment. Therefore, condensation can take place also when we load pre-warmed eggs into the setters! To better understand the importance of pre-warming the eggs on condensation, we left the orange shaded cells on the right side of the table on purpose, showing 27ºC and 28ºC.

If we connect the temperature on the header of the table (37,5ºC) to the RH on the left side (50-55%) we will have pretty much what most multistage hatcheries have as profile for setters. It means that, to avoid condensation, eggs must be loaded into multi-stage machines at a minimum of 27ºC. Thus, pre-warming for this kind of machines should be made at a minimum of 27ºC.

If we connect the temperature on the header of the table (37,5ºC) to the RH on the left side (50-55%) we will have pretty much what most multistage hatcheries have as profile for setters. It means that, to avoid condensation, eggs must be loaded into multi-stage machines at a minimum of 27ºC. Thus, pre-warming for this kind of machines should be made at a minimum of 27ºC.

Can’t it be done at 25ºC? Yes, it can, but slight condensation will take place, even considering ventilation of the machine. When eggs condensate in the machine, not only contamination is a drawback, but evaporative cooling of wet egg surface is also of major concern since it will cool the eggs, causing a heterogeneous start of the process, damaging the hatch window 20-21 days later.

In case the pre-warming room has a high relative humidity enough to make the eggs to reach dew point and sweat, a dehumidifier installed in the room can help substantially. It removes the excess of water, making it virtually impossible to reach dew point. The good news is that a dehumidifier for a pre-warming room is a simple and cheap equipment.

For single stage system, we must follow the same rules on the table above. However, as the machines are empty, the pre-warm temperature can be much lower, usually the same as the setter corridor, around 24-26ºC with 50% RH.

In that case it is much less likely that eggs will condensate and, because of that, pre-warming can be carried out at a lower temperature, as per manager’s decision.

In that case it is much less likely that eggs will condensate and, because of that, pre-warming can be carried out at a lower temperature, as per manager’s decision.

When incubation program starts, temperature will raise gradually, which also avoids condensation.

When incubation program starts, temperature will raise gradually, which also avoids condensation.

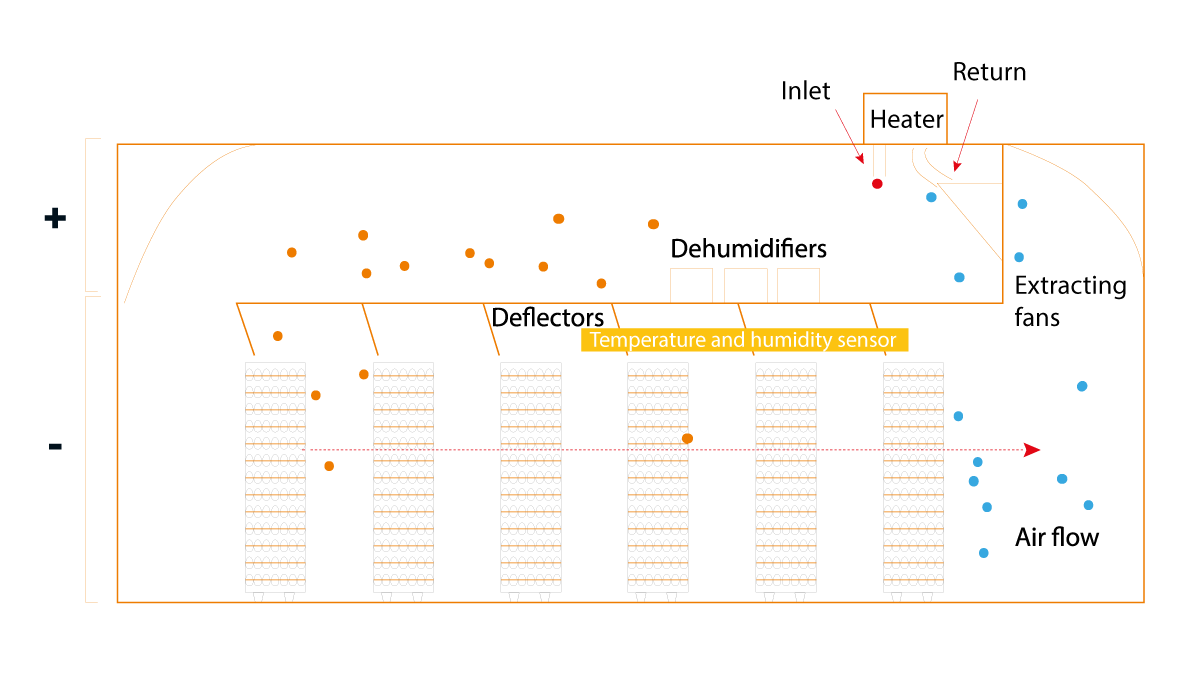

Image 1. A dehumidifier installed in a pre-warming room, with its reservoir being filled with water previously present in the air as vapor. By collecting this water, Relative Humidity in the environment drops to a level where dew point will never be reached when eggs are brought in.

Once we understood how important it is to prevent condensation, now it is time to understand why it is important to heat up the eggs as high as possible, especially in multistage systems.

Once we understood how important it is to prevent condensation, now it is time to understand why it is important to heat up the eggs as high as possible, especially in multistage systems. Once we understood how important it is to prevent condensation, now it is time to understand why it is important to heat up the eggs as high as possible, especially in multistage systems.

Once we understood how important it is to prevent condensation, now it is time to understand why it is important to heat up the eggs as high as possible, especially in multistage systems.

After the eggs are warmed, they can be loaded together with up to other 5 batches previously set in the same machine.

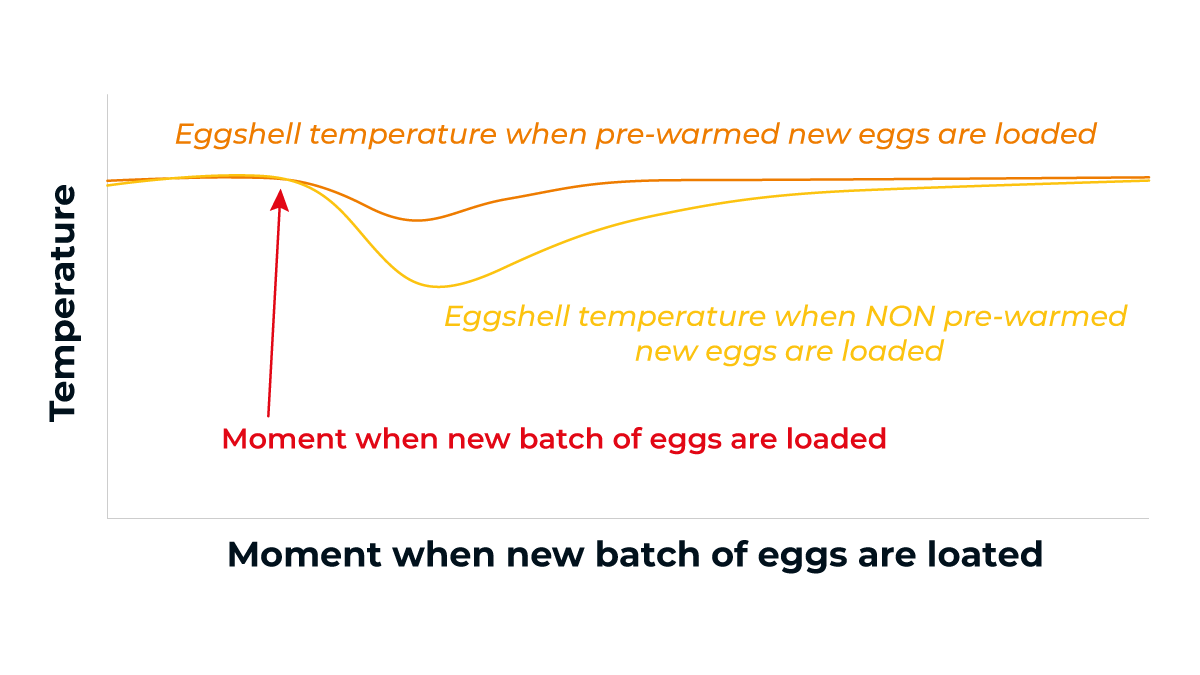

If eggs are loaded in a multistage machine without any pre-warming procedure, their cold mass will negatively influence the already set eggs, making their temperature do go down for a long time (not only machine’s temperature goes down).

Until the machine can overcome it by constant activation of heaters and dampers closure. Even when we prewarm them, there is a negative effect.

The warmer the eggs are loaded, the less harm they’ll cause to the existing eggs in the machines.

After the eggs are warmed, they can be loaded together with up to other 5 batches previously set in the same machine.

If eggs are loaded in a multistage machine without any pre-warming procedure, their cold mass will negatively influence the already set eggs, making their temperature do go down for a long time (not only machine’s temperature goes down).

Until the machine can overcome it by constant activation of heaters and dampers closure. Even when we prewarm them, there is a negative effect.

The warmer the eggs are loaded, the less harm they’ll cause to the existing eggs in the machines.

The graph above shows the temperature fluctuation undergone by existing eggs inside a multistage machine when a new batch of eggs is loaded with (purple line) or without pre-warming (yellow line).

In order to warm a big mass of eggs, we need not only a good heat source, but also means to ventilate the air uniformly so eggs can be heated homogeneously.

The best way to ventilate a large batch of eggs is by means of uniform airflow through each tray and this can be achieved by either using an empty machine or by having a dedicated well designed pre-warm room.

The pre-warm room can be a simulation of a tunnel ventilated chicken house, with air recirculation, since at this age, embryos need no fresh air at all.

The best way to ventilate a large batch of eggs is by means of uniform airflow through each tray and this can be achieved by either using an empty machine or by having a dedicated well designed pre-warm room.

The pre-warm room can be a simulation of a tunnel ventilated chicken house, with air recirculation, since at this age, embryos need no fresh air at all.

Picture 1. Sketch of a pre-warming room with a tunnel ventilation design. This will promote uniform airflow over the eggs, allowing a homogenous temperature increase.

Image 2. Actual pre-warming room for 300.000 eggs at once, showing the deflectors and trolley disposal.

Once the room is known, then it is a matter of calculation on how many extractors need to be installed to provide eggs with desired air speed. The use of deflectors on corners and eventually in some other strategic positions prevent air from seeking the way of least resistance.

Regardless of doing it on a sophisticated dedicated room, inside an empty machine or even in the setter hallway, we must make sure to provide eggs with uniform airflow and right temperature and humidity, for a correct start of development.

Please, feel free to contact LOHMANN BREEDERS Global Technical Service in case you need any help with this important step of the incubation process.

Please, feel free to contact LOHMANN BREEDERS Global Technical Service in case you need any help with this important step of the incubation process.

Once the room is known, then it is a matter of calculation on how many extractors need to be installed to provide eggs with desired air speed. The use of deflectors on corners and eventually in some other strategic positions prevent air from seeking the way of least resistance.

Regardless of doing it on a sophisticated dedicated room, inside an empty machine or even in the setter hallway, we must make sure to provide eggs with uniform airflow and right temperature and humidity, for a correct start of development.

Please, feel free to contact LOHMANN BREEDERS Global Technical Service in case you need any help with this important step of the incubation process.

Please, feel free to contact LOHMANN BREEDERS Global Technical Service in case you need any help with this important step of the incubation process.

Disclaimer

This TOOLBOX article remains the property of LOHMANN BREEDERS.

You may not copy or distribute any portions of the article without the prior written consent of LOHMANN BREEDERS.

For more information and further toolbox articles, please visit our website www.lohmann-breeders.com or contact us directly:

LOHMANN BREEDERS GMBH

Am Seedeich 9 – 11 27472 Cuxhaven / Germany

E-mail: info@lohmann-breeders.com

Incubation

Incubation