A control point for a perfect incubation

During transfer time at hatcheries, having a perfect egg weight loss is a good indication that we can expect good hatch results, but obtaining this target loss isn’t as simple as it sounds. This is due to an array of variables present at the hatchery that impact egg weight loss considerably, such as:

- General location

- External condition

- Flock age

- Egg shell quality

- Egg uniformity

- Egg age

- Storage conditions

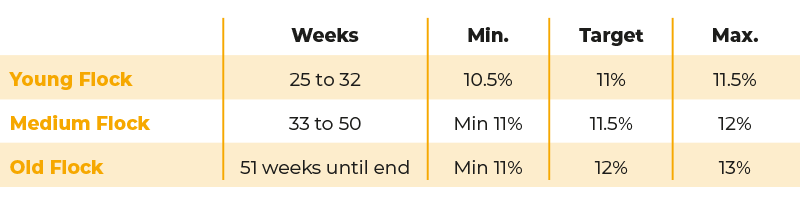

The following table shows the trend of egg weight loss during storage.

With every SPIDES, egg weight loss increases on average by 0.5%.

In this article, we analyze a Multi-Stage incubator philosophy, that heavily relies on “constant egg weight loss”, driven by the humidity and CO2 set points, that the hatchery management can’t afford to underestimate.

Therefore, they have a dedicated setter that’s only used (as much as possible) for eggs of similar parameters like flock age or same fertility.

This approach can help a lot to obtain the right egg weight loss value, with a simple change of the humidity set-point.

The number of pores can range from 7.000 to 17.000, and can either exacerbate or help conserve egg weight loss.

The number of pores is influenced by:

- Flock age

- Eggs shell quality

- Nutrition

- Health conditions

- Altitude of the farm relative to the sea level

“Constant” or “Diversified” egg weight loss

This is completely different when compared to a Single-Stage philosophy, where you can work with a “constant” or “diversified” egg weight loss.

The setters have a humidification system and works with respect to a fixed value of humidity set point, CO2 set point and damper opening value.

In Hypercapnia (elevated CO2) incubation, the setter is tightly sealed and uses the moisture content of the eggs to maintain the humidity value.

For this reason, humidity is high during the first phase of incubation (approximately 1 week), and decreases after the opening of the damper.

The latter is controlled by the presence of CO2 in the early embryos, that have to help the life and dimension of embryo.

For this reason, it’s very important to know and test the real efficiency of our incubation program (profiles), and modify them based on the needs of our eggs.

Damper opening time, humidity set point and air-flow velocity are all settings that can impact the% of egg weight loss.

Both systems mentioned have their pros and cons, however it is up to our knowledge and common sense to get the desirable results of egg weight loss.

Accurate data recording and operating based on those data is the basis for success.

Therefore, in all LOHMANN hatcheries, eggs are weighed upon arrival so we can have a perfect control start point, and then again at storage before they receive their 444 hours of incubation, at then one last time during transfer at 18.5 days.

The percentage of moisture required to transport nutritive elements and allow proper yolk sac assimilation will be met, thus ensuring the survivability of the embryos.

Incubation

Incubation