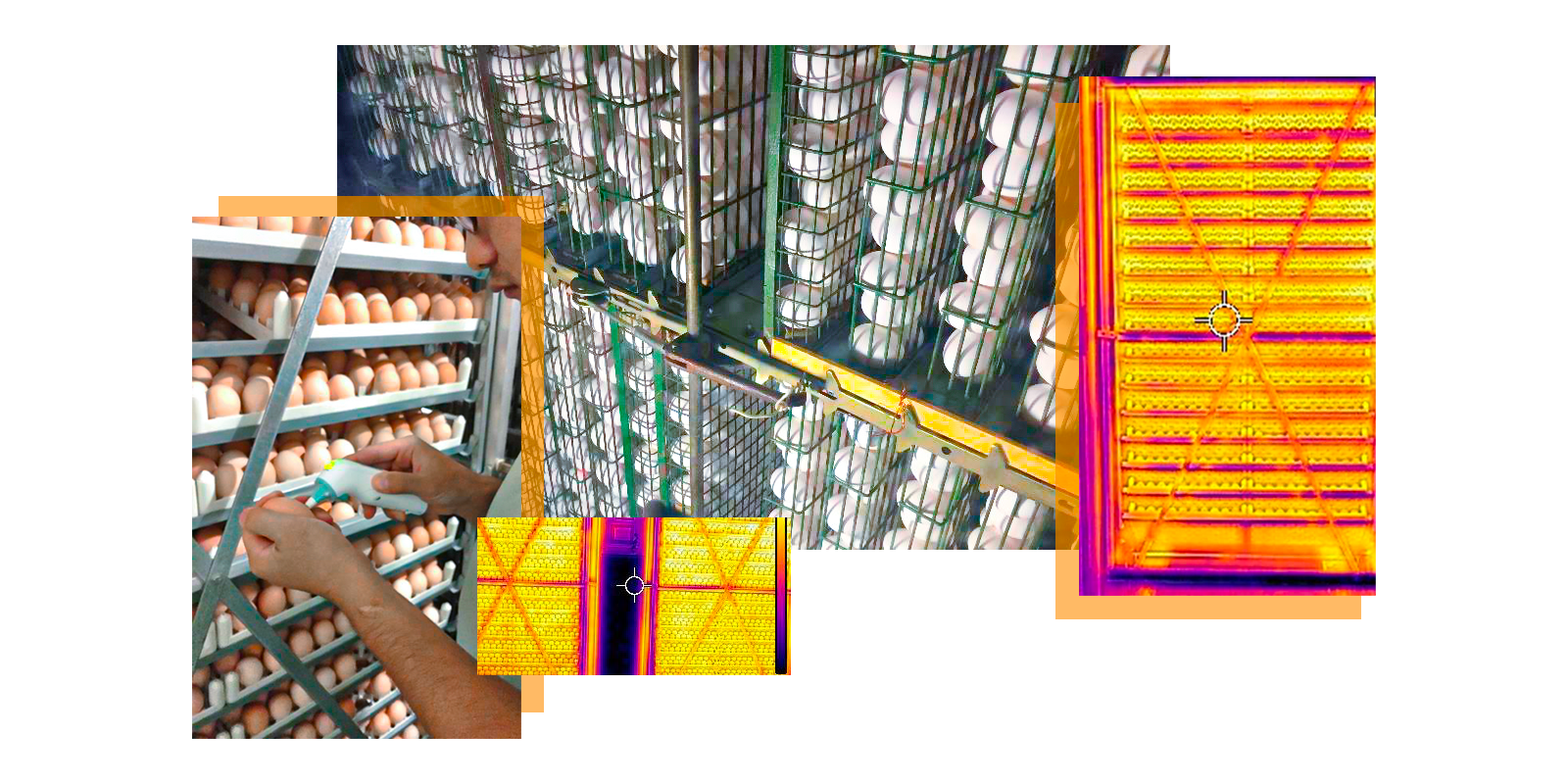

One of the most significant hatchery changes around the world during the last years is the migration from multi-stage to single-stage systems. Although the majority of birds still hatch on multi-stage systems.

Since a few years most of the new projects are being built with the new single stage concepts, indicating the poultry world is now undergoing this technological shift.

What are the main differences between these two systems?

Before explaining their differences, one must be aware of the concept of each system.

Management

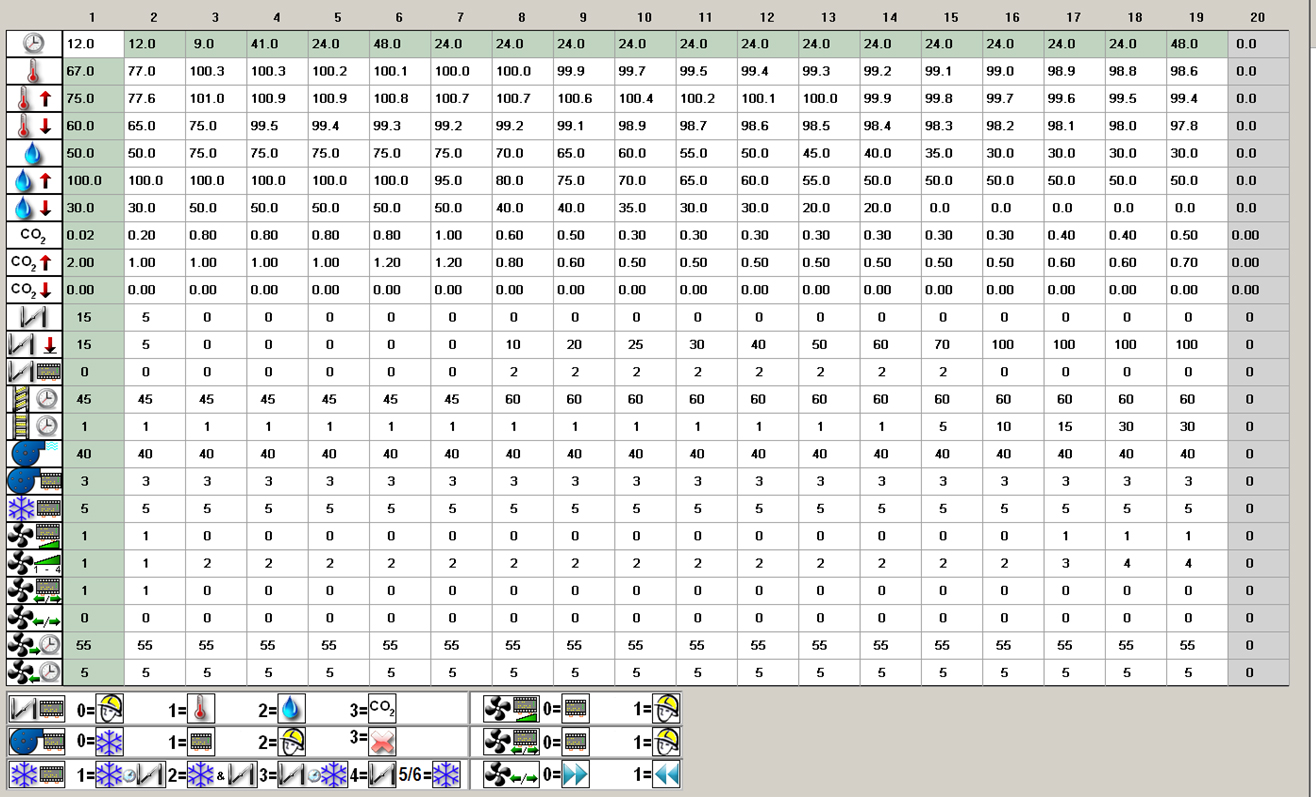

Regarding management, the multi-stage system often works with fixed parameters such as temperature, relative humidity, and CO2 levels.

Hatchery managers fine tune what gives the best hatchability of saleable chicks and stick to it regardless of:

- The flock origin

- Breed

- Age

- Egg age

When managed in a good way, some machines can be dedicated to specific batches of eggs and have their specific parameters fixed for the entire duration of the incubation period.

In this eventuality dedicate some specific machine in consideration of age, with specific setting, for Young/Prime/Old can done advantage in the best control of the egg weight loss.

The hygiene aspects of multi-stage systems are still one of the strongest handicaps, since the machines are almost impossible to be cleaned and disinfected regularly as on a usual fully utilized hatchery as these machines are never empty or even turned off.

The other hindrance is the impossibility to work with dynamic control of incubation parameters such as temperature, humidity and CO2.

There is where single-stage machines can outperform the old multi-stage concept.

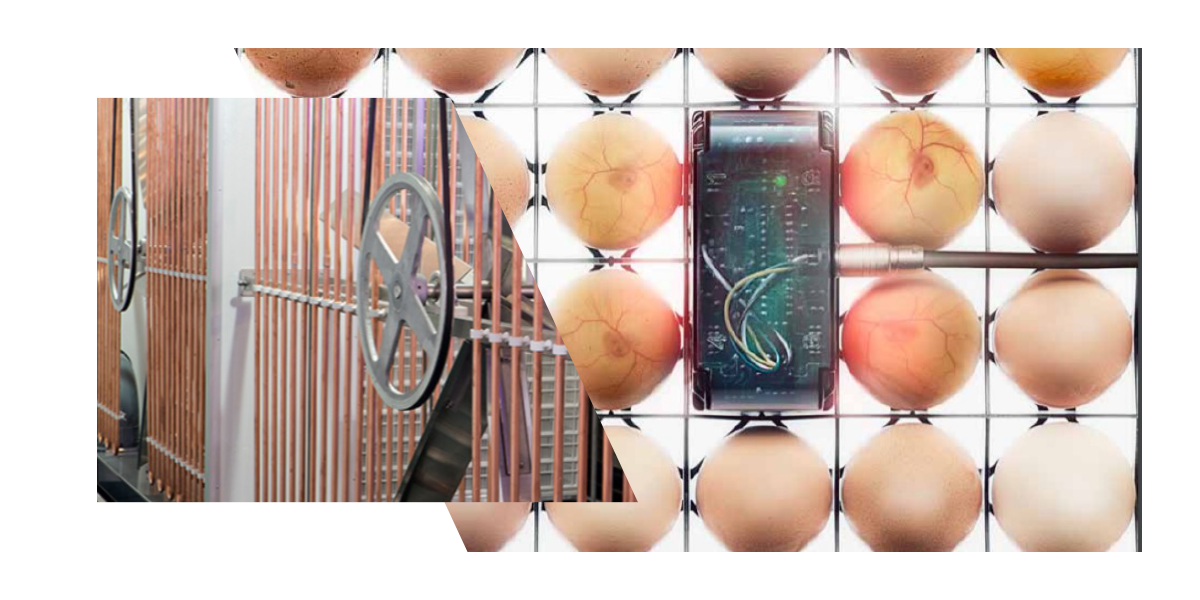

Single stage machines

Single stage machines can be emptied, cleaned, and disinfected after every cycle of 18-19 days.

They can even be turned off for around 2 days, promoting some energy savings as well. However, this is not the only benefit of using this system.

Current research and development carried out by universities, incubator and breeding companies have demonstrated that embryo requirements change during incubation, according to the stage of development.

It means that temperature, humidity and CO2, for example, have variable optimum levels during the entire life of the embryo.

Meeting these requirements can be done only by using single stage machines.

The result of a tailor-made incubation profile can be translated into:

- Better saleable chick hatchability

- Narrow hatch window (time from first to last chicks to hatch in a machine)

- Consequently better first week performance in terms of body weight gain, uniformity and livability

Several companies can supply both incubation systems, but it is well agreed that investments are predominantly aimed to single stage, as a reflex of the best results achieved.

Incubator manufacturers work hard in making a more stable environment inside the cabinets and on predicting what the embryo needs are now and will be in near future.

- More durable parts

- More efficient motors

- New technologies that allow recovery of the heat produced by the embryos to be used for instance on ventilation system, dropping energy consumption by the entire building

Nowadays it is no longer unusual to have single stage hatcheries with less energy consumption than those having multistage machines.

Embryo physiological behavior

New machines can react to the embryo physiological behavior by cooling or heating to keep eggshell on proper temperature, opening/closing air valves in order to allow more oxygen in and expel CO2 and water produced by embryo metabolism on the right amount at the right time.

Not only these systems are capable of doing such controls, but they are more accurate in the readings of every parameter involved on the incubation process, providing hatchery managers with more dependable process and equipment.

Our team of specialists can assist you at any time when deciding which system to buy or even when you need advices for your running hatchery.

Count on us!

Incubation

Incubation