In today’s poultry operations, hygiene is an essential part

of the management system. A good and reliable biosecurity

and hygiene concept should be established to prevent outbreaks of diseases and to ensure good performance conditions. Only flocks which perform well can secure a reliable

source of income for poultry companies. Keeping medical

treatment to an absolute minimum should be one of the

most significant goals during production, both from an animal welfare and an economical point of view.

Disasters like the outbreak of epidemics are always indicators of inadequate biosecurity. There are different measures

to restrict pathogens from getting into contact with the birds

on the farm. The types of measures which are implemented

depend on the specific situation on each farm. Basic hygienic

rules, however, like the washing of hands and changing of

shoes before entering a barn, should always be performed.

They help to keep the hygienic status of a flock on a high

level.

What are we fighting?

The biggest problem with biosecurity rules is that untrained people may think that these were only established to make their daily work even harder and more uncomfortable. Therefore, to make the whole system successful, it is of most importance to provide training on biosecurity practice to the staff involved.

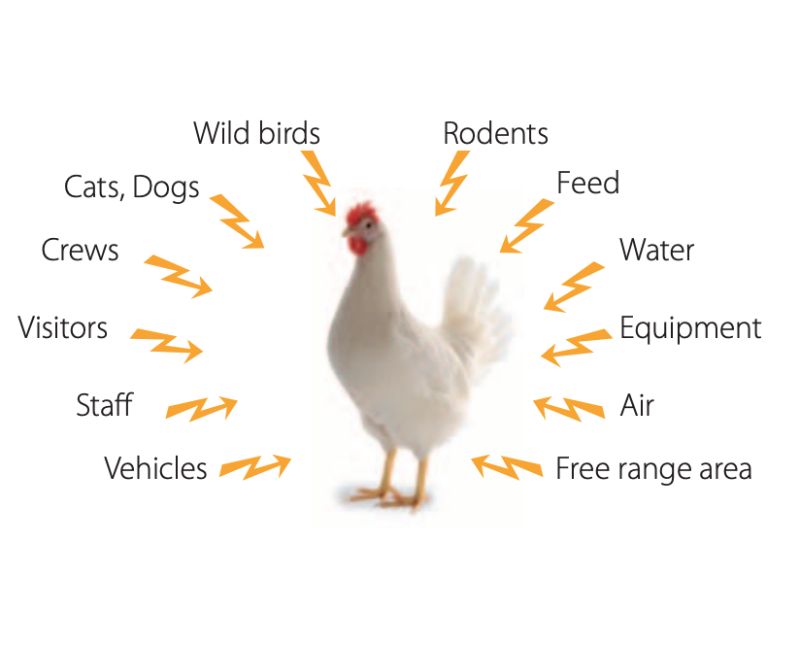

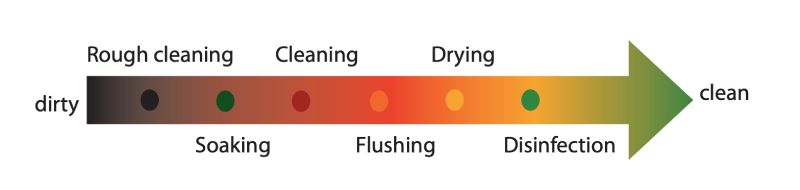

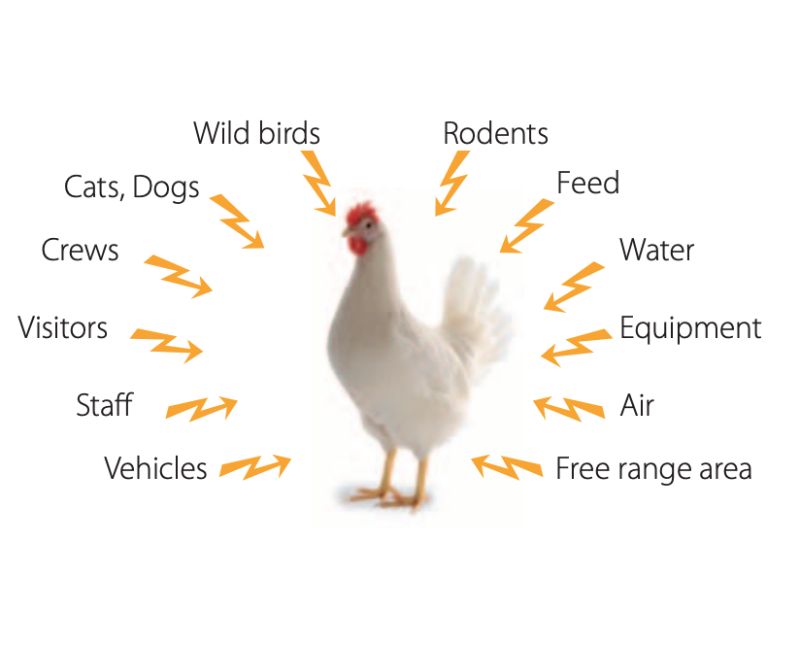

It is crucial to explain that disease-causing organisms (whether viruses, bacteria, or parasites), are often invisible to the naked eye and to make people aware of how these pathogens are usually spread (see picture 1).

The most recent ways of pathogen transmission are as follows:

• Faecal to oral: Pathogens are excreted in the faeces and are consumed by susceptible chickens.

• Aerosol: Pathogens are transmitted in microscopic droplets of moisture/dust and are inhaled by the hens.

• Mechanical Vectors: Pathogens travel on people, insects and can therefore be brought into physical contact with layers.

• Biological Vectors: Carry pathogens in their body and transmit the disease either by being consumed, by biting or by spread of infectious particles (e.g. faeces).

Picture 1: Some ways of how pathogens can reach the layers

Good Biosecurity Practice – Farm Layout

In terms of the possible methods of transmission of pathogens, one of the most important measures in Biosecurity is to have as much distance to other poultry operations as possible. Therefore, build the farm in a minimum distance of 1 km to other farms and choose an area with a low poultry density and if possible, no presence of wild birds or water fowls.

The entire farm has to be fenced and information signboards should be fitted in order to make everybody aware of a critical area in which biosecurity rules have to be strictly followed. Buildings have to be kept free of vegetation. Long grass, trees and bushes will attract rodents and wild birds. A good possibility would be to build a 2-meter strip of a pebbled pathway around the perimeter of each house (see picture 2).

Picture 2: well-maintained surrounding of a poultry house

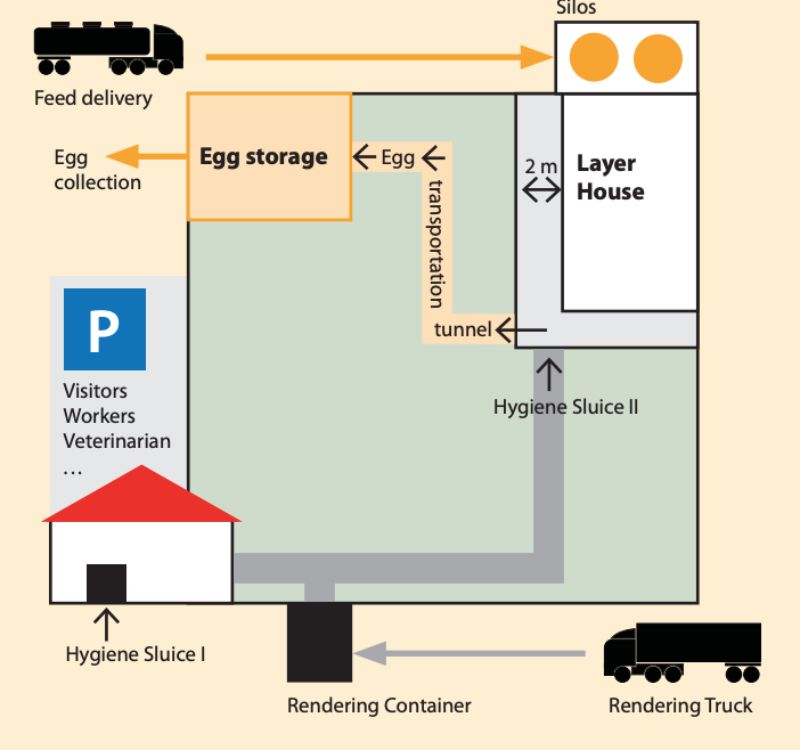

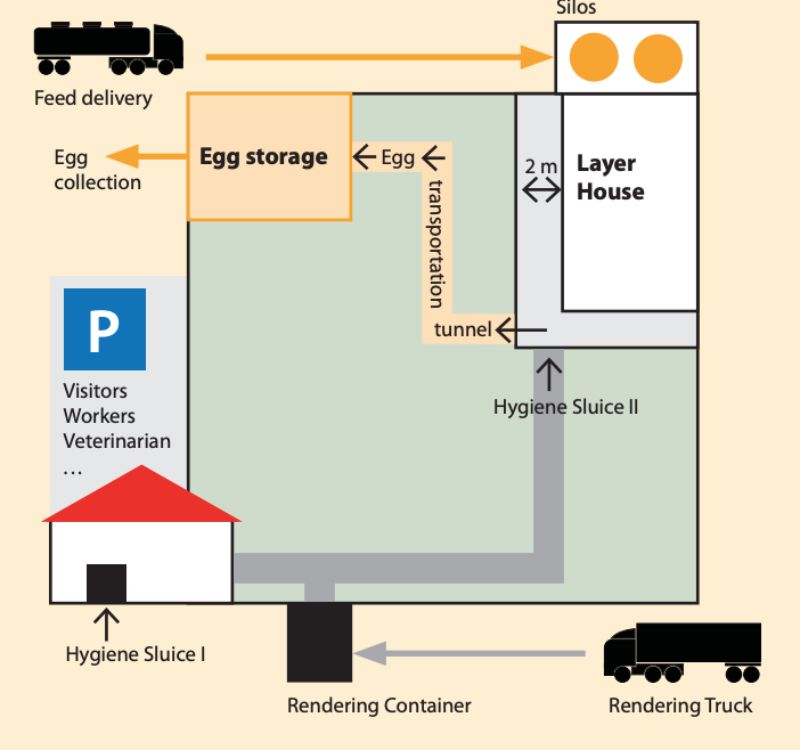

Generally, the farm should be divided into clean and dirty areas. “Dirty” activities include the handling of manure, removal of carcasses and pests as well as contact with rendering containers or rendering trucks. “Clean” activities comprise of egg, chick and feed handling, movements of birds, and numerous daily activities which involves direct contact with the birds. It is preferable that equipment and personnel not be shared between clean and dirty activities! If this is not possible, then clean activities should first be completed before dirty activities are carried out. Upon completion of their tasks in these areas, the personnel should be dismissed for the day.

Cars should not have access to the premises. If the frequency of vehicles cannot be avoided (e.g. feed delivery trucks), then these must be cleaned and disinfected before allowing them to enter the farm grounds. It should be a matter of course that these trucks have not been to other farms before, and if this would be otherwise, then they should always start with the youngest to the oldest birds that are present on the different farms. Picture 3 shows how vehicles can be kept out of premises. This, however, is not always possible.

Picture 3 also shows how workers and visitors should enter the farm. Reduce vehicle and visitor movements at your respective sites. Be aware that the most common visitors like veterinarians and consultants are the most dangerous ones because they would have most likely been to other farms before. Prepare a visitors logbook to have a record of traceability in the event of a disease outbreak.

Picture 3: Design of a farm in observance of biosecurity rules

Picture 3: Design of a farm in observance of biosecurity rules

The procedure for every visitor and worker when entering farm level is via a shower in facility (see picture 4). The first step would be for them to leave their own clothes, accessories and jewelry in a locker. The second step is to take a shower and to put on clothing and shoes as provided by the farm.

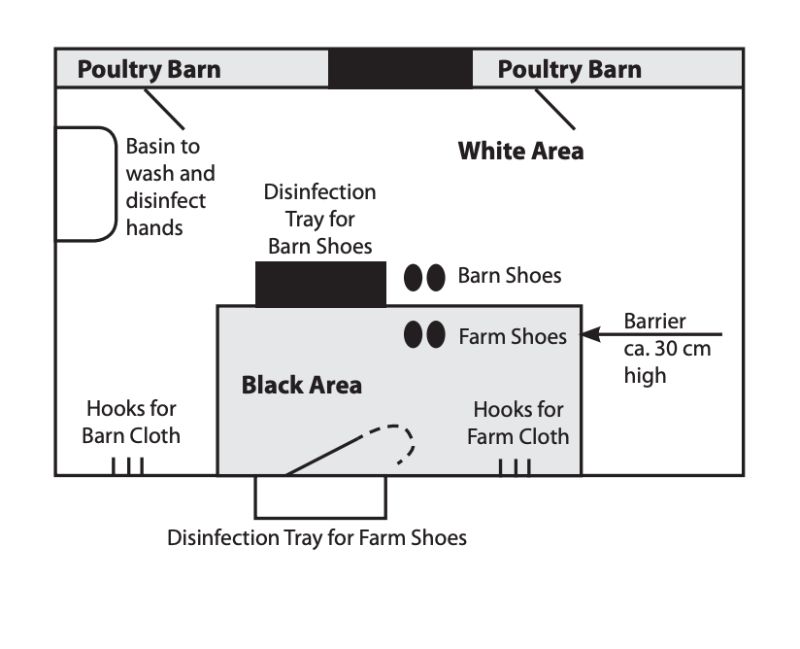

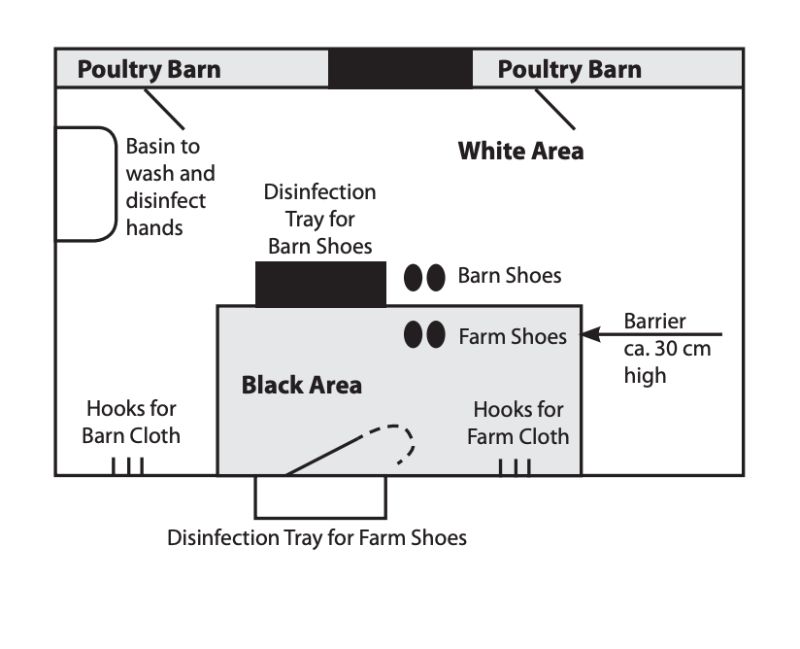

Biosecurity measures should not just stop after showering. It should also be implemented at farm level throughout the lifespan of the flocks as well as during the cleaning and disinfection time to follow. Every poultry house should have an own hygiene station which every person has to pass through before accessing the birds. These hygienic stations can be kept very simple but in any case, shoes should always be changed, a barn-owned overall should be worn and hands should be washed. Picture 5 displays a simple example of how an effective hygienic station can be realized on barn level.

Always try to work with very simple solutions which makes it easy for every person to exercise biosecurity rules in their daily routines. This is the most effective guarantee to make the whole biosecurity program successful and effective on your farm. Picture 6 shows an example on how easy it can be to change shoes in the anteroom of the poultry house.

Keep in mind that the solution of the disinfection footbath has to be changed on a daily basis. Otherwise, they are more harmful than helpful. A substitute of the disinfection bath is a pad with chlorine powder that only needs to be changed every fortnight (see picture 7). This has the advantage, i.e. that the powder is not slippery and leaves a much cleaner residue.

Picture 4: Example of a one-way shower

Picture 5: Plan for a simple sanitation area in a poultry facility

Picture 6: Simple and easy way of shoe changing and disinfection on barn level

Picture 7: Chlorine Foot Pan Powder

Good Biosecurity Practice – Bird Management

To reduce the pressure of infectious agents on your farm, it is advisable to avoid multiaged farms in which diseases and vermin can easily survive and spread to the different age groups. Therefore All-in All-out management is the best principle from a biosecurity point of view! If that is not possible, handle every age group as a separate unit. Avoid crossing equipment, feed, eggs, staff, etc. Traffic should always flow from the youngest to the oldest and from healthy to sick birds.

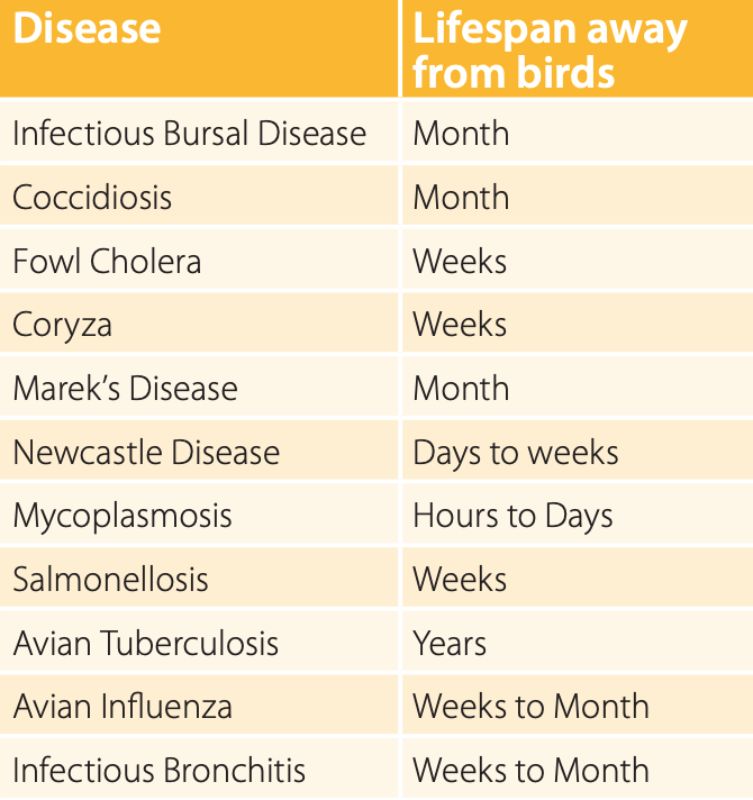

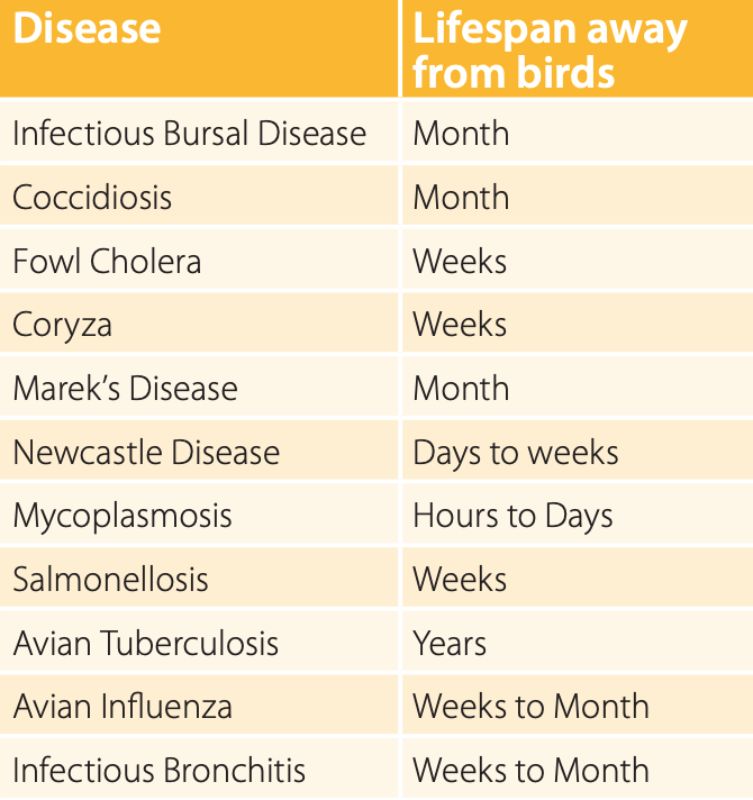

An effective reduction of pathogens can also only be powerful by choosing enough downtime between flocks. The longer the service period, the better it is for the hygienic status of the farms. As table 1 shows, some pathogens are able to persist for a very long time in the environment even if the birds are not present. Therefore, choose the turnaround period based on the latest diseases you have had on your farm.

Table 1: Longevity of some disease-causing organisms (BELL and WEAVER; 2002)

Cleaning and Disinfection

Cleaning and disinfection are measures to reduce the amount of disease-causing organisms to a minimum. Therefore, they are important tools of a biosecurity program.

It is impossible to achieve absolute sterility on farm level but the goal should always be to reduce the bacterial load as far as possible.

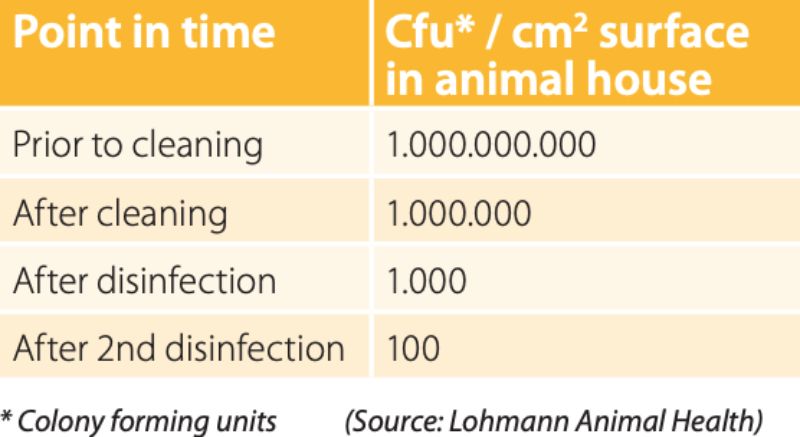

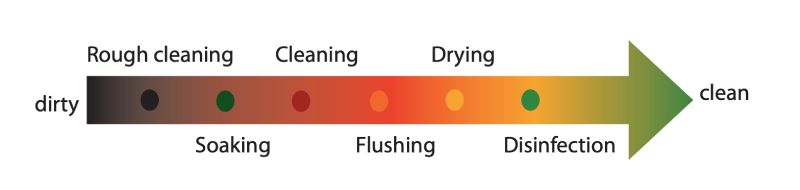

In order to achieve the best possible cleaning result, the whole procedure has to be performed correctly. Therefore, it is helpful to divide the cleaning and disinfection measures into 6 main steps, which lead – i.e. when strictly followed – to very good results in terms of the hygienic status of the farm (picture 8).

Step 1 – Rough cleaning: Treat the house while it is still warm with insecticides to eliminate flies, beetles, etc. Remove litter and dirt. Transfer these to somewhere as far away as possible.

Step 2 – Soaking: Soak the facility for several hours. Use enough liquid to soak. Tenside solutions help to combat stubborn dirt. Soaking when properly done can help to reduce the time of real cleaning.

Step 3 – Cleaning: Use a high pressure cleaner to carry out the cleaning of the shed. Do this either with hot or cold water, depending on the detergent you are using during cleaning.

Step 4 – Flushing: Rinse the facility with enough clear water after cleaning.

Step 5 – Drying: Let the facility dry properly. This is important as puddles of any kind will dilute the disinfectant to be used after drying.

Step 6 – Disinfection: During application of the disinfectant, the house has to be sealed and the ventilation has to be switched off. Disinfection will reduce the amount of infectious agents to a minimum. Therefore, use a minimum of 0.4 l /m2 of floor space. Disinfect from the rear to the front of the poultry house and from the ceiling to the floor. Do not work with a water pressure of more than 10 to 12 bar.

Choose disinfectants with a broad range of efficacy. They should be effective against bacteria as well as against fungus. If you had extraordinary problems with the last flock, consult your veterinarian for advice on the right disinfectant to apply.

Picture 8: 6 steps of good cleaning and disinfection procedures (DLG, 2010)

Keep in mind: Disinfection without proper cleaning has no effectiveness. Increasing the concentration of a disinfectant is never a substitute for thorough cleaning. During the disinfectant procedure some problems can occur. These particularly include the following:

1. Protein error: Occurs if in an unclean environment, the disinfectant reacts with faeces and other dirt before it can actually react with bacteria or other infectious agents

2. Soap mistake: Disinfectants can be inactivated if they react with residues of cleaning agents. Therefore, it is important to rinse the facility with clear water after cleaning and to dry it thoroughly.

3. Temperature mistake: Some substances like Aldehydes do not work with temperatures which are below 10°C. The activity of many disinfectants improves significantly as the temperatures rise.

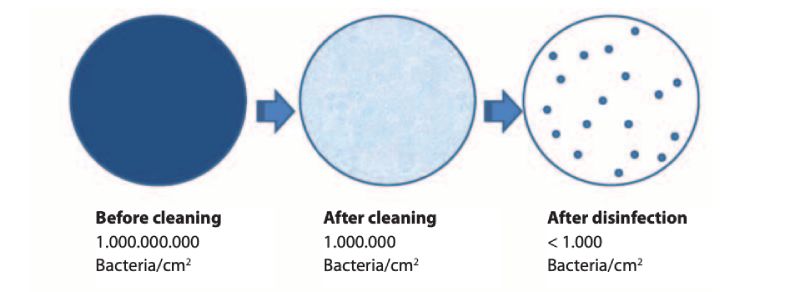

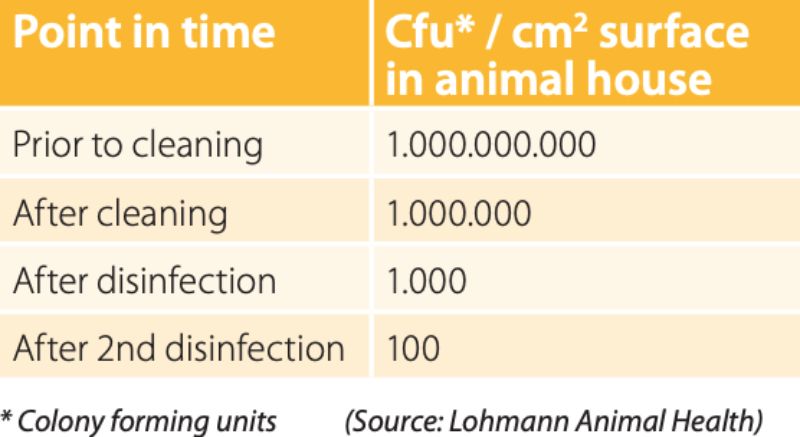

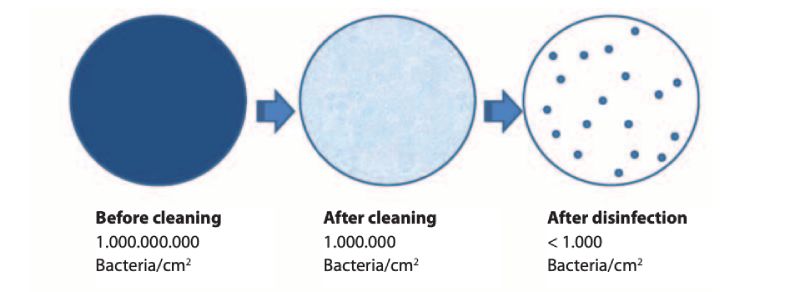

To make sure that the cleaning procedure was effective, the results should be tested either by your veterinarian or by your own quality department. The following figures shown in table 2 and picture 9 can be treated as guidelines where bacterial loads are concerned.

Table 2: Microbial contamination of surfaces before and after cleaning and disinfection (benchmark)

Picture 9: Bacterial load before and after cleaning and disinfection (DLG, 2010)

Water and Feed

Water and feed as well as their distribution systems are carriers for pathogens into the poultry facilities. These are often overlooked since farm and production managers focus their efforts on monitoring other management tools.

It is important to integrate water lines, silos and feeding chains into the biosecurity program so as to maximize cleanliness, edibility and potability of feed and water.

Clean and disinfect water lines regularly, especially before and after each treatment with vitamins, vaccination and medication. If this is not performed, a biofilm will build up which can harm the quality of your water. Pathogens like E.Coli, Salmonella can accumulate very easily in biofilms.

Ways to keep the water lines mechanically clean include the use of pulsed water or with special water lines where the water is constantly in motion and little particles and sediments cannot stick on the walls of the pipes. The other possibility to maintain the hygienic status of the water lines on a high level is to treat the water chemically.

Chlorination

• Eliminates bacteria and many viruses

• Most effective in warm water > 18 °C

• Can affect the potency of medication and vaccines

• Concentrations > 5% can harm metal equipment and gaskets

Chlorine dioxide

• No interactions known with medication

• Improves digestive health of the flock

Organic acids

• Reduce the pH value of the water

• Improve digestive health of the birds

• Single acid application can cause slime

formation and block pipelines and nipples. High dosages of single acids can damage water system and also be fatal to the birds

• Organic acids are also a tool to reduce bacterial load in feed

Caution: If the pH value of the water drops to a low level, this will have a negative impact on water intake and can have a negative effect on the equipment as well as vaccines and medication.

The water quality has to be checked on a regular basis. If the water is supplied by an own well, make sure that the samples of water are examined at least twice a year. Feed has to always be of best quality. Establishing a quality monitoring program helps to assure and to monitor nutrient content, microbial and mycotoxin contamination. One of the key factors is to store supplements hygienically to avoid contamination during storage.

Besides storage, clean feed can also be contaminated during transportation. Therefore, it is important to include trucks into the biosecurity regime. The feed supplier has to be certified and controlled. He should be able to perform heat treatment as a tool of sanitation, although very high temperatures might have an impact on the quality and may reduce the nutrient value of the feed. Retain a sample and bill of each delivery to have traceability in the event of a disease outbreak.

Rodent Control

Rodents are attracted to poultry facilities by feed, water and environmental conditions in the barn. They contaminate poultry facilities with faecal excretions and are major vectors and reservoirs of pathogens; especially Salmonella. Therefore, having an effective vermin control in place is a big advantage. Take expert advice and audit the success of the monitoring program regularly.

New Technical Guide Biosecurity & Hygiene

We are pleased to introduce our latest Technical Guide on “Hygiene and Biosecurity” where all the discussed topics have been compacted for you. The guide is available in English, German and Spanish. Please contact our marketing department: marketing@ltz.de to place your orders for the same.

Djanet Ould-Ali, Technical Service

Photos courtesy of (l-r): Ms. Hannah Dunn, Mr. Ian Dunn, Ms. Norrie Russell

It is probably not upper – most in your mind when you dye eggs for Easter that you are depending on an invisible structure called the cuticle being present.

The amount of change in colour you see depends on how much cuticle is present on the egg. Having colourful Easter eggs is good news, but more importantly the cuticle prevents bacteria entering the egg. This reduces the chance bacteria can reach the developing chick if the egg is fertile and keeps the eggs we eat safe.

With industry we are developing tools which are more practical, although less colourful, to measure the amount of cuticle on an egg. This will allow genetic selection to improve the cuticle and improve biosecurity for poultry.

Ian Dunn Ph.D

What are we fighting?

The biggest problem with biosecurity rules is that untrained people may think that these were only established to make their daily work even harder and more uncomfortable. Therefore, to make the whole system successful, it is of most importance to provide training on biosecurity practice to the staff involved.

It is crucial to explain that disease-causing organisms (whether viruses, bacteria, or parasites), are often invisible to the naked eye and to make people aware of how these pathogens are usually spread (see picture 1).

The most recent ways of pathogen transmission are as follows:

• Faecal to oral: Pathogens are excreted in the faeces and are consumed by susceptible chickens.

• Aerosol: Pathogens are transmitted in microscopic droplets of moisture/dust and are inhaled by the hens.

• Mechanical Vectors: Pathogens travel on people, insects and can therefore be brought into physical contact with layers.

• Biological Vectors: Carry pathogens in their body and transmit the disease either by being consumed, by biting or by spread of infectious particles (e.g. faeces).

Picture 1: Some ways of how pathogens can reach the layers

Good Biosecurity Practice – Farm Layout

In terms of the possible methods of transmission of pathogens, one of the most important measures in Biosecurity is to have as much distance to other poultry operations as possible. Therefore, build the farm in a minimum distance of 1 km to other farms and choose an area with a low poultry density and if possible, no presence of wild birds or water fowls.

The entire farm has to be fenced and information signboards should be fitted in order to make everybody aware of a critical area in which biosecurity rules have to be strictly followed. Buildings have to be kept free of vegetation. Long grass, trees and bushes will attract rodents and wild birds. A good possibility would be to build a 2-meter strip of a pebbled pathway around the perimeter of each house (see picture 2).

Picture 2: well-maintained surrounding of a poultry house

Generally, the farm should be divided into clean and dirty areas. “Dirty” activities include the handling of manure, removal of carcasses and pests as well as contact with rendering containers or rendering trucks. “Clean” activities comprise of egg, chick and feed handling, movements of birds, and numerous daily activities which involves direct contact with the birds. It is preferable that equipment and personnel not be shared between clean and dirty activities! If this is not possible, then clean activities should first be completed before dirty activities are carried out. Upon completion of their tasks in these areas, the personnel should be dismissed for the day.

Cars should not have access to the premises. If the frequency of vehicles cannot be avoided (e.g. feed delivery trucks), then these must be cleaned and disinfected before allowing them to enter the farm grounds. It should be a matter of course that these trucks have not been to other farms before, and if this would be otherwise, then they should always start with the youngest to the oldest birds that are present on the different farms. Picture 3 shows how vehicles can be kept out of premises. This, however, is not always possible.

Picture 3 also shows how workers and visitors should enter the farm. Reduce vehicle and visitor movements at your respective sites. Be aware that the most common visitors like veterinarians and consultants are the most dangerous ones because they would have most likely been to other farms before. Prepare a visitors logbook to have a record of traceability in the event of a disease outbreak.

Picture 3: Design of a farm in observance of biosecurity rules

Picture 3: Design of a farm in observance of biosecurity rules

The procedure for every visitor and worker when entering farm level is via a shower in facility (see picture 4). The first step would be for them to leave their own clothes, accessories and jewelry in a locker. The second step is to take a shower and to put on clothing and shoes as provided by the farm.

Biosecurity measures should not just stop after showering. It should also be implemented at farm level throughout the lifespan of the flocks as well as during the cleaning and disinfection time to follow. Every poultry house should have an own hygiene station which every person has to pass through before accessing the birds. These hygienic stations can be kept very simple but in any case, shoes should always be changed, a barn-owned overall should be worn and hands should be washed. Picture 5 displays a simple example of how an effective hygienic station can be realized on barn level.

Always try to work with very simple solutions which makes it easy for every person to exercise biosecurity rules in their daily routines. This is the most effective guarantee to make the whole biosecurity program successful and effective on your farm. Picture 6 shows an example on how easy it can be to change shoes in the anteroom of the poultry house.

Keep in mind that the solution of the disinfection footbath has to be changed on a daily basis. Otherwise, they are more harmful than helpful. A substitute of the disinfection bath is a pad with chlorine powder that only needs to be changed every fortnight (see picture 7). This has the advantage, i.e. that the powder is not slippery and leaves a much cleaner residue.

Picture 4: Example of a one-way shower

Picture 5: Plan for a simple sanitation area in a poultry facility

Picture 6: Simple and easy way of shoe changing and disinfection on barn level

Picture 7: Chlorine Foot Pan Powder

Good Biosecurity Practice – Bird Management

To reduce the pressure of infectious agents on your farm, it is advisable to avoid multiaged farms in which diseases and vermin can easily survive and spread to the different age groups. Therefore All-in All-out management is the best principle from a biosecurity point of view! If that is not possible, handle every age group as a separate unit. Avoid crossing equipment, feed, eggs, staff, etc. Traffic should always flow from the youngest to the oldest and from healthy to sick birds.

An effective reduction of pathogens can also only be powerful by choosing enough downtime between flocks. The longer the service period, the better it is for the hygienic status of the farms. As table 1 shows, some pathogens are able to persist for a very long time in the environment even if the birds are not present. Therefore, choose the turnaround period based on the latest diseases you have had on your farm.

Table 1: Longevity of some disease-causing organisms (BELL and WEAVER; 2002)

Cleaning and Disinfection

Cleaning and disinfection are measures to reduce the amount of disease-causing organisms to a minimum. Therefore, they are important tools of a biosecurity program.

It is impossible to achieve absolute sterility on farm level but the goal should always be to reduce the bacterial load as far as possible.

In order to achieve the best possible cleaning result, the whole procedure has to be performed correctly. Therefore, it is helpful to divide the cleaning and disinfection measures into 6 main steps, which lead – i.e. when strictly followed – to very good results in terms of the hygienic status of the farm (picture 8).

Step 1 – Rough cleaning: Treat the house while it is still warm with insecticides to eliminate flies, beetles, etc. Remove litter and dirt. Transfer these to somewhere as far away as possible.

Step 2 – Soaking: Soak the facility for several hours. Use enough liquid to soak. Tenside solutions help to combat stubborn dirt. Soaking when properly done can help to reduce the time of real cleaning.

Step 3 – Cleaning: Use a high pressure cleaner to carry out the cleaning of the shed. Do this either with hot or cold water, depending on the detergent you are using during cleaning.

Step 4 – Flushing: Rinse the facility with enough clear water after cleaning.

Step 5 – Drying: Let the facility dry properly. This is important as puddles of any kind will dilute the disinfectant to be used after drying.

Step 6 – Disinfection: During application of the disinfectant, the house has to be sealed and the ventilation has to be switched off. Disinfection will reduce the amount of infectious agents to a minimum. Therefore, use a minimum of 0.4 l /m2 of floor space. Disinfect from the rear to the front of the poultry house and from the ceiling to the floor. Do not work with a water pressure of more than 10 to 12 bar.

Choose disinfectants with a broad range of efficacy. They should be effective against bacteria as well as against fungus. If you had extraordinary problems with the last flock, consult your veterinarian for advice on the right disinfectant to apply.

Picture 8: 6 steps of good cleaning and disinfection procedures (DLG, 2010)

Keep in mind: Disinfection without proper cleaning has no effectiveness. Increasing the concentration of a disinfectant is never a substitute for thorough cleaning. During the disinfectant procedure some problems can occur. These particularly include the following:

1. Protein error: Occurs if in an unclean environment, the disinfectant reacts with faeces and other dirt before it can actually react with bacteria or other infectious agents

2. Soap mistake: Disinfectants can be inactivated if they react with residues of cleaning agents. Therefore, it is important to rinse the facility with clear water after cleaning and to dry it thoroughly.

3. Temperature mistake: Some substances like Aldehydes do not work with temperatures which are below 10°C. The activity of many disinfectants improves significantly as the temperatures rise.

To make sure that the cleaning procedure was effective, the results should be tested either by your veterinarian or by your own quality department. The following figures shown in table 2 and picture 9 can be treated as guidelines where bacterial loads are concerned.

Table 2: Microbial contamination of surfaces before and after cleaning and disinfection (benchmark)

Picture 9: Bacterial load before and after cleaning and disinfection (DLG, 2010)

Water and Feed

Water and feed as well as their distribution systems are carriers for pathogens into the poultry facilities. These are often overlooked since farm and production managers focus their efforts on monitoring other management tools.

It is important to integrate water lines, silos and feeding chains into the biosecurity program so as to maximize cleanliness, edibility and potability of feed and water.

Clean and disinfect water lines regularly, especially before and after each treatment with vitamins, vaccination and medication. If this is not performed, a biofilm will build up which can harm the quality of your water. Pathogens like E.Coli, Salmonella can accumulate very easily in biofilms.

Ways to keep the water lines mechanically clean include the use of pulsed water or with special water lines where the water is constantly in motion and little particles and sediments cannot stick on the walls of the pipes. The other possibility to maintain the hygienic status of the water lines on a high level is to treat the water chemically.

Chlorination

• Eliminates bacteria and many viruses

• Most effective in warm water > 18 °C

• Can affect the potency of medication and vaccines

• Concentrations > 5% can harm metal equipment and gaskets

Chlorine dioxide

• No interactions known with medication

• Improves digestive health of the flock

Organic acids

• Reduce the pH value of the water

• Improve digestive health of the birds

• Single acid application can cause slime

formation and block pipelines and nipples. High dosages of single acids can damage water system and also be fatal to the birds

• Organic acids are also a tool to reduce bacterial load in feed

Caution: If the pH value of the water drops to a low level, this will have a negative impact on water intake and can have a negative effect on the equipment as well as vaccines and medication.

The water quality has to be checked on a regular basis. If the water is supplied by an own well, make sure that the samples of water are examined at least twice a year. Feed has to always be of best quality. Establishing a quality monitoring program helps to assure and to monitor nutrient content, microbial and mycotoxin contamination. One of the key factors is to store supplements hygienically to avoid contamination during storage.

Besides storage, clean feed can also be contaminated during transportation. Therefore, it is important to include trucks into the biosecurity regime. The feed supplier has to be certified and controlled. He should be able to perform heat treatment as a tool of sanitation, although very high temperatures might have an impact on the quality and may reduce the nutrient value of the feed. Retain a sample and bill of each delivery to have traceability in the event of a disease outbreak.

Rodent Control

Rodents are attracted to poultry facilities by feed, water and environmental conditions in the barn. They contaminate poultry facilities with faecal excretions and are major vectors and reservoirs of pathogens; especially Salmonella. Therefore, having an effective vermin control in place is a big advantage. Take expert advice and audit the success of the monitoring program regularly.

New Technical Guide Biosecurity & Hygiene

We are pleased to introduce our latest Technical Guide on “Hygiene and Biosecurity” where all the discussed topics have been compacted for you. The guide is available in English, German and Spanish. Please contact our marketing department: marketing@ltz.de to place your orders for the same.

Djanet Ould-Ali, Technical Service

Photos courtesy of (l-r): Ms. Hannah Dunn, Mr. Ian Dunn, Ms. Norrie Russell

It is probably not upper – most in your mind when you dye eggs for Easter that you are depending on an invisible structure called the cuticle being present.

The amount of change in colour you see depends on how much cuticle is present on the egg. Having colourful Easter eggs is good news, but more importantly the cuticle prevents bacteria entering the egg. This reduces the chance bacteria can reach the developing chick if the egg is fertile and keeps the eggs we eat safe.

With industry we are developing tools which are more practical, although less colourful, to measure the amount of cuticle on an egg. This will allow genetic selection to improve the cuticle and improve biosecurity for poultry.

Ian Dunn Ph.D