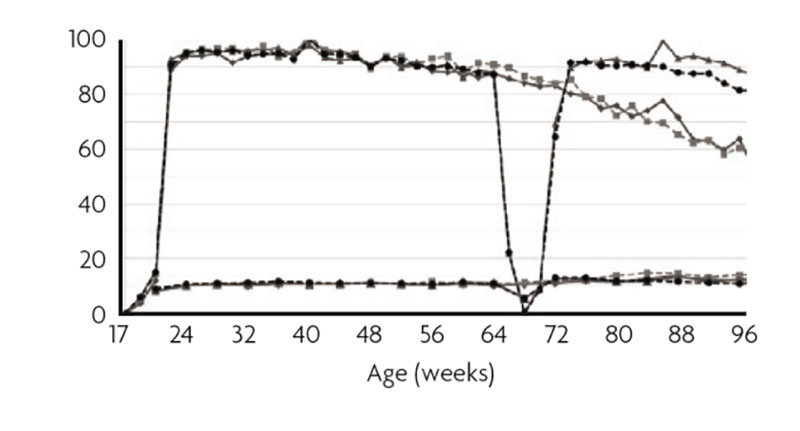

Fig. 1. Extended production cycle with/without forced moulting (North Carolina Test Station – USA)

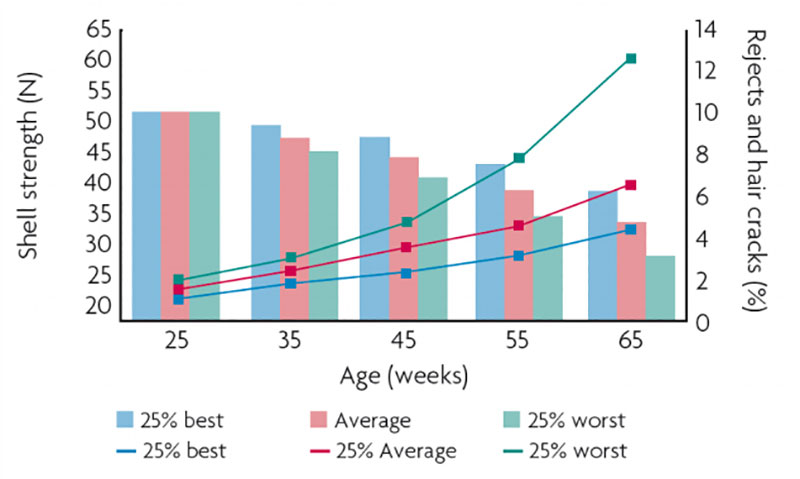

Modern commercial layers and breeders have the potential to produce a large numbers of eggs. Commercial layers producing noticeably above 330 eggs in a single laying cycle of 12 months is no exception under various field conditions. Meat type breeders have also become more prolific during the last decades, easily producing up to 180 hatching eggs in 40 weeks of production. Most performance tables for commercial layers give standards above 80 weeks of age, but today many commercial layer flocks are kept up to 100 weeks or more. In the near future laying flocks will be kept for longer production cycles, which requires more attention of all parties involved to maintain an acceptable eggshell quality towards the end of lay. The greatest challenge that most table egg producers and breeder farmers are facing is to maintain optimal eggshell stability. At the end of production eggshell quality often deteriorates considerably, leading to substantial economic losses for farmers and hatcheries. Under field conditions some commercial layer farms manage to keep the rejected eggs below 5%, whereas others have more than 10% broken and (hair-) cracked eggs (Fig. 2). This wide variation indicates that several factors are involved in maintenance of good eggshell quality.

Factors affecting eggshell stability

A wide range of different influences affect the shell formation in the hen and consequently the possibility that the egg suffers any damage after it has been laid. The choice of the right strain (genetics) is a decisive factor. Numerous tests by stations worldwide and comparisons by major egg grading and packing companies show significant differences in rejected eggs between different layer breeds. It is well known that with increasing age of a hen shell quality usually deteriorates, however, not all layer strains show the same decline in shell strength. Management procedures applied by the farmer, like lighting and feeding programs, paying attention to egg collection

Fig. 2. Variation of shell breaking strength and percentage of cracks between individual farms in the Netherlands

and handling with care afterwards have a major impact on actual egg harvest per farm. Prevention of heat stress under hot weather conditions is crucial to safeguard production and egg quality. Correct climate control supported by feed supplementation will greatly contribute to improved shell quality. The health status of a flock needs to be safeguarded by a well designed vaccination program and comprehensive biosecurity. Many common diseases like infectious bronchitis, Newcastle disease and mycoplasma infection may cause substantial production losses and severely affect shell stability. The right equipment is also important to prevent eggs from breaking after being laid. Cage (floor) properties, egg conveyor belt alignments, nests with good bedding and a state-of-the-art grading and packing machine are important technological issues. Finally, a well balanced feeding program with all nutrients reflecting the birds requirements during different phases of life is essential to allow the bird to lay ‘well packed’ eggs according to their potential. In this article only two major factors affecting shell strength will be addressed. First of all the contribution of genetics to improve shell quality and secondly how the nutritionist can support the production of stronger shells.

Genetics

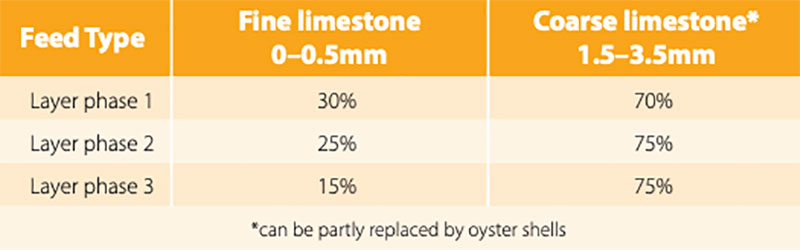

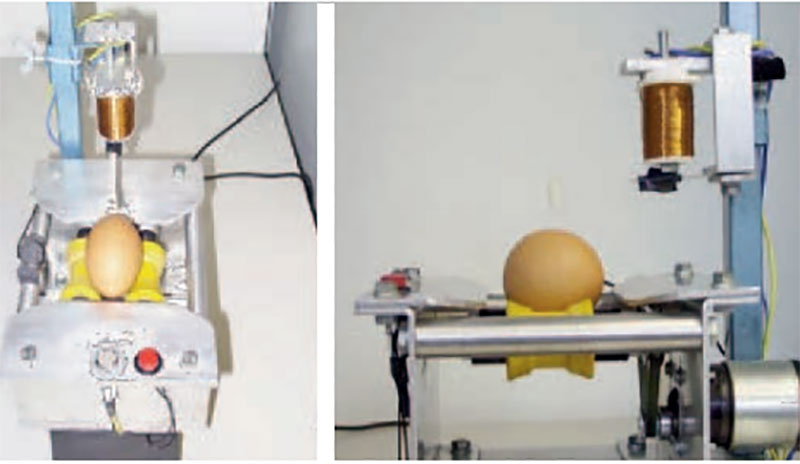

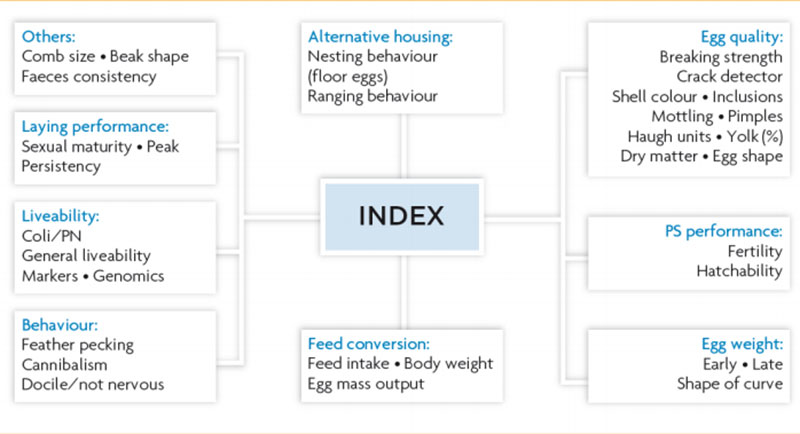

Leading layer-type breeding companies have been selecting for decades for improved productivity and efficiency. Of course egg quality traits have not been neglected. Nowadays, a large number of traits are collected on pure line level in the pedigree farms. All those traits need to be included in a so-called index in order to be able to make a balanced selection of the candidates for the next generation. Several methods for measurement of eggshell stability are applied, however, only two have proven to be most effective. The use of devices measuring static breaking strength and crack detector for dynamic stiffness have greatly contributed to improved shell stability. Both traits have favourable correlations with most other performance traits and have a moderate heritability which allow the genetic improvement of shell stability.Table 1. Recommended particle size distribution of limestone for laying hens (LOHMANN TIERZUCHT Management Guide).

Nutrition

Comparison of eggshell quality properties in the Netherlands revealed a wide variation between different feed manufacturers. Despite the fact that all breeding companies publish feed recommendations for their strains, each feed company usually designs their own in-house feed recipes. In order to compose a feed which allows the birds to produce strong shelled eggs, several issues need to be considered.

Hot weather conditions

In hot climates where heat stress has a major impact on productivity and shell stability, additional actions are required to support the laying hens. Due to the combination of reduced intake of nutrients and respiratory alkalosis due to panting, shell formation is at risk. Addition of 2-3 kg sodium bicarbonate per ton of feed has proven to balance the alkalosis and contribute to stronger shells. Micro-ingredients like zinc, copper, chromium and manganese which play an essential role at the shell formation should be increased under heat stress. Finally supplementation of vitamin C and E helps the birds to cope with high temperatures.

Calcium supply

Most companies use limestone or (oyster-) shells as the main source for calcium carbonate. Besides issues like ratio of calcium release (solubility), first and foremost is the correct particle size distribution of the calcium source. In particular, the fraction of coarse particles should be sufficient. A feed with too high percentage of fine and medium sized particles will cause more broken eggs compared to feed with coarse particles.

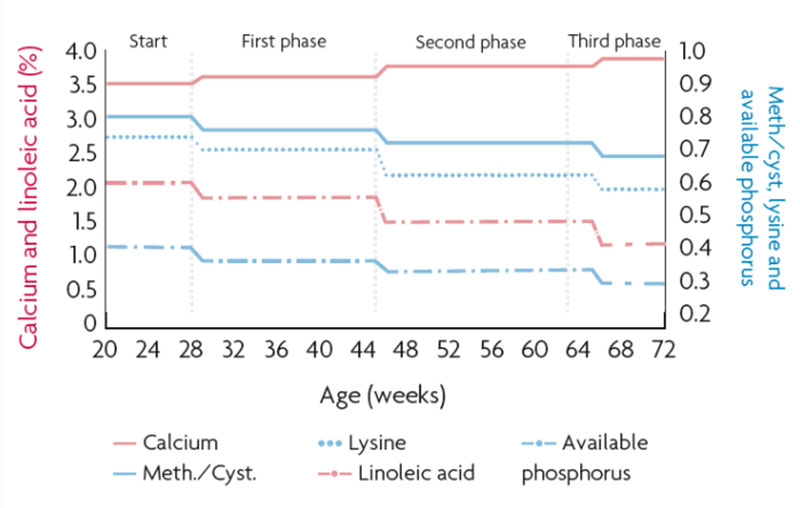

Phase feeding program

Throughout the production period egg weight normally increases and production gradually decreases after peak performance has been reached around 25 weeks of age. In order to fulfil the nutrient requirement in the different stages of life a tailor-made phase feeding program has been designed. The basis of such a program is an increase in calcium content with time, as both utilisation/absorption decreases with age and egg size increases. The available phosphorus level gradually decreases towards the end of lay. Protein- (digestible amino acids) levels also decrease as birds tend to eat more when they grow older. Methionine levels which have a direct impact on egg weight also decrease in line with protein in order to prevent oversized eggs which are more likely to crack. A phase feeding program needs to be applied early enough during the laying period in order to prevent oversized eggs. Layer birds adjust daily feed intake mainly in relation to their energy demand, furthermore increase in daily feed intake needs to be prevented. Overconsumption may lead to oversized eggs. Usually a constant level of energy of the feed throughout the phase feeding program is used under field conditions. The active form of vitamin D3 (1,25-Hydroxycholecalciferol) is essential for correct eggshell formation in the oviduct. Vitamin D3 is converted in two steps in the liver and kidneys to its active form. Birds that suffer from so-called fatty liver syndrome or have kidney damage benefit from supplementation of the active form of vitamin D3 in the feed. Taking care of liver health will therefore contribute to a good eggshell quality even in aging flocks.

Summary

Layers and breeders have a genetic potential for a high egg output. In order to produce mainly saleable and settable (hatching) eggs, eggshell stability is a crucial trait. Both genetics and balanced nutrition play an important role to maintain good eggshell quality. Geneticists have succeeded to combine a prolonged production period with good eggshell stability until the end of lay. Specially designed devices for measurement of shell are used to accurately distinguish hens laying strong shelled and weaker eggs. For the nutritionist hot climate conditions are an additional challenge. In order to maintain production of premium class eggs, rations need to be supplemented with extra micro-ingredients, vitamins C and E and sodium bicarbonate. A socalled phase feeding program with different rations during the production period is essential to safeguard performance. The main targets are to maintain a good eggshell quality, control egg size and balance nutrient supply to actual requirement. Coarse limestone particles are essential for a continuous calcium supply during the shell formation. Vitamin D3, converted by the liver and kidneys is required for eggshell formation in the shell gland.

Ron Eek

Device for the measurement of dynamic stiffness.

Fig. 4. Example of a four phase feeding program for layers